Smoke exhaust fan

A fume exhaust fan and exhaust pipe technology, used in mechanical equipment, oil fume removal, machine/engine, etc., can solve the problems of difficult cleaning of the attachments on the inner wall of the pipe, affecting the rotation speed of the fan, and troublesome maintenance, so as to facilitate the overall management of the equipment. , The effect of maintaining smoke exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

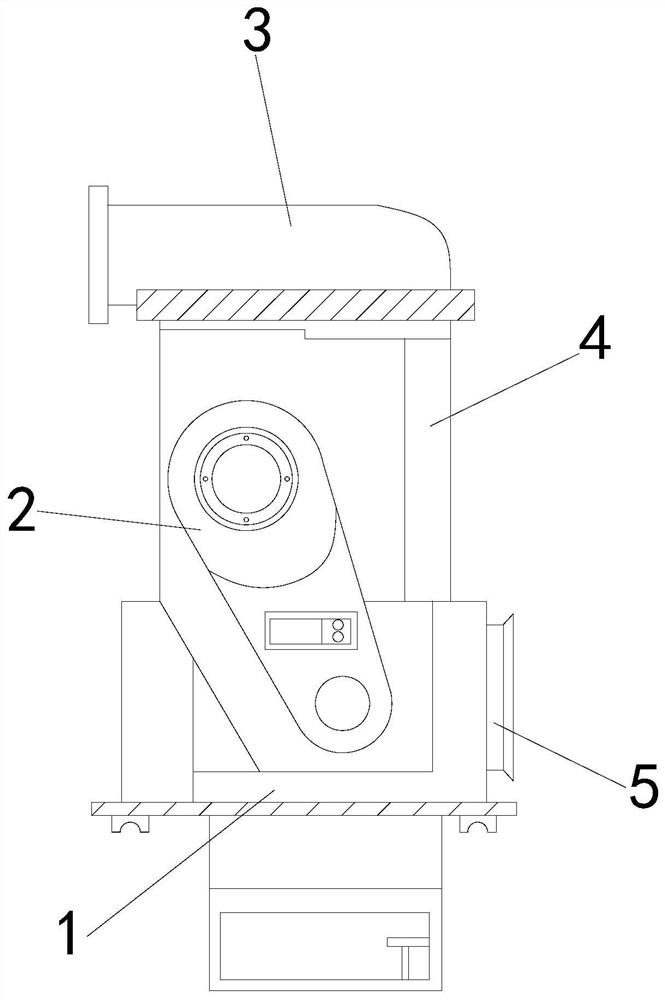

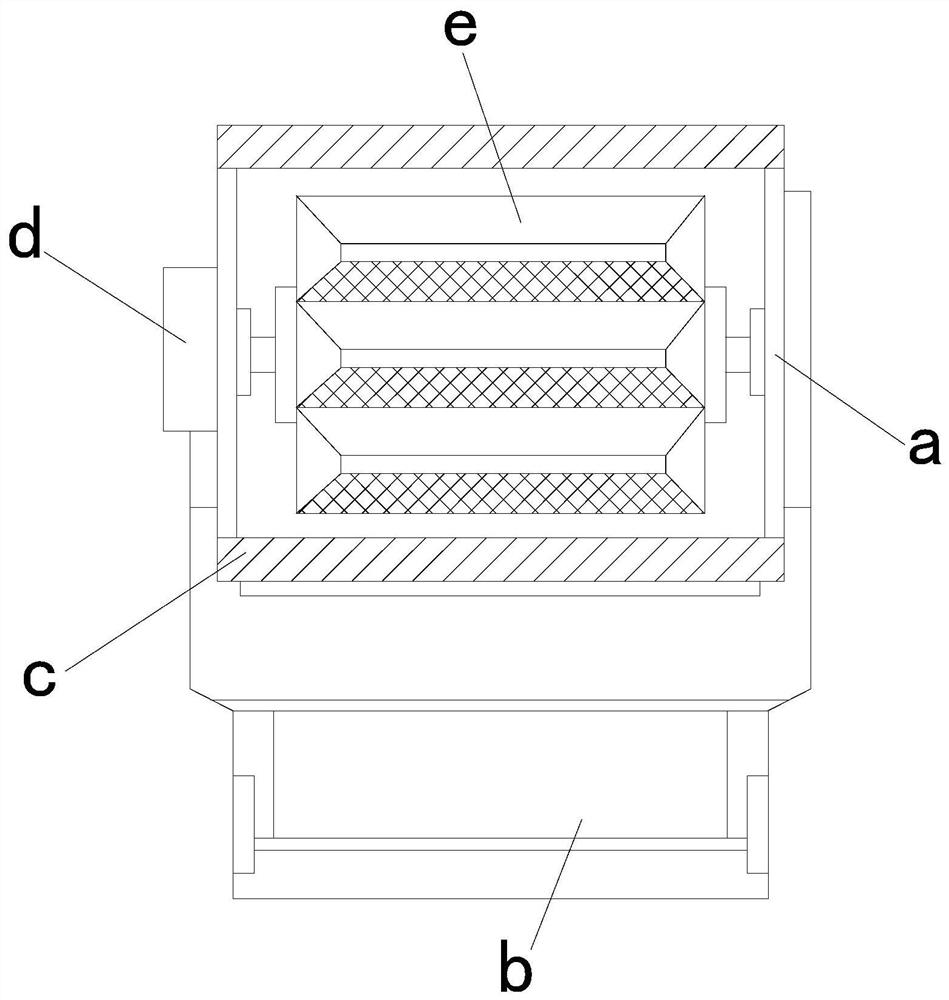

[0026] see Figure 1-Figure 4 , the present invention provides a smoke exhaust fan technical solution: its structure includes: a blower body 1, a power wheel set 2, a smoke exhaust pipe 3, a joint upper cylinder 4, and a smoke inlet pipe 5, and the smoke inlet pipe 5 is installed on the fan The front end of the blower body 1 is fastened with the blower body 1, and the side of the blower body 1 is provided with a power wheel set 2, and the power wheel set 2 is locked with the blower body 1, and the top of the blower body 1 is provided with There is a connection upper cylinder 4, the connection upper cylinder 4 is welded with the blower body 1, the upper end of the connection upper cylinder 4 is provided with a smoke exhaust pipe 3, the smoke exhaust pipe 3 is locked