Electronic gear shifting handle mounting structure and assembling method

An installation structure, electronic shifting technology, applied in the direction of control device, transportation and packaging, vehicle parts, etc., can solve the problems of damage to electrical connectors, large installation force, easy damage or degradation of elastic parts, etc., to achieve convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

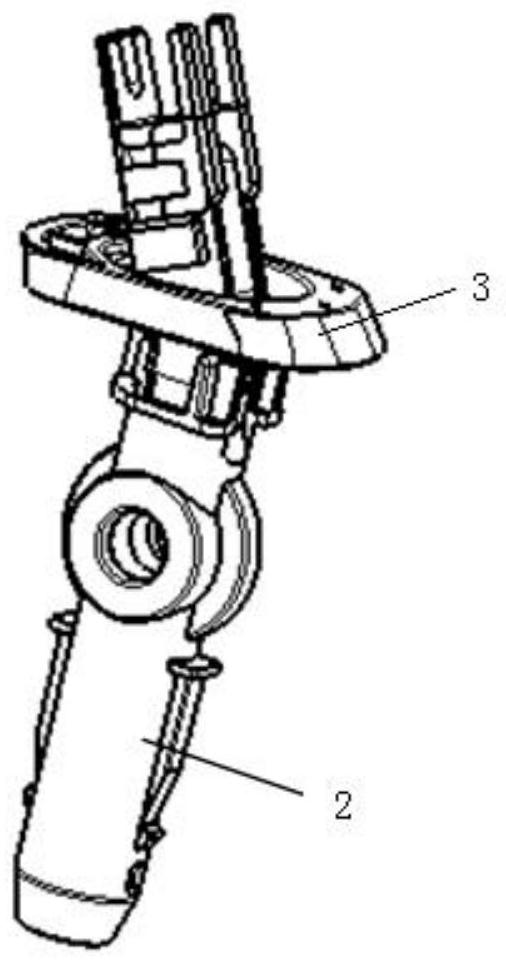

[0041] The matching form of the lock ring and the stop rod: according to Figure 7 The direction of view, after the assembly is completed, the relative position of the lock ring and the stop rod is as follows: Figure 7 In the state shown in the middle figure, the first limit rib 3-1 of the lock ring 3 is rotated to the bottom of the limit protrusion 2-1 of the stop rod 2 to ensure that the stop rod cannot move downward relative to the lock ring (i.e. the handle), which can ensure that the handle cannot be disengaged from the stop lever; Figure 7 The picture in the middle shows the state when the stopper rod 2 and the lock ring 3 are assembled. Relative to the middle picture, the lock rotates 30° counterclockwise around the axis of the stopper bar. At this time, the first limit rib 3-1 of the lock ring has been rotated to a proper position to ensure the limit There is no limit structure under the protrusion 2-1, and the stop rod 2 can be normally separated from the lock ring...

