Cultivation plate cleaning machine

A washing machine and cultivation board technology, which is applied to dryers, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of time-consuming and labor-intensive manual cleaning, save labor costs, improve washing efficiency, and maintain cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

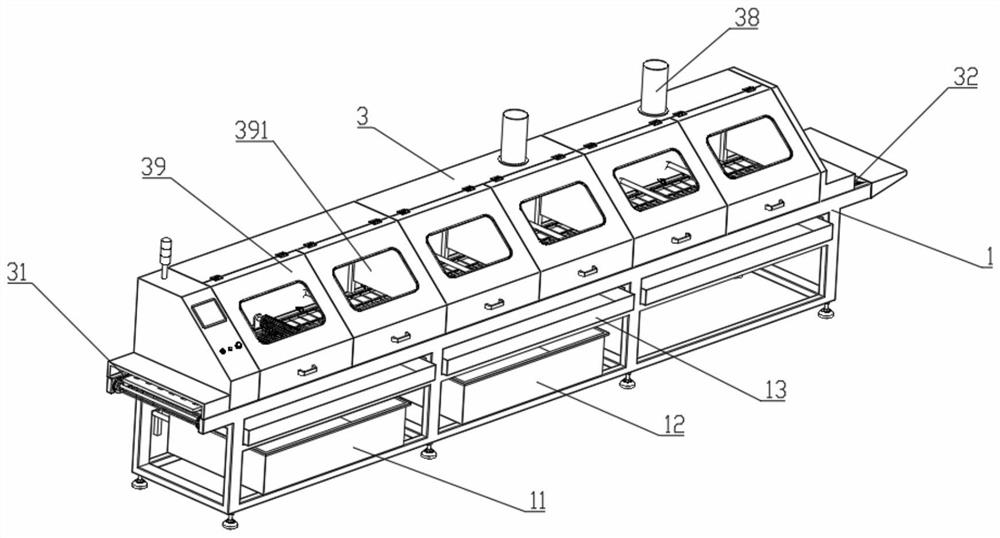

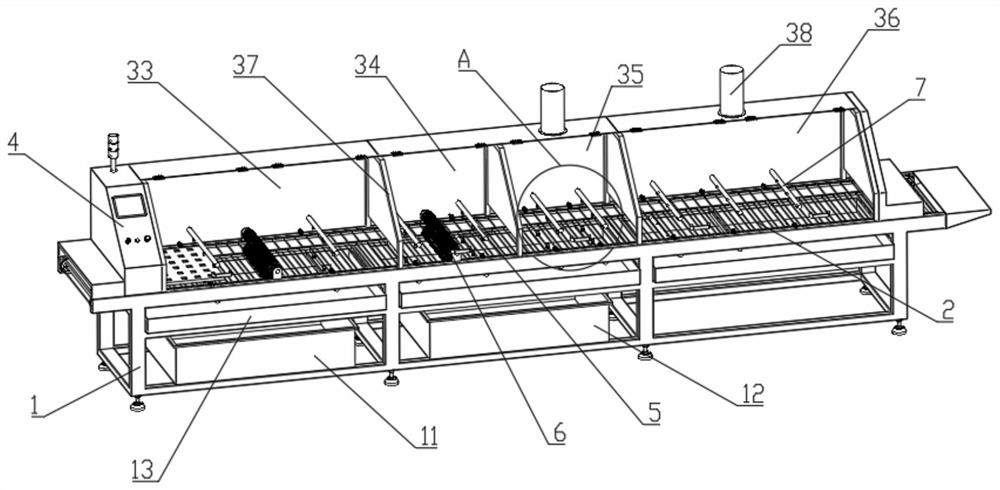

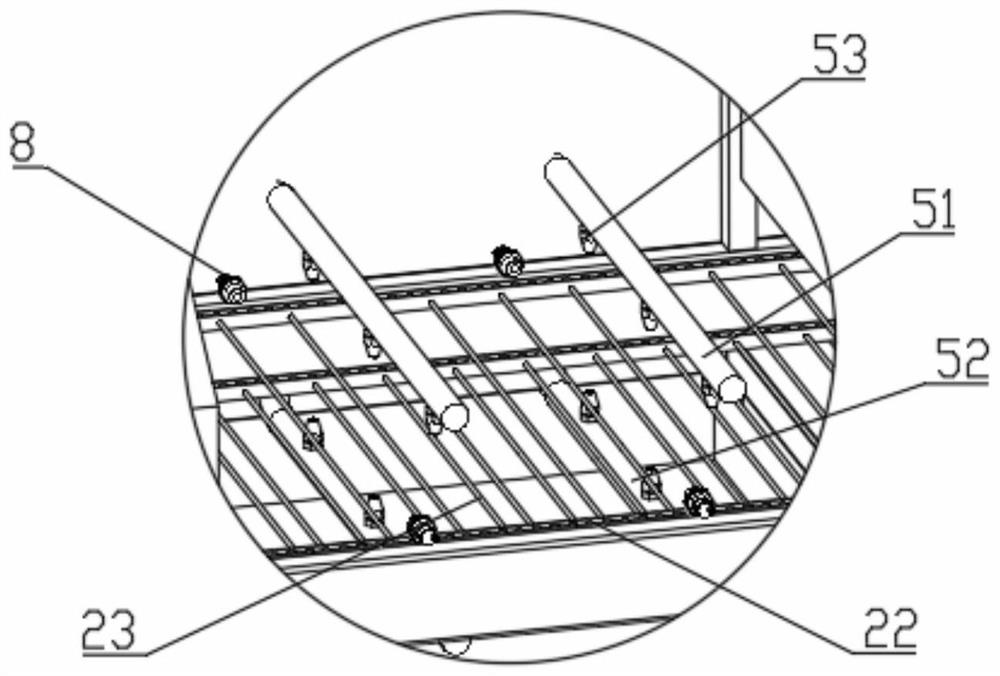

[0035] see Figure 1-7 , a cultivation board cleaning machine in this embodiment, comprising a support frame 1, a transmission track 2 and a cleaning cabinet 3, the cleaning cabinet 3 is fixed on the support frame 1, and the cleaning cabinet 3 is provided with cleaning inlets on both sides of the horizontal direction of the transmission track 2 31 and cleaning outlet 32, at least one cleaning chamber and drying chamber 36 are arranged in the cleaning cabinet 3, and the cleaning chamber and drying chamber 36 are arranged in sequence along the cleaning inlet 31 to the cleaning outlet 32, and the cleaning chamber and the cleaning inlet near the cleaning inlet 31 31 communicates, the cleaning outlet 32 communicates with the drying chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com