with the connection upper cylinder 4, and the air blower The cylinder body 1 includes a side guide plate device a, a collection bucket device b, an assembly frame c, a linkage shaft wheel d, and a fan guide wheel e....

no. 2 example

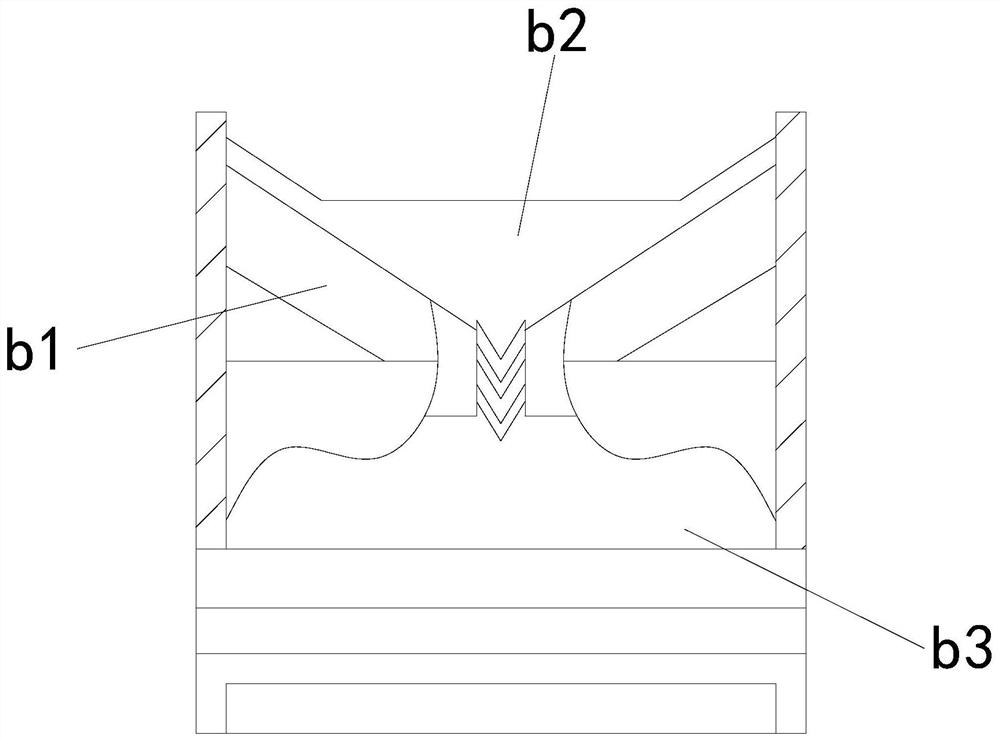

[0031] see Figure 5-Figure 6 , the present invention provides a smoke exhaust fan technical solution: its structure includes: the separation spreading device a1 includes a shaft scraping roller a11, a bearing frame a12, a concave dial a13, a scraper blade a14, and a fitting rod a15, the The concave dial a13 is installed on the end of the fitting rod a15 and welded with the fitting rod a15. The inner side of the fitting rod a15 is provided with a tooth scraper a14, and the scraper a14 is locked with the fitting rod a15. A bearing frame a12 is provided at the front end of the closing rod a15, and the bearing frame a12 is fastened to the laminating rod a15, and the inner side of the concave dial a13 is provided with a scraping roller a11 and is fastened to the scraping roller a11.

[0032] The shaft scraping roller a11 includes a built-in rod a111, an arc-shaped scraper a112, and a fixed head a113. The end of the a111 is locked with the built-in rod a111, and the scraping shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com