A method for automatic piecing of ring spinning frame

A jointing method and spinning frame technology, applied to spinning machines, free-end spinning machines, continuous winding spinning machines, etc., can solve the problems of inability to adapt to modern production and low efficiency of manual jointing, and achieve improved jointing efficiency. efficiency, realize industrial automation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

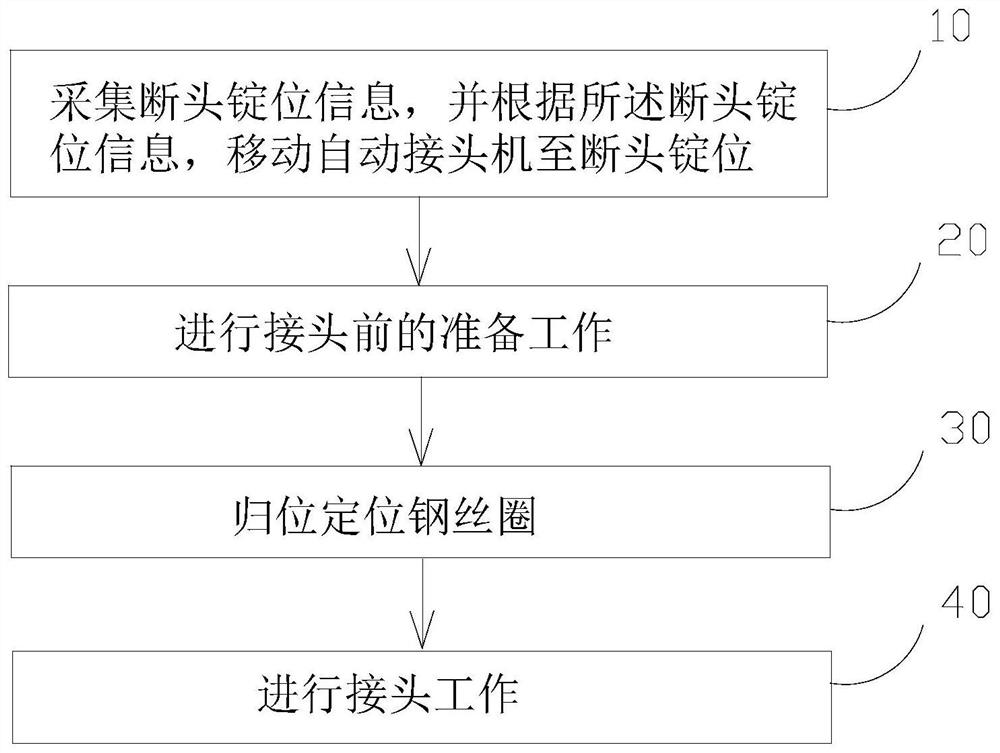

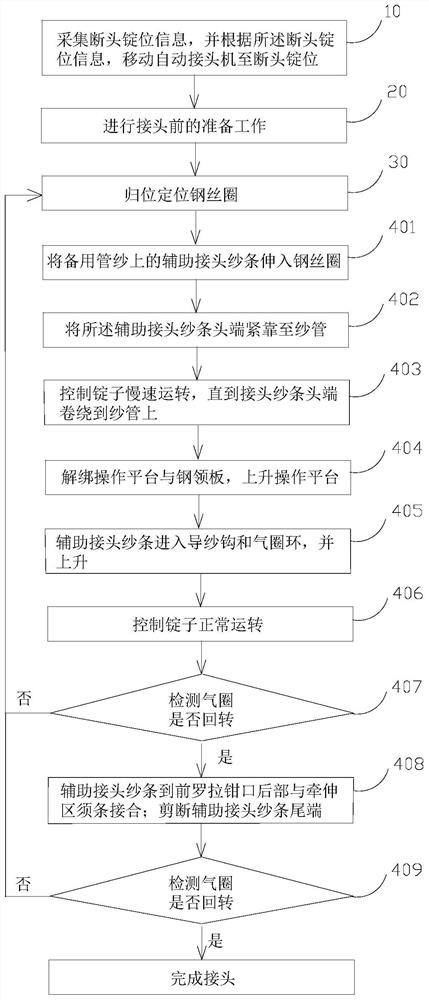

[0035] like figure 1 As shown, a method for automatic jointing of a ring spinning frame according to an embodiment of the present invention includes:

[0036] Step 10) collecting the broken end spindle position information, and moving the automatic splicing machine to the broken end spindle position according to the broken end spindle position information;

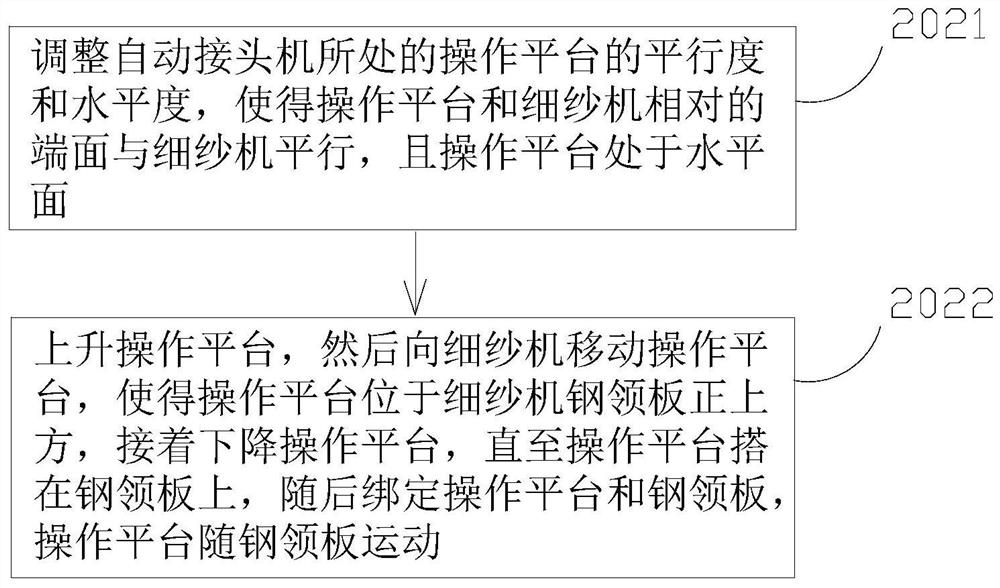

[0037] Step 20) preparing for jointing;

[0038] Step 30) homing and positioning the traveler;

[0039] Step 40) Carry out joint work.

[0040] In the above-mentioned embodiment, the information of the broken end spindle position is firstly collected, the automatic piecing machine moves to the broken end spindle position, and then the preparatory work before jointing is performed, and then the traveler is homing and positioned, and finally the jointing work is performed. The whole me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com