A high-sensitivity ultrasonic flowmeter based on an ultrasonic transducer and its method

An ultrasonic transducer and ultrasonic flowmeter technology, applied in the direction of volume measurement, measurement of flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of low sensitivity, difficult to integrate, large flowmeter, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

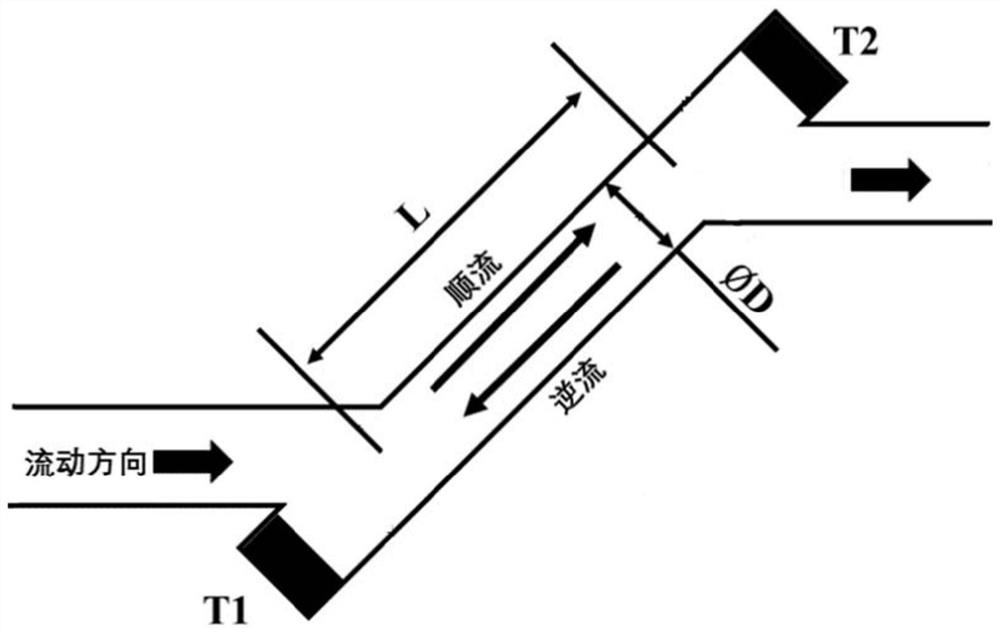

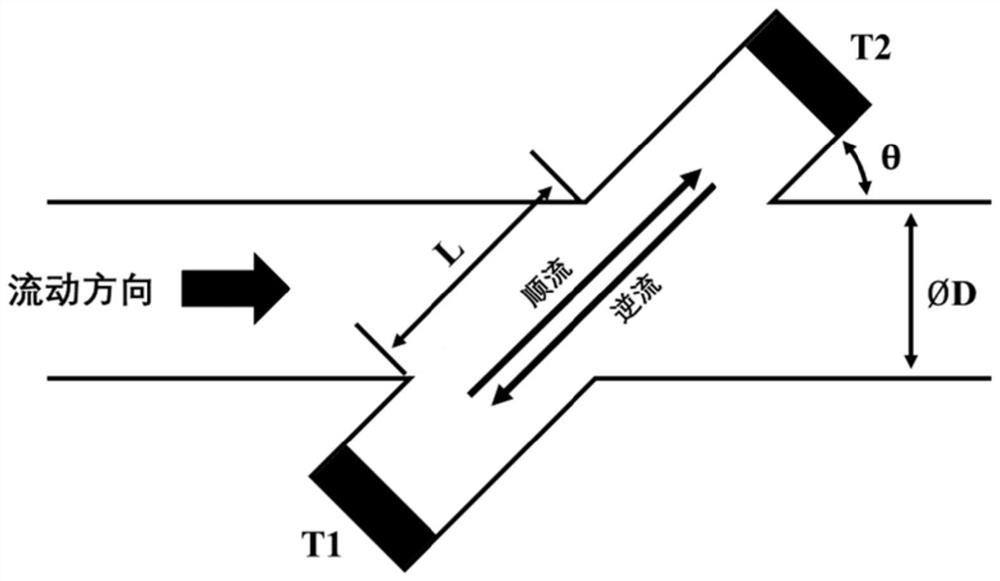

[0057] At room temperature, using traditional ultrasonic flowmeters (θ=45°, D=8mm, L=D / sinθ, such as image 3 shown) and the high-sensitivity ultrasonic flowmeter of the present invention (D=8mm, L is about 150mm, as figure 1 shown) to measure the flow rate of liquid paraffin oil. Wherein, θ refers to the angle between the propagation path of the ultrasonic wave and the flow path of the fluid in the middle section, and in the present invention, the angle θ=0°.

[0058] The results show that the test sensitivity of the traditional ultrasonic flowmeter is 3.5 ns·min / L, and the test sensitivity of the high-sensitivity ultrasonic flowmeter of the present invention is 85.6 ns·min / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com