Dot matrix pasting method and dot matrix pasting tool

A dot matrix and tool technology, applied in the field of dot matrix method and dot matrix tool, can solve the problems of low labeling efficiency and easy occurrence of safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

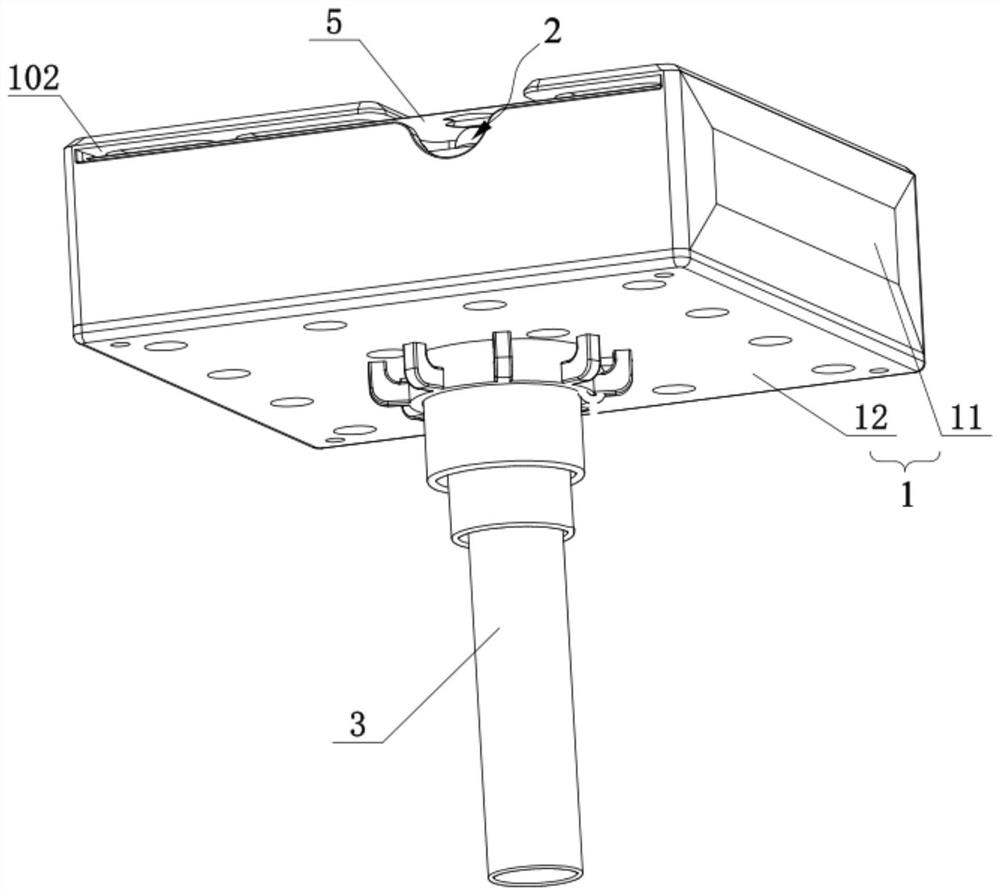

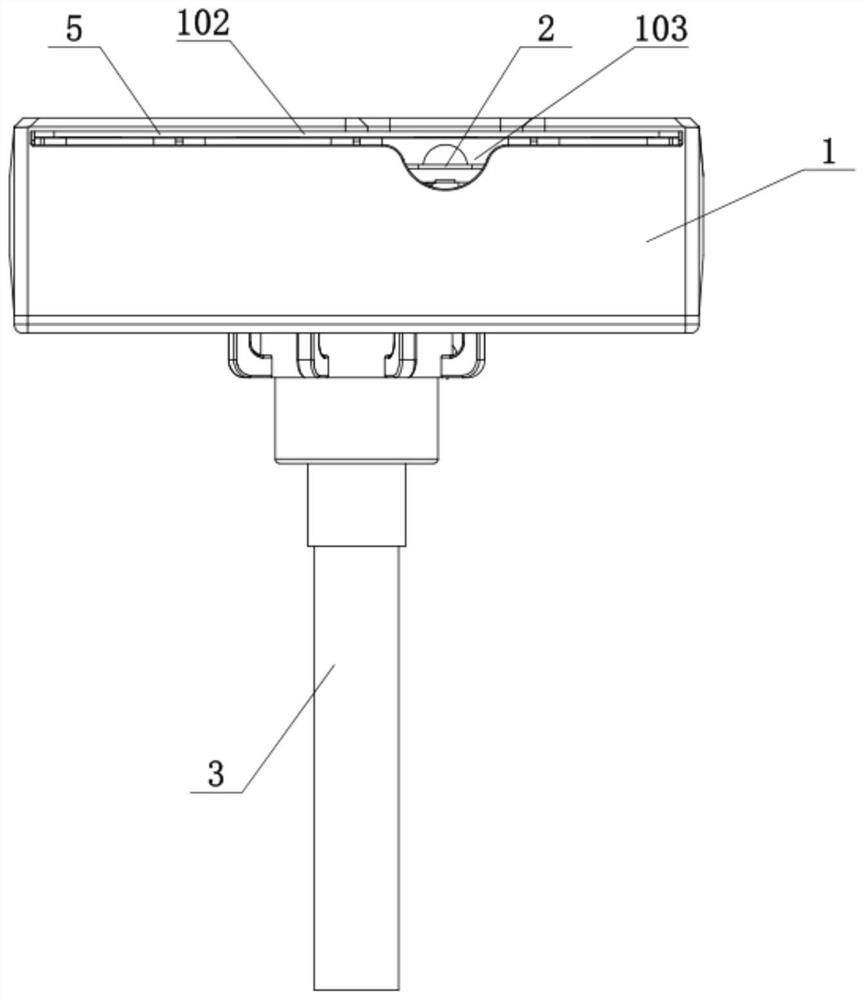

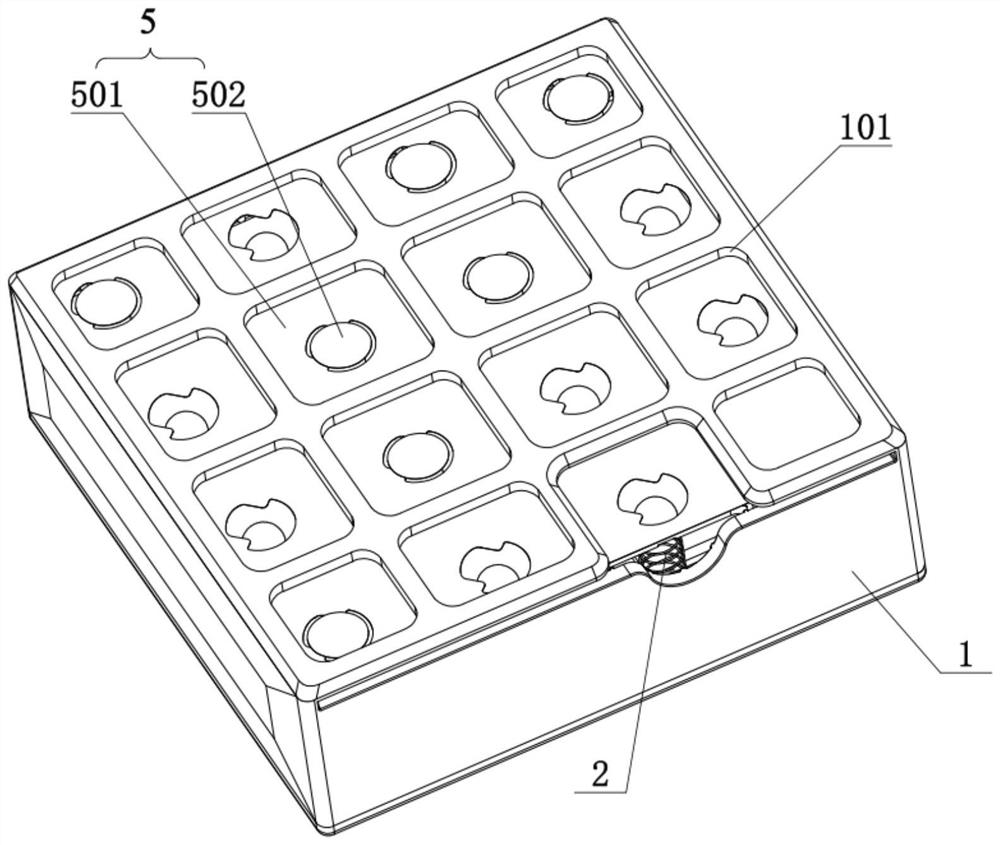

[0067] This embodiment provides a simple and hand-held sticking dot matrix tool, such as Figure 1 to Figure 6 As shown, the dot matrix sticking tool can assist labelers to stick the dot matrix on the dot matrix unit 5 at a high place, such as the top surface of the floor or the higher place of the equipment. The dot matrix is formed by a plurality of marking points 502 according to specific Formed by regular arrangement (such as rectangular array or circular array). Using the dot matrix tool, labelers can stand on the ground and hold the dot matrix tool to label high places, which not only has high safety, is not prone to safety accidents, but also has high labeling efficiency.

[0068] In this embodiment, the dot matrix unit 5 further includes a base layer 501 . Optionally, the base layer 501 may be a release paper, and the marking points 502 are bonded on the base layer 501 . At this time, both sides of the marking point 502 are sticky, one side is the first adhesive sur...

Embodiment 2

[0110] On the basis of the first embodiment, this embodiment proposes a dot matrix sticking tool, which is basically the same as the dot matrix sticking tool in the first embodiment, except for the following two points. The first difference is: the structures of the dot matrix units 5 are different. In this embodiment, the