Deep embossing gilding press efficient in production

An embossed bronzing machine and deep-pressing technology, applied in the field of deep embossing bronzing machine, can solve the problems of reducing the working efficiency of staff, feeling of fatigue, inconvenient height of the table top, etc., to improve the quality of bronzing, reduce the feeling of fatigue, and improve the practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

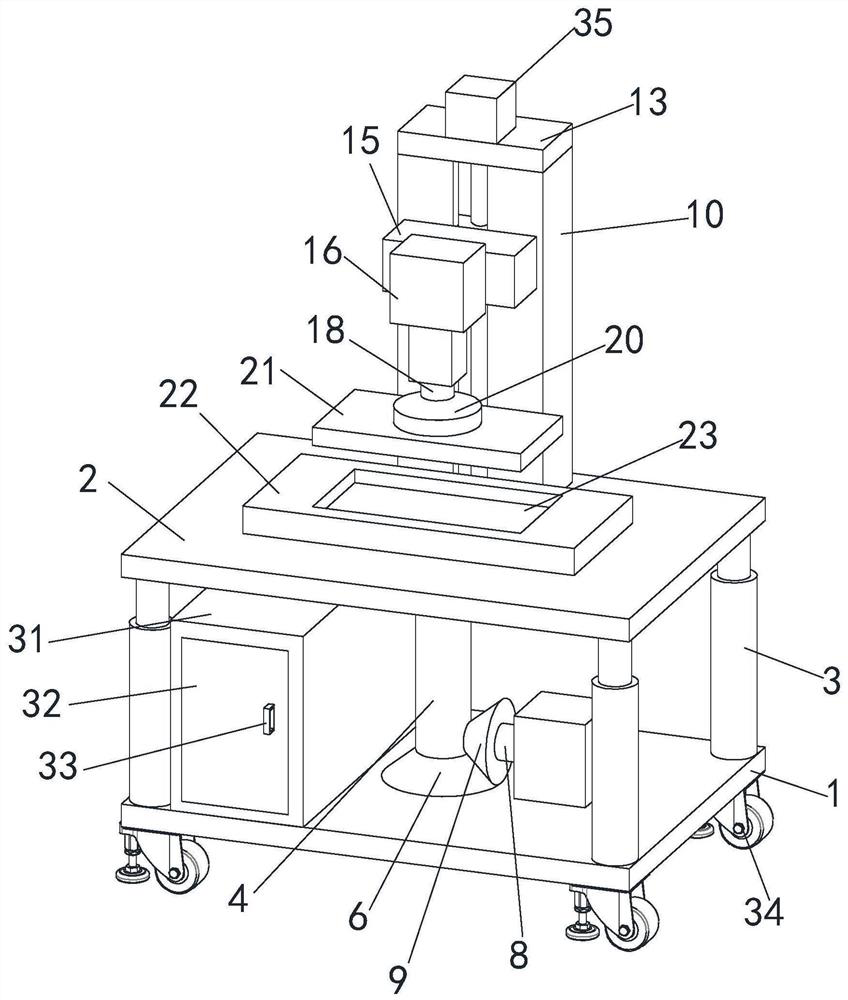

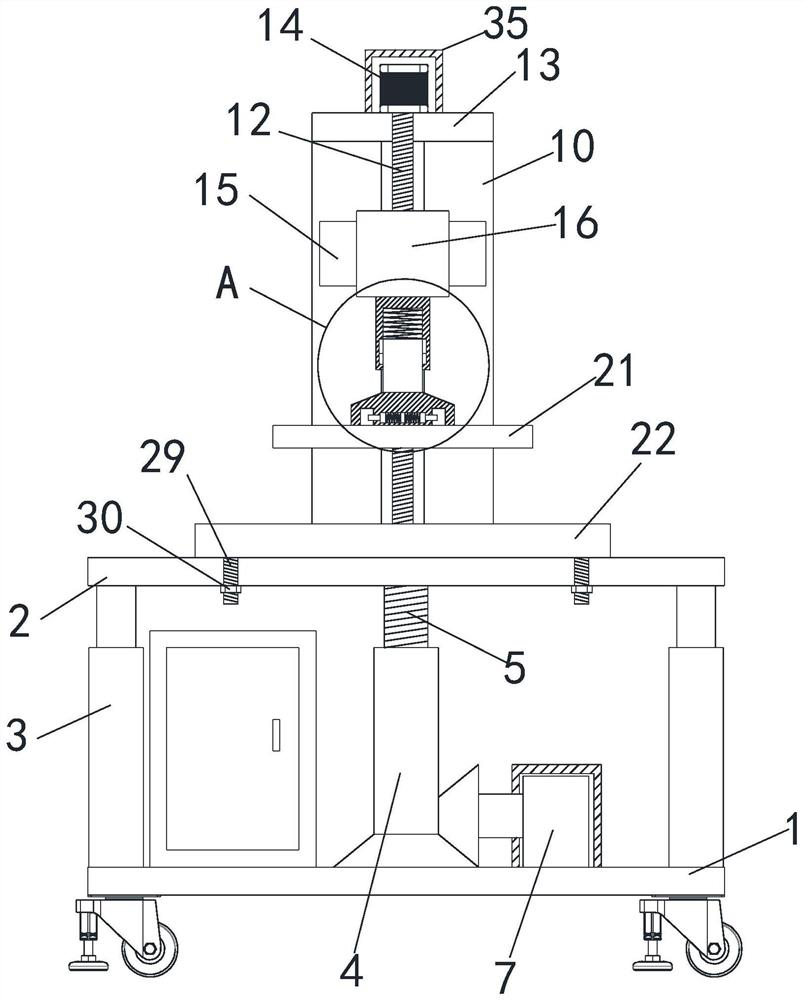

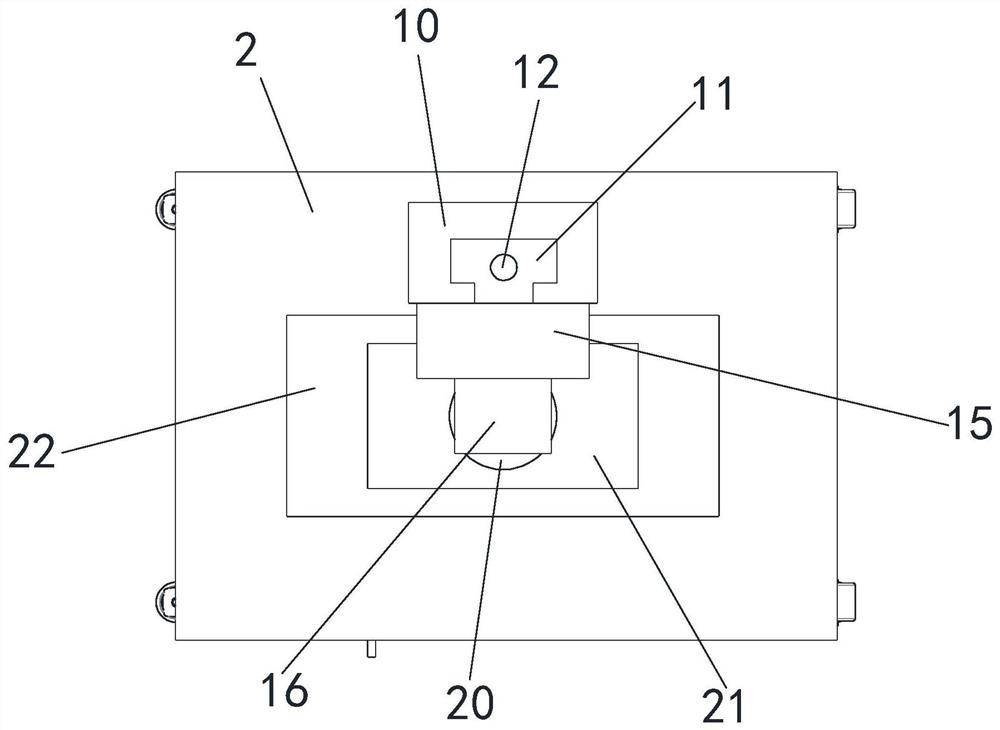

[0026] see Figure 1-4 , a high-efficiency deep embossing hot stamping machine, including a base plate 1 and a table plate 2, the four corners of the top of the base plate 1 are fixedly connected with telescopic rods 3, the bottom end of the table plate 2 is connected to the top of four telescopic rods 3 Fixedly connected, the middle position of the top of the bottom plate 1 is rotatably connected with a coil 4, the internal thread of the coil 4 is connected with a first screw 5, the top of the first screw 5 is fixedly connected with the bottom of the table 2, and the screw 4 The bottom of the outer side is provided with a first bevel gear 6, the right side of the top of the bottom plate 1 is fixedly connected with a first motor 7, the output end of the first motor 7 is fixedly connected with a rotating shaft 8, and the left end of the rotating shaft 8 is fixedly connected with a second motor. Bevel gear 9, the second bevel gear 9 meshes with the first bevel gear, the rear sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com