Ocean passenger ship structure segmented welding position automatic calculation method

A segmented welding and automatic calculation technology, applied to welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of long time consumption and high cost, and achieve the effect of improving rationality and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] A method for automatically calculating segmental welding positions of an ocean-going passenger ship structure, comprising the following steps:

[0043] S1. Expand and refine the assembly tree to the weld level;

[0044] S2. Classify and aggregate the weld nodes at all levels on the assembly tree;

[0045] S3. Determine the weld seam welding stage after classification aggregation;

[0046] S4. Determine the subassembly construction direction;

[0047] S5. Determine when and in what posture each part should be assembled, that is, under the condition of known assembly tree, realize the simulated assembly process from part to segment;

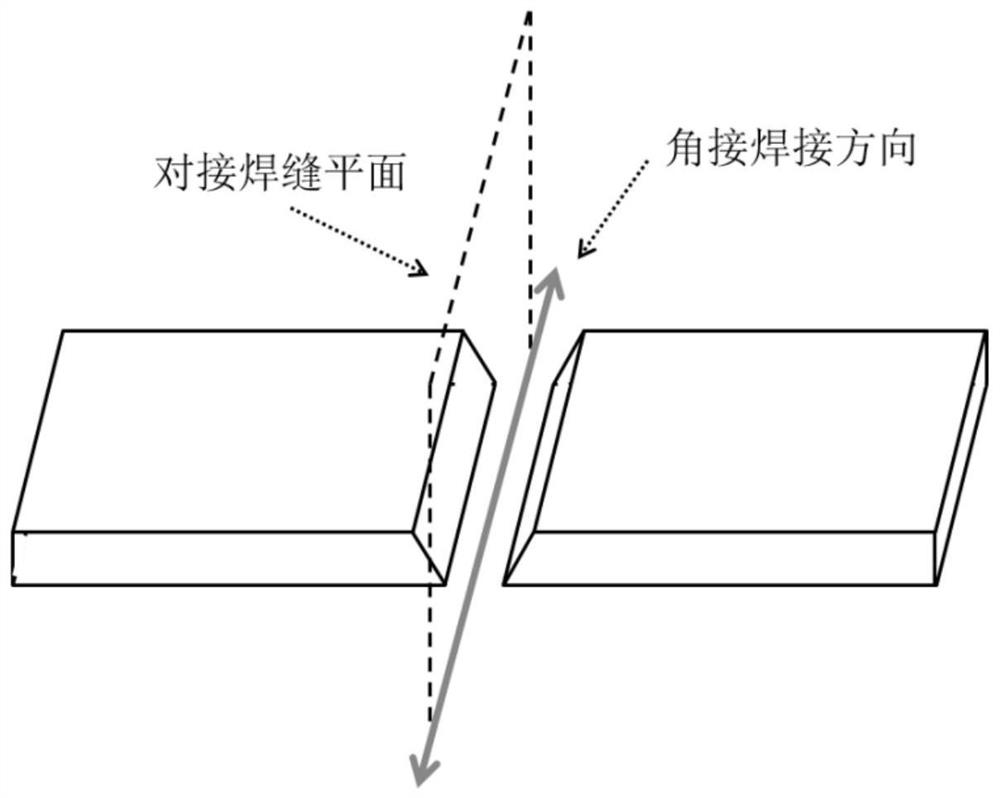

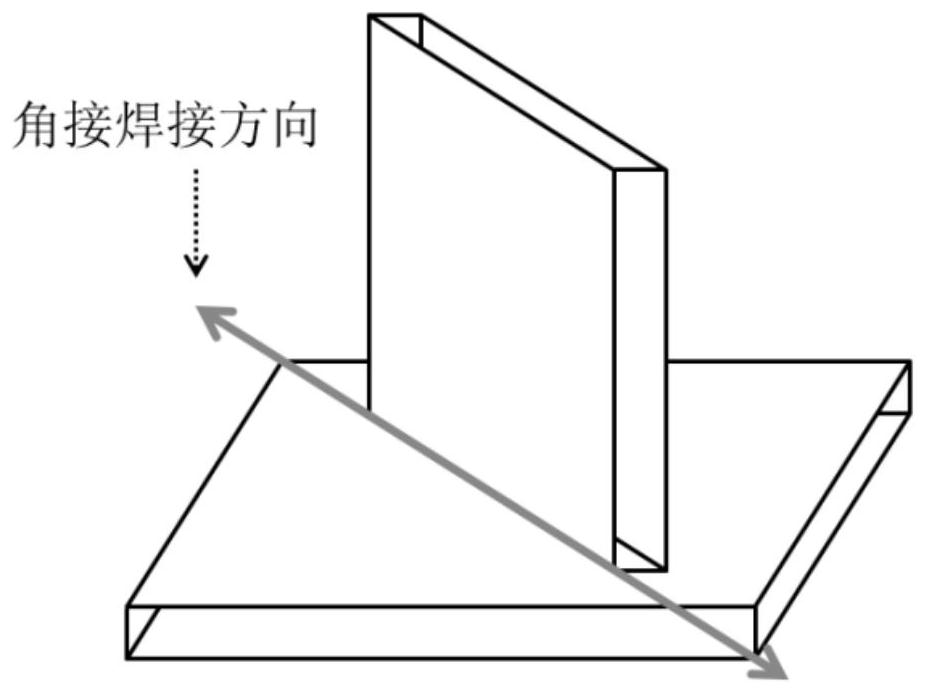

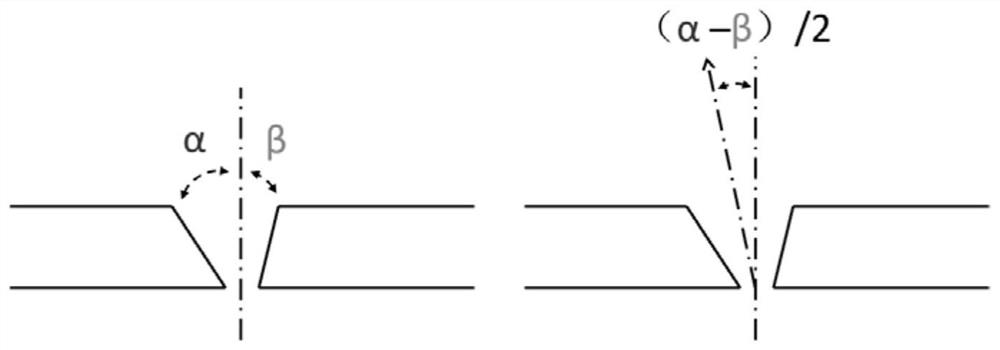

[0048] S6. According to the assembly construction posture, the normal vector direction of the weld plane is adjusted from the original orientation of the 3D model to the orientation of the assembly construction;

[0049] S7. Determine the spatial orientation of the welding axis, that is, the normal vector of the welding surface;

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com