dot matrix unit 5 also includes a base layer 501. Optionally, the base layer 501 can be a release paper, and a plurality of accommodating holes are arranged on the base layer 501, and a plurality of marking points 502 of the dot matrix correspond to each other. It is located in multiple accommodating holes, and is connected with the inner walls of the accommodating holes through breakable points. Under the action of external force, the breakable point breaks, and the marking point 502 and the base layer 501 can be separated. At this time, only one side of the marking point 502 is sticky, which is the first adhesive surface, and the first adhesive surface ca...

Embodiment 3

[0151] On the basis of the first embodiment, this embodiment proposes a dot matrix sticking tool, which is basically the same as the dot matrix sticking tool in the first embodiment, except for the following two points. The first difference is: the structures of the dot matrix units 5 are different. In this embodiment, the dot matrix unit 5 also includes a base layer 501. Optionally, the base layer 501 can be a release paper, and a plurality of accommodating holes are arranged on the base layer 501, and a plurality of marking points 502 of the dot matrix correspond to each other. It is located in multiple accommodating holes, and is connected with the inner walls of the accommodating holes through breakable points. Under the action of external force, the breakable point breaks, and the marking point 502 and the base layer 501 can be separated. At this time, only one side of the marking point 502 is sticky, which is the first adhesive surface, and the first adhesive surface ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com