Embodiment 2

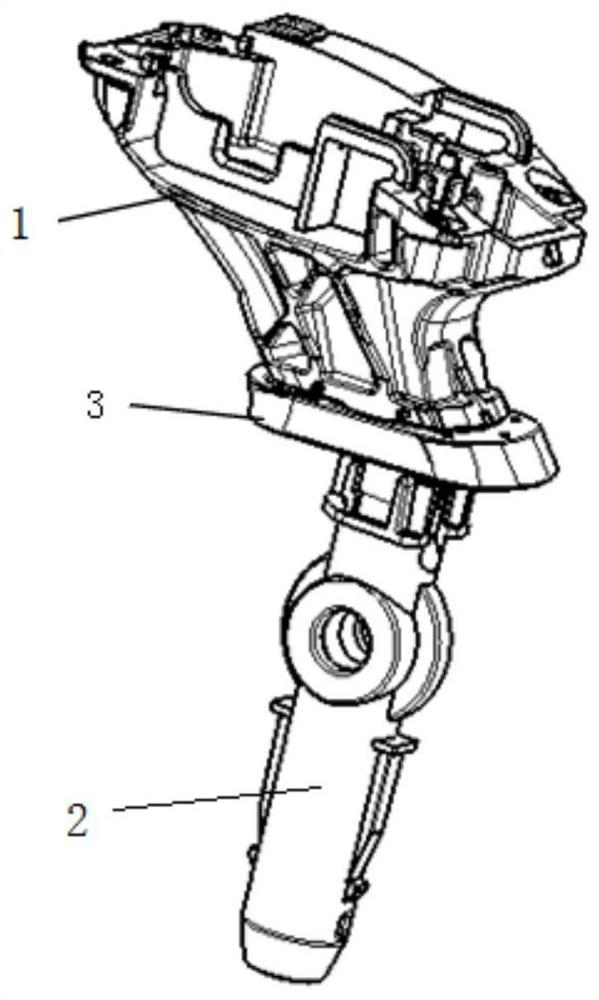

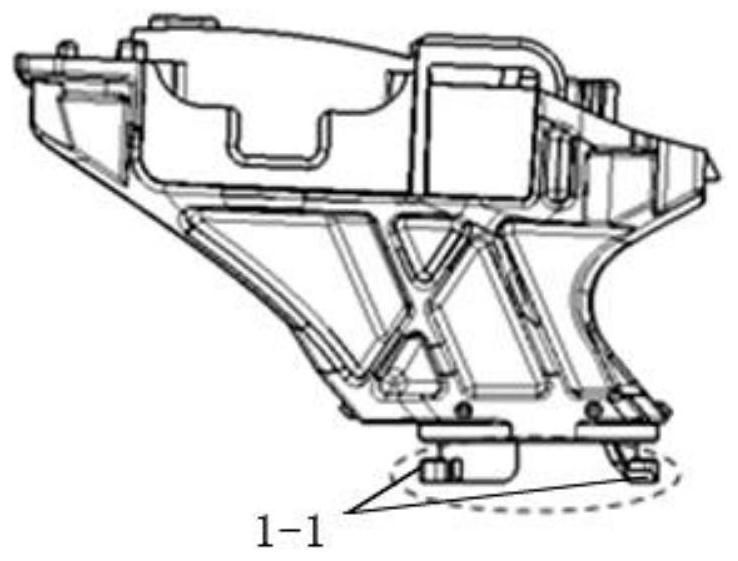

[0043] The matching form of the lock ring 3 and the handle skeleton 1: according to Figure 8 the view direction, Figure 8 , Figure 9 It is the state before assembly. At this time, the second limit rib 3-2 of the lock ring 3 is disengaged from the two limit bosses 1-1 of the handle frame 1, and the lock ring can be disengaged from the handle frame 1, but in order to lock before assembly The ring does not get loose from the handle skeleton, and a raised rib 1-2 ( Figure 9 shown); Figure 10 , Figure 11 For the state after the assembly is locked, according to Figure 9 In the direction of view, rotate 30° counterclockwise from the loosened state to the locked state. At this time, the second limit rib 3-2 of the lock ring 3 rotates to the top of the limit boss 1-1 of the handle frame to ensure that the handle frame 1 It cannot move relative to the lock ring 3 in the axial direction, and at the same time, the raised rib 1-2 on the handle frame 1 just rotates into the limi...

Embodiment 3

[0045] The overall cooperation form of the lock ring, the retaining rod and the handle frame: in combination with Embodiment 1 and Example 2, the position of the lock ring rotation ensures that the second limit rib 3-2 is on the upper part of the limit boss 1-1 of the handle frame. Simultaneously the first limiting rib 3-1 is at the bottom of the limiting projection 2-1 (the limiting projection 2-1 of the retaining bar and the limiting boss 1-1 of the handle skeleton are arranged according to the rotation of 90°), at this time Connect the handle frame with the stop rod as a whole through the lock ring, such as Figure 13As shown; 30°clockwise rotation is the loosened state. At this time, the second limiting rib 3-2 of the lock ring avoids the limiting boss 1-1, and the first limiting rib 3-1 avoids the protrusion of the stop rod at the same time. Block 2-1, the blocking rod can be separated from the handle frame (the lock ring will not fall off from the handle frame due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com