A Method of Industrial WIP Manufacturing in Discrete Manufacturing Industry Based on Network Planning

A technology of manufacturing industry and network planning, applied in the field of industrial work-in-progress manufacturing in discrete manufacturing industry, can solve the problems of multiple working processes of working nodes, difficult implementation, high development cost, etc., achieve flexible and controllable working process, and shorten processing time , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

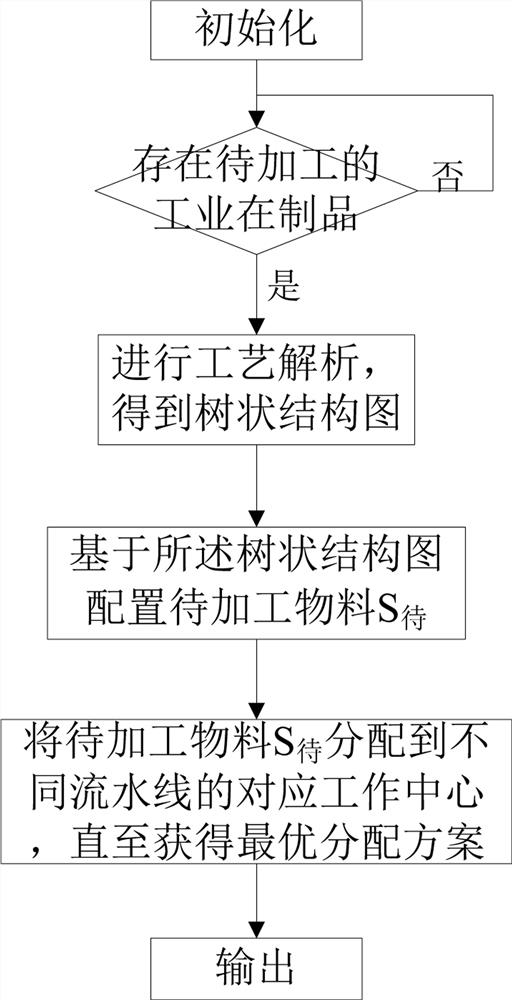

[0040] The invention relates to a method for manufacturing in-process products in discrete manufacturing industries based on network planning. The method includes the following steps.

[0041] Step 1: Initialization.

[0042] In the step 1, the initialization includes:

[0043] Let the objective function f , the number of iterations is iter , the maximum number of iterations is itermax ; ,in, T is the loss time of each path, N is the current number of pipeline lines, P cost is the cost loss of each pipeline, u 1 and u 2 are the weight coefficients respectively, and u 1 + u 2 =1;

[0044] Let the number of work centers of each pipeline be K , the turnover rate of any work center on any pipeline W ij , there are initial materials to be processed in any work center of any assembly lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com