An aluminum foil winding device with adjustable tightening degree

A winding device, aluminum foil technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve problems such as troublesome operation, excessively tight aluminum foil winding, and inability to meet the different needs of aluminum foil winding thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

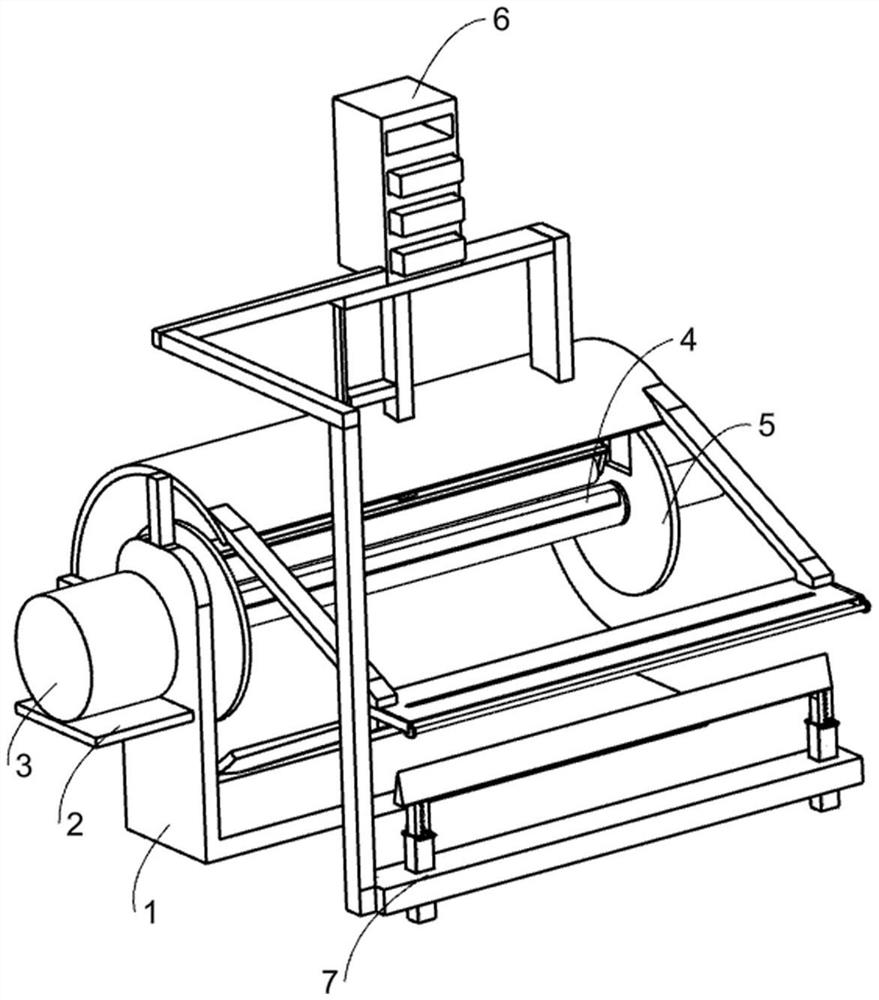

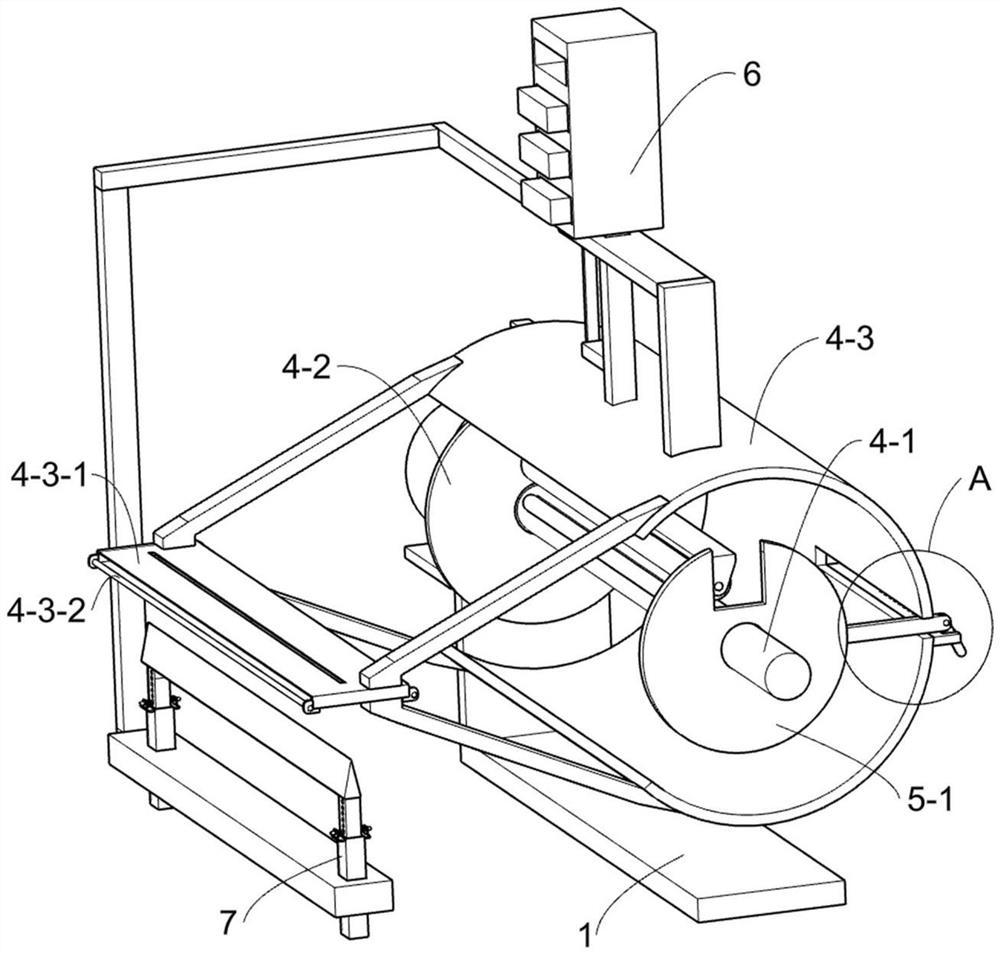

[0022] An aluminum foil winding device with adjustable tightening degree, such as Figure 1-7 As shown, it includes a base 1, a supporting plate 2, a motor 3, a clamping mechanism 4, an adjusting mechanism 5 and a tightening mechanism 6, the supporting plate 2 is fixed on one side of the base 1, and the motor 3 is fixed on the On the upper side of the pallet 2 , the clamping mechanism 4 for clamping the reel is provided on the base 1 , and the adjusting mechanism 5 and the tightening mechanism 6 are both provided on the clamping mechanism 4 .

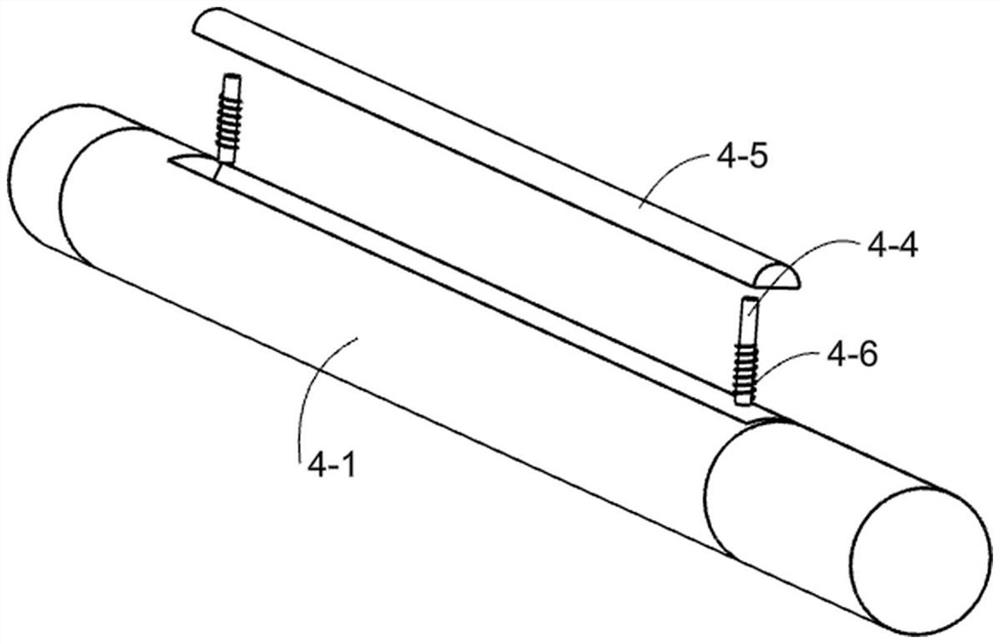

[0023] Further, the clamping mechanism 4 includes a power shaft 4-1, a fixed plate 4-2, an annular frame 4-3, a ferrule 4-3-1, a movable rod 4-3-2, a telescopic rod 4-4, The clamping rod 4-5 and the compression spring 4-6, the power shaft 4-1 is arranged on the base 1 through a bearing and is fixedly connected with the output shaft of the motor 3, and the fixing plate 4-2 is fixedly arranged on the power shaft 4 -1 and close to the bas...

Embodiment 2

[0029] On the basis of Example 1, as Figure 1-2 As shown in and 5-6, the tightening mechanism 6 for adjusting the tightness of the aluminum foil winding is provided on the annular frame 4-3, and the tightening mechanism 6 includes a fixed seat 6-1, a lifting rod 6-2, The