Novel aluminum profile cutting machine

An aluminum profile and cutting machine technology, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment and other directions, can solve the problem of ensuring the verticality of the profile incision and other problems, and achieve the effect of simple structure, ensuring cutting safety and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

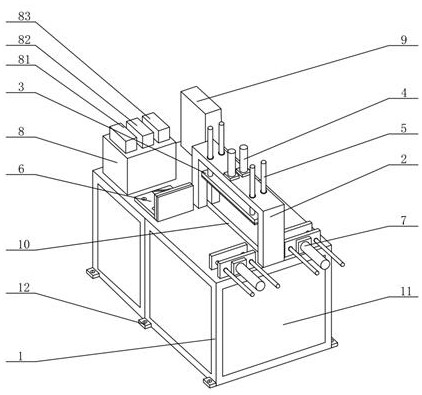

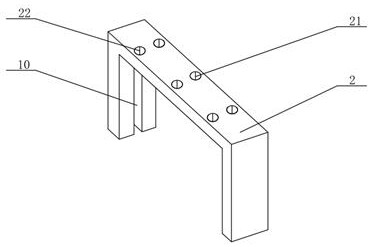

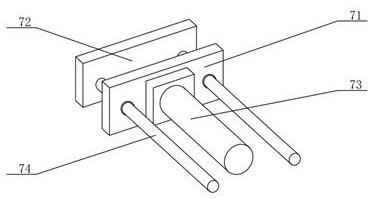

[0021] see Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it includes a base 1, a bracket 2, a pressure plate 3, a lifting cylinder 4, a connecting rod 5, a supporting device 6, a pressing device 7, an oil tank 8, a control cabinet 9, a pedal Switch and cutting device, the support 2 is fixedly connected above the base 1, and through holes 21 and connection holes 22 are evenly arranged above the support 2, and the two through holes 21 are respectively located at the front of the support 2. In the upper middle position, the four connecting holes 22 are located on both sides of the two through holes 21 correspondingly, the two pressing plates 3 are located directly below the inner side of the bracket 2, and the two The lifting cylinders 4 are vertically and fixedly connected directly above the support 2, and the push rods of the two lifting cylinders 4 are respectively fixedly connected with the middle positions of the two pressure pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap