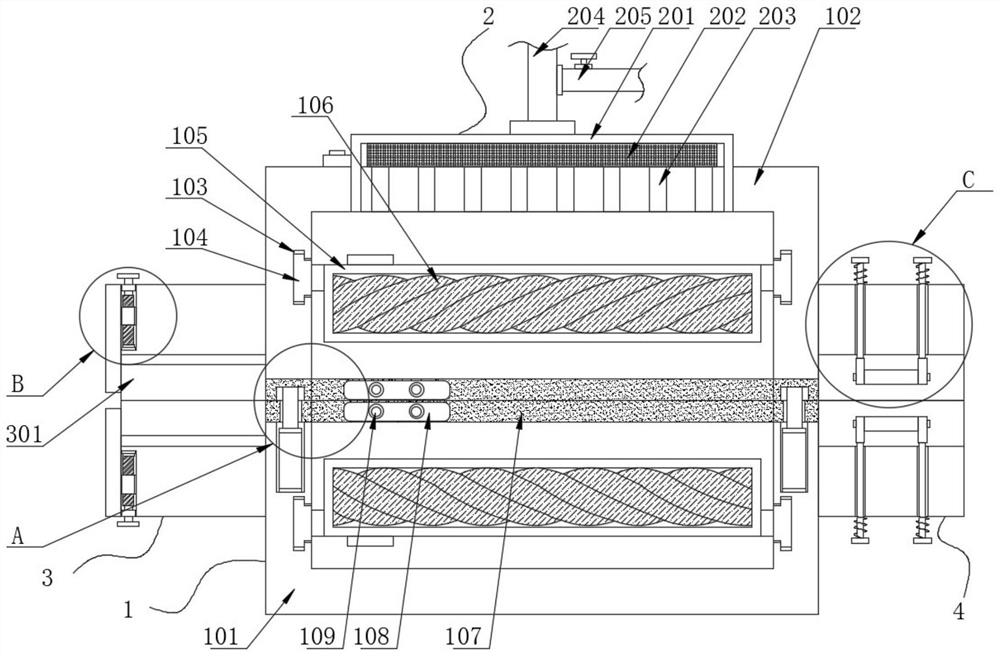

Efficient textile wool fabric dust removal device

A technology for dust removal device and wool fabric, which is applied in textile and paper making, high-pressure cleaning, dry gas arrangement, etc., can solve the problems of drifting into the placement workshop, affecting the overall aesthetics, and bonding the surface of wool fabrics, etc., so as to reduce the difficulty of dust removal. , The effect of improving dust removal efficiency and reducing the frequency of shutdown and dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

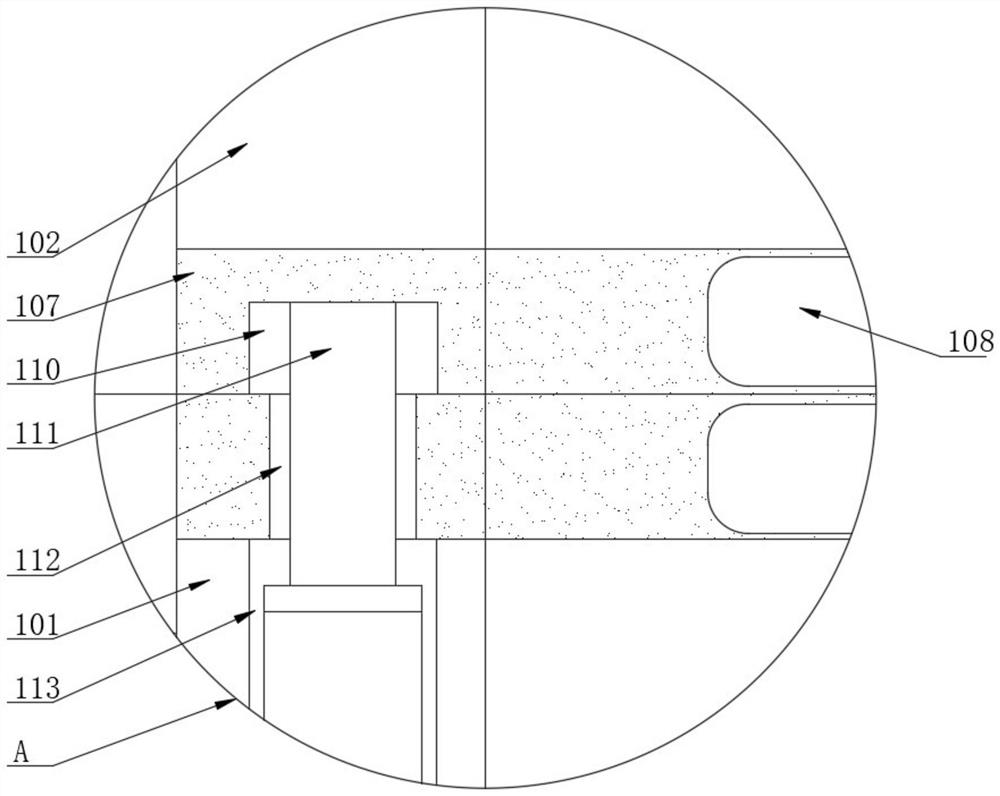

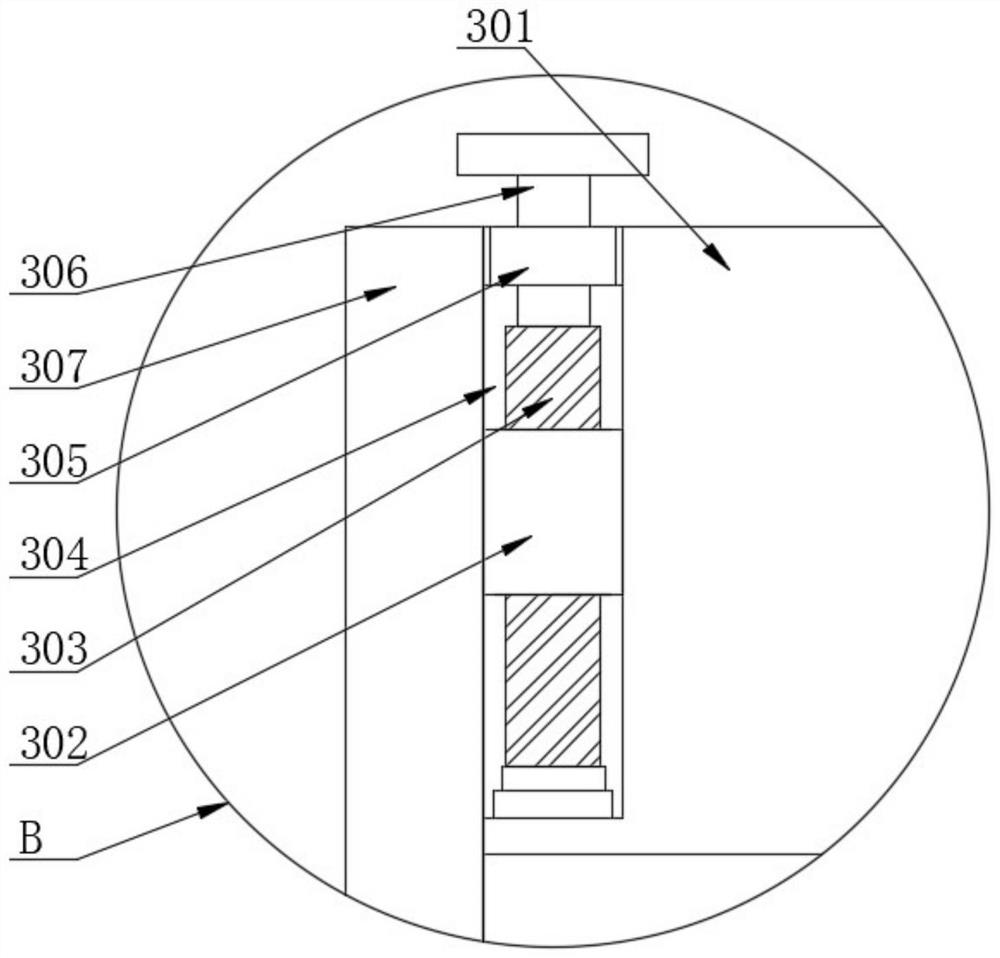

[0054] The specific embodiment is: when the wool fabric enters the inner cavity of the upper housing 102 through the windshield 301 on one side, the windshield 301 can slide in the second chute 304 through the threaded cap 302 on one side, and the rotating shaft is driven by twisting the handle. 306 and the threaded cap 302 move, and the threaded cap 302 moves to drive the threaded cap 302 to pull the windshield 307 to move downward, and the windshield 307 moves downward to fit the upper and lower sides of the woolen fabric, thereby reducing the blown wind on one side. The moving air flows out, effectively reducing dust splashing, and the wool fabric can be pasted by the ion bar 407 of the electric shock mechanism on the other side after dust removal, and the ion bar 407 can slide in the sliding sleeve 402 through the clamp blocks 406 and the sliding rod 403 on both sides , the sliding bar 403 slides to drive the top block 405 to squeeze the spring 404, the spring 404 can absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com