A kind of preparation method of imitation natural stone tile

A technology of imitating natural and ceramic tiles, which is applied in the field of preparation of imitating natural granite tiles, can solve the problems of non-reuse, long forming cycle, waste of natural resources, etc., achieve realistic effects, promote rearrangement and densification, and improve fracture modulus number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

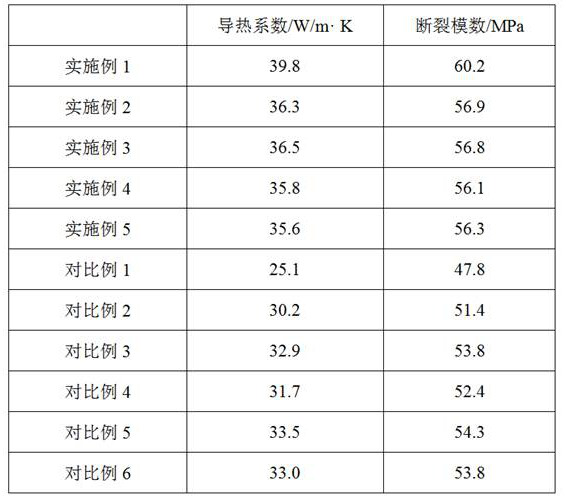

Examples

Embodiment 1

[0036] A preparation method for imitating natural granite tiles, comprising the following steps:

[0037] (1) Preparation of black particles;

[0038] (2) Preparation of red frit particles;

[0039] (3) Preparation of ceramic tile base material;

[0040] (4) Add 30 parts of tile base material, 5 parts of black granules, and 5 parts of red frit granules into the mixer by weight and mix evenly;

[0041] (5) Compress the product obtained in (4) with a molding machine at 55 MPa to obtain a dry billet;

[0042] (6) Sinter the dry blank at 1280°C for 140 minutes, cool it to room temperature, and grind the edges to obtain imitation natural granite tiles.

[0043] In the present embodiment, the preparation method of the black particles is:

[0044] S1: Weigh the following raw materials according to the ratio: 24 parts of kaolin, 10 parts of quartz, 7 parts of porcelain sand, 5 parts of talc, 2 parts of diyttrium trioxide, 2 parts of strontium oxide, 2 parts of ammonium bicarbonate...

Embodiment 2

[0058] A preparation method for imitating natural granite tiles, comprising the following steps:

[0059] (1) Preparation of black particles;

[0060] (2) Preparation of red frit particles;

[0061] (3) Preparation of ceramic tile base material;

[0062] (4) Add 30 parts of tile base material, 5 parts of black granules, and 5 parts of red frit granules into the mixer by weight and mix evenly;

[0063] (5) Compress the product obtained in (4) with a molding machine at 55 MPa to obtain a dry billet;

[0064] (6) Sinter the dry blank at 1280°C for 140 minutes, cool it to room temperature, and grind the edges to obtain imitation natural granite tiles.

[0065] In the present embodiment, the preparation method of the black particles is:

[0066] S1: Weigh the following raw materials according to the ratio: 24 parts of kaolin, 10 parts of quartz, 7 parts of porcelain sand, 5 parts of talc, 2 parts of diyttrium trioxide, 2 parts of strontium oxide, 2 parts of ammonium bicarbonate...

Embodiment 3

[0080] A preparation method for imitating natural granite tiles, comprising the following steps:

[0081] (1) Preparation of black particles;

[0082] (2) Preparation of red frit particles;

[0083] (3) Preparation of ceramic tile base material;

[0084] (4) Add 30 parts of tile base material, 5 parts of black granules, and 5 parts of red frit granules into the mixer by weight and mix evenly;

[0085] (5) Compress the product obtained in (4) with a molding machine at 55 MPa to obtain a dry billet;

[0086] (6) Sinter the dry blank at 1280°C for 140 minutes, cool it to room temperature, and grind the edges to obtain imitation natural granite tiles.

[0087] In the present embodiment, the preparation method of the black particles is:

[0088] S1: Weigh the following raw materials according to the ratio: 24 parts of kaolin, 10 parts of quartz, 7 parts of porcelain sand, 5 parts of talc, 2 parts of diyttrium trioxide, 2 parts of strontium oxide, 2 parts of ammonium bicarbonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com