lifting frame 6-3, the movable wheel 6-4, the pressure box 6-5, the gravity block 6-6 and the scale 6-7, the fixed seat 6-1 is fixedly arranged on the upper side of the ring frame 4-3, so the One end of the fixing seat 6-1 is provided with a sliding hole, and the lifting rod 6-2 is slidably arranged in the sliding hole. The lifting rod 6-2 passes through the upper part of the annular frame 4-3, and the lifting frame 6-3 Fixed on the lower end of the lifting rod 6-2 and located in the ring frame 4-3, the movable wheel 6-4 is rotatably arranged on the lifting frame 6-3 and the movable wheel 6-4 can enter the moving plate 5-1 In the arc groove on the top, the movable wheel 6-4 is used to press the aluminum foil...

Embodiment 3

[0032] On the basis of Example 2, as Figure 1-2 and Figure 6-7 As shown, it also includes a shearing mechanism 7 for cutting the aluminum foil, the shearing mechanism 7 is arranged on the pressure box 6-5, and the shearing mechanism 7 includes a connecting rod 7-1, a transverse plate 7-2, A fixed frame 7-3, a cutter 7-4, a fixed block 7-5, a toggle rod 7-6, a clamping ball 7-7 and a telescopic spring 7-8, the connecting rod 7-1 is fixed on the pressure box 6 On one side of -5, the horizontal plate 7-2 is fixedly arranged on the lower end of the connecting rod 7-1 and is located below the ferrule 4-3-1, and two symmetrical fixing plates are fixed on the horizontal plate 7-2. Frame 7-3, the cutter 7-4 for cutting the aluminum foil is slidably arranged in the fixing frame 7-3, and eight slots are provided on both sides of the cutter 7-4. One end of the frame 7-3 away from the horizontal plate 7-2 is fixedly provided with two symmetrical fixing blocks 7-5 and the fixing blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com