Communication cable processing extruder with crushing function

A technology of communication cables and extruders, applied in communication-related fields, can solve problems such as low production efficiency, inconvenient use, and easy blockage of filter plates, and achieve the effects of easy replacement and cleaning, improved production efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

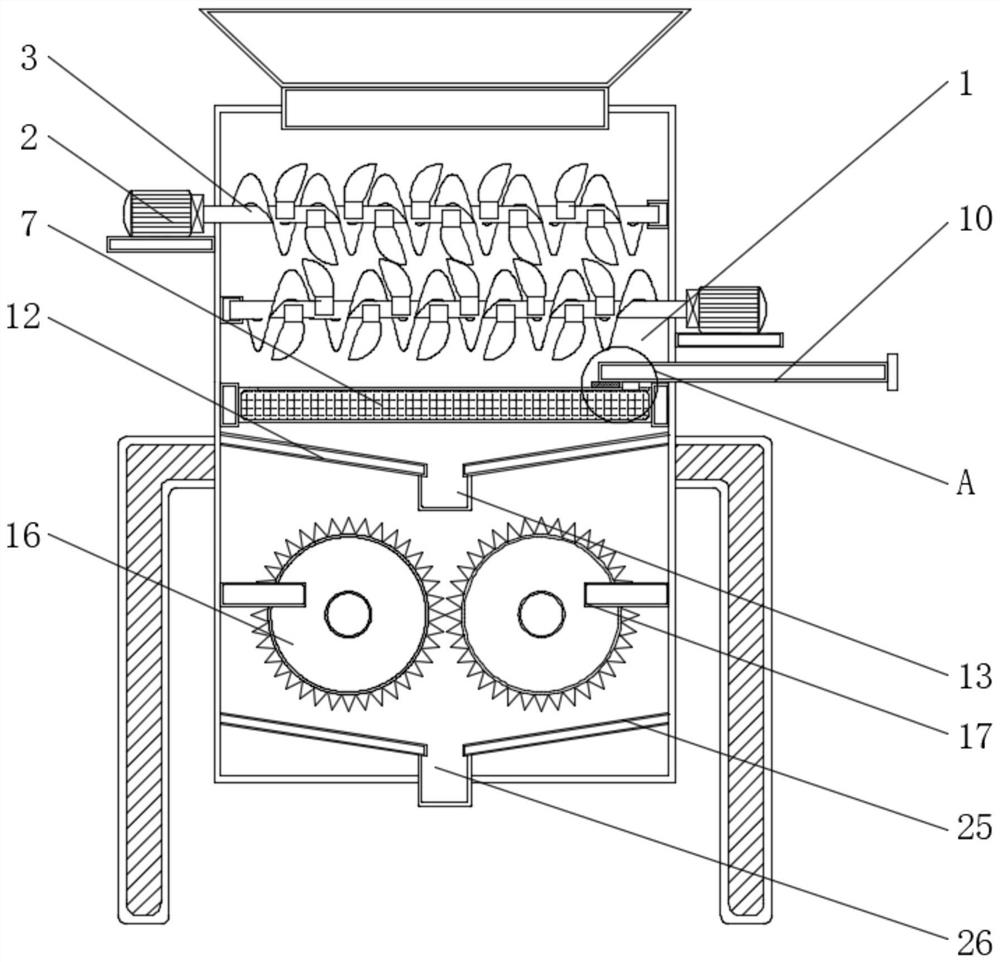

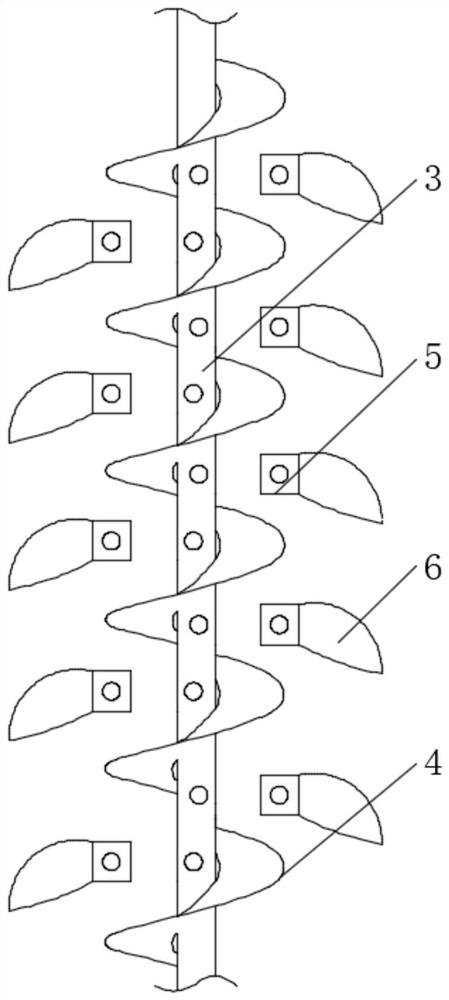

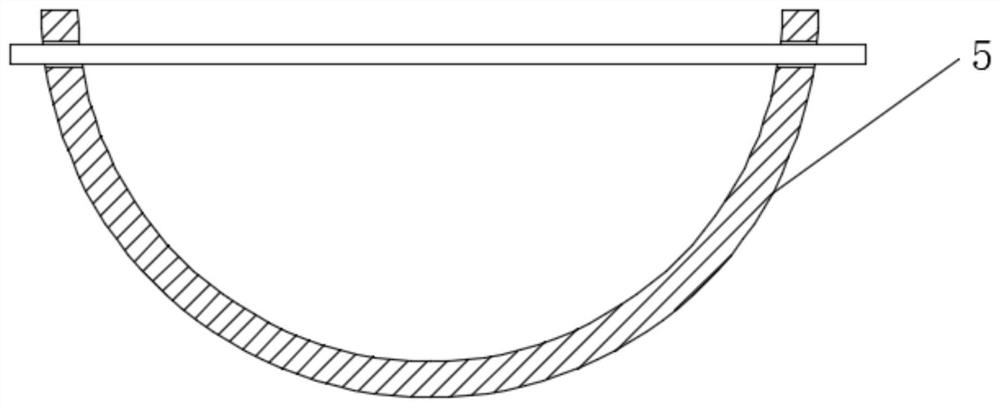

[0037] see Figure 1-7 , in this embodiment: a communication cable processing extruder with a pulverizing function, including an extrusion box 1 and a second drive motor 14, a first drive motor 2 is installed on the side wall of the extrusion box 1, and the first The output end flange of the driving motor 2 is connected with the first rotating shaft 3, the outer wall of the first rotating shaft 3 is respectively provided with a cutting knife 4 and a mounting frame 5, and the inner side of the cutting knife 4 is provided with a mounting frame 5, and the outer wall of the mounting frame 5 is welded There is a crushing knife 6, and a filter plate 7 is welded in the middle of the inner wall of the extrusion box 1, and the top edge of the filter plate 7 is provided with a first chute 8, and the inside of the first chute 8 is provided with a first slider 9, and the second A push rod 10 is welded on the top of a slider 9, a first guide plate 12 is welded below the side wall of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com