A wall-climbing welding robot

A welding robot and wall-climbing technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of single function of welding robot, avoid welding seam defects, save manpower and time, and facilitate installation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

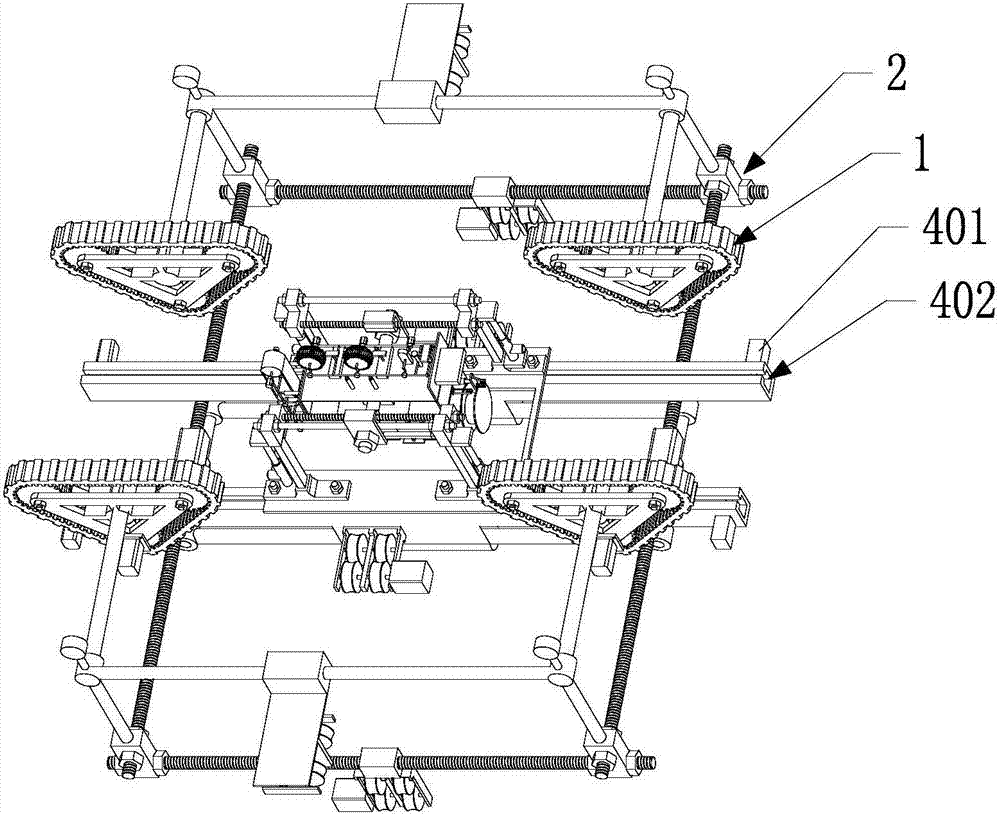

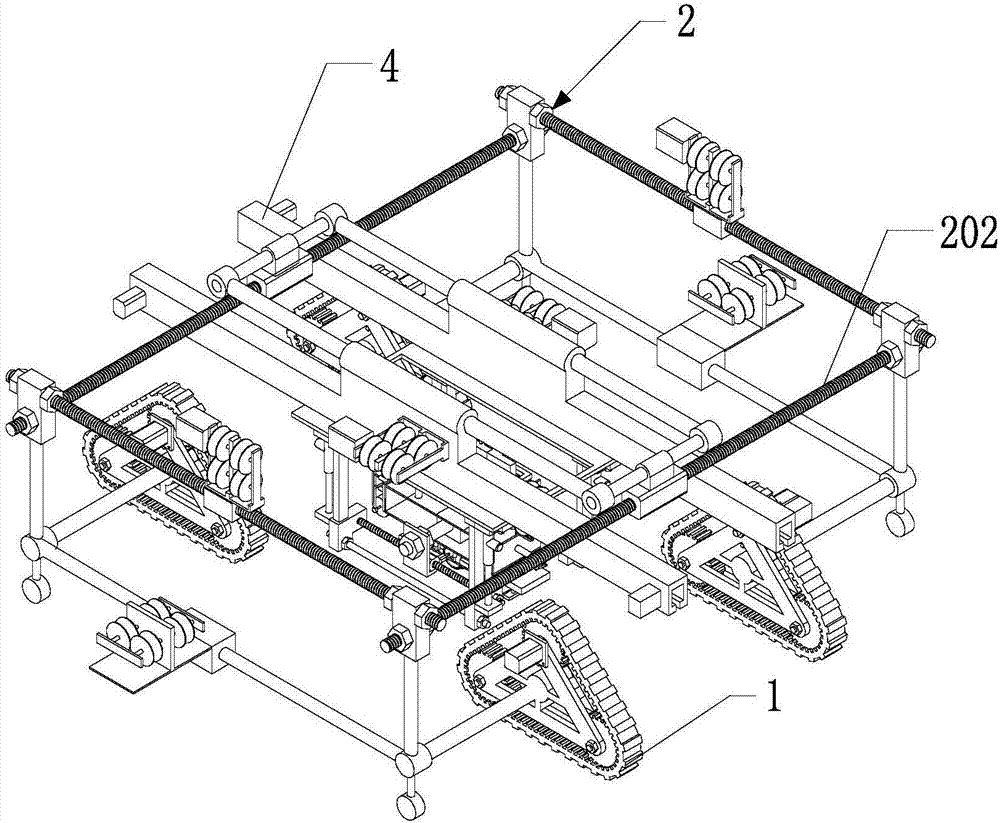

[0050] Combine below Figure 1 to Figure 12 The present invention will be described in detail.

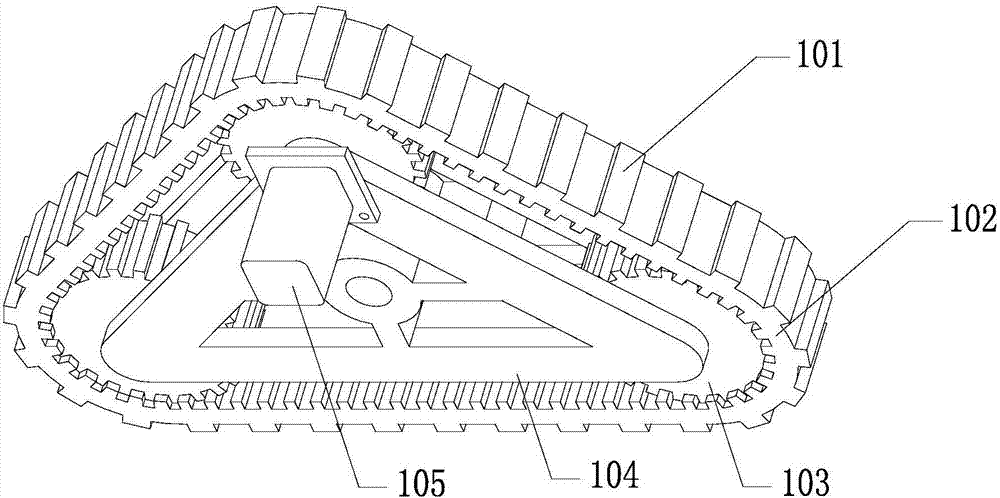

[0051] A wall-climbing welding robot includes a frame 2 with a walking mechanism, the walking mechanism includes several supporting rods extending downward, and universal wheels 201 are installed on the lower ends of the supporting rods; Cross bar, wall climbing wheel 1 is installed on the cross bar, described wall climbing wheel 1 comprises triangular wall climbing frame 104, and climbing wall frame 104 is provided with the bearing that is used to install cross bar; Stepper motor 105 and the synchronous pulley 103 driven by the first stepping motor 105, the synchronous belt 102 that is suitable for the synchronous pulley 103 is installed on the synchronous belt pulley 103, the outside of synchronous belt 102 is provided with a plurality of electromagnetic sucker 101.

[0052] The frame 2 includes two first guide rails 202 distributed in parallel, on which two first guide rails 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com