Aluminum-wood composite window with good impact resistance

An aluminum-wood composite and impact-resistant technology, applied in the field of aluminum-wood composite windows, can solve problems such as frame damage, and achieve the effects of increasing contact area, increasing stability, and reducing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

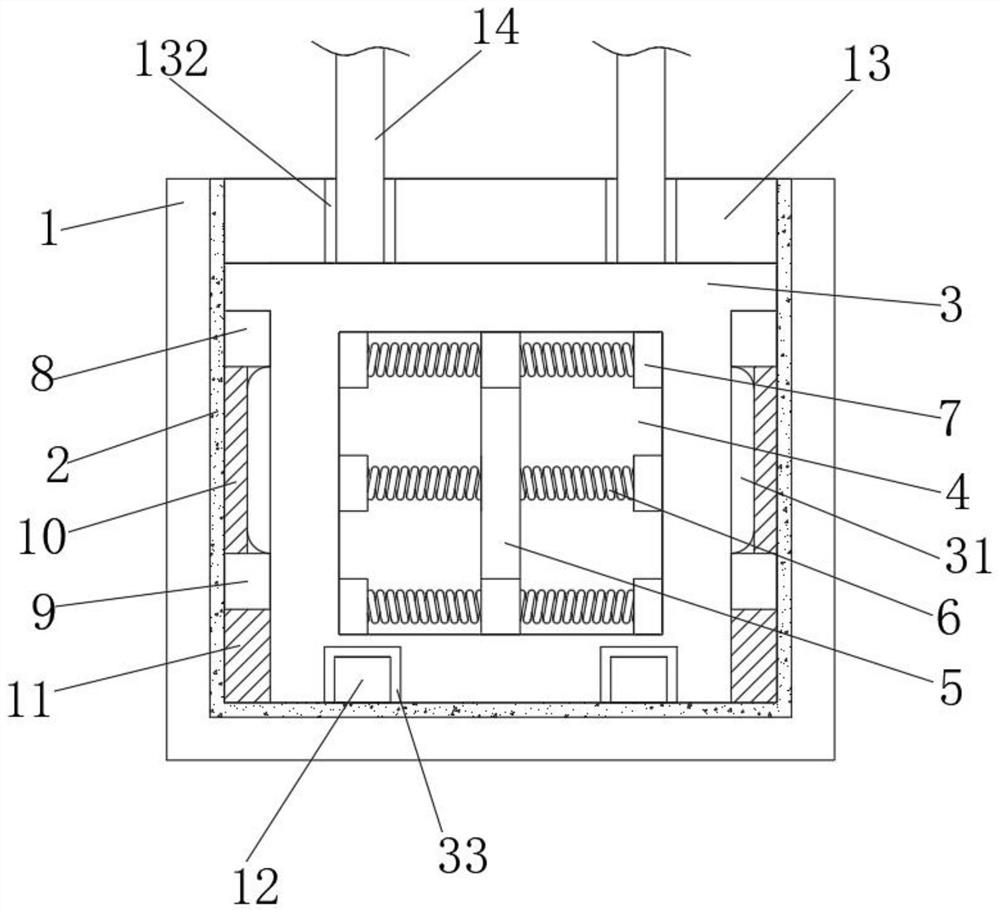

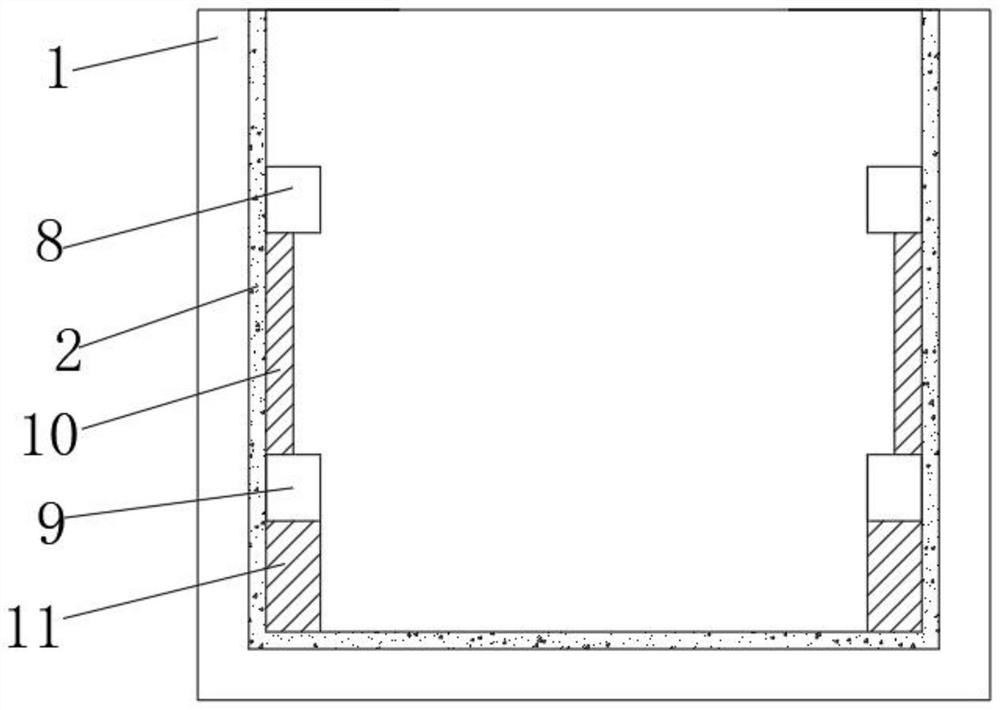

[0026] Example 1: See Figure 1-4 , the aluminum-wood composite window with good impact resistance of the present invention comprises a wooden frame 1 and an aluminum frame 3, the aluminum frame 3 is fixedly plugged into the interior of the wooden frame 1, and the center of the front of the aluminum frame 3 is provided with a weight-reducing groove 4 to reduce the weight. The center between the top and the bottom of the inner wall of the heavy tank 4 is fixedly connected with a stiffener plate 5, and the left and right sides of the stiffener plate 5 are evenly fixedly connected with a shock absorbing spring 6, and the shock absorbing spring 6 is far away from the side of the stiffener plate 5 A backing plate 7 is fixedly connected. When the shock-absorbing spring 6 is in the initial state, the backing plate 7 fits with the inner wall of the weight-reducing groove 4. The inner wall of the wooden frame 1 is fixedly connected with a shock-absorbing plate 2. The left side of the in...

Embodiment 2

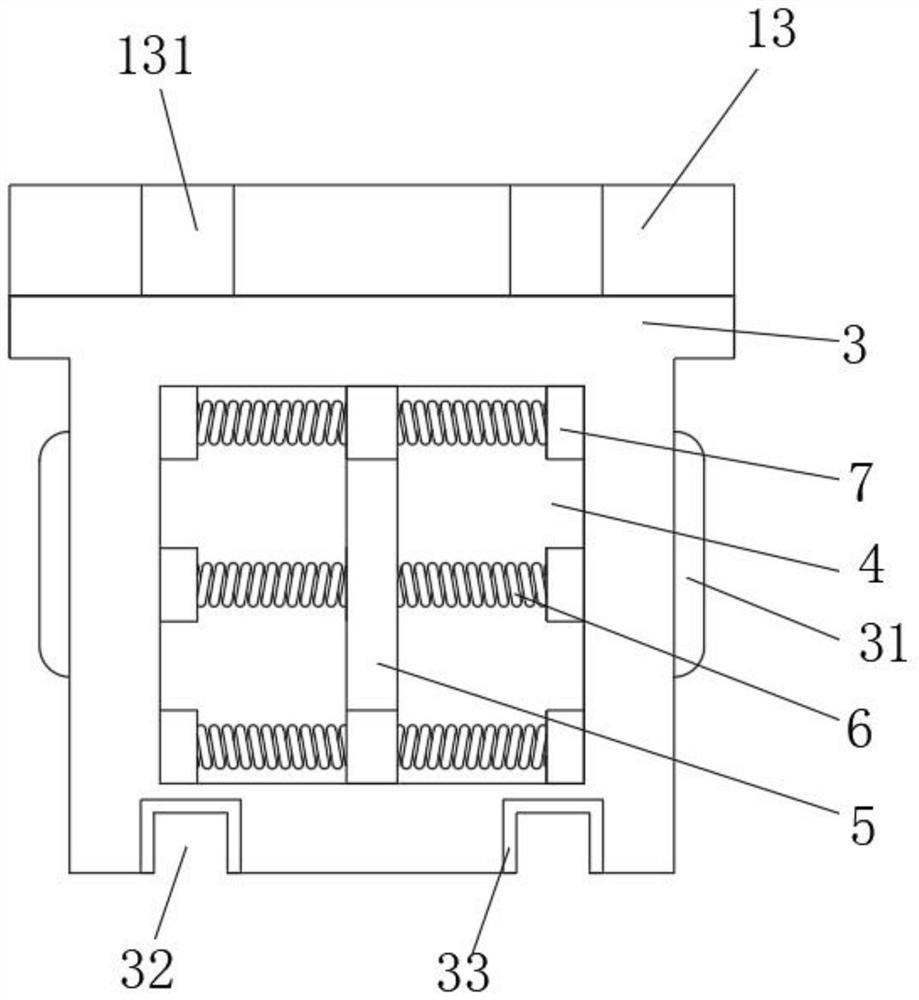

[0031] Example 2: See Figure 5-6 Different from Embodiment 1, the rib plate 5 includes a first rib 51, a second rib 52 and a third rib 53, and the center of the top and bottom of the inner wall of the weight-reducing groove 4 is fixedly connected with the second rib along the longitudinal equidistant. Three reinforcing ribs 53, two rows of third reinforcing ribs 53 are arranged alternately, the first reinforcing rib 51 and the second reinforcing rib 52 are respectively fixed and connected to the front of the first reinforcing rib 51 with the center of the third reinforcing rib 53 as the origin and the back side, the damping spring 6 is respectively located at the center of the first rib 51, the second rib 52 and the third rib 53, and the top of the mounting plate 13 and the positions near the left and right sides are provided with a second mounting groove 15 , the left and right sides of the inner wall of the second installation groove 15 and the position near the top are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com