A magnetic levitation drive device

A driving device and maglev technology, which are applied in electromechanical devices, holding devices using magnetic attraction or thrust, and electric components, etc., can solve the problems of inapplicability in the field of precision direct motion, large deformation of the mobile table, and reduce the processing cost and difficulty. , Easy to install and adjust, reduce the effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, and do not have any limiting effect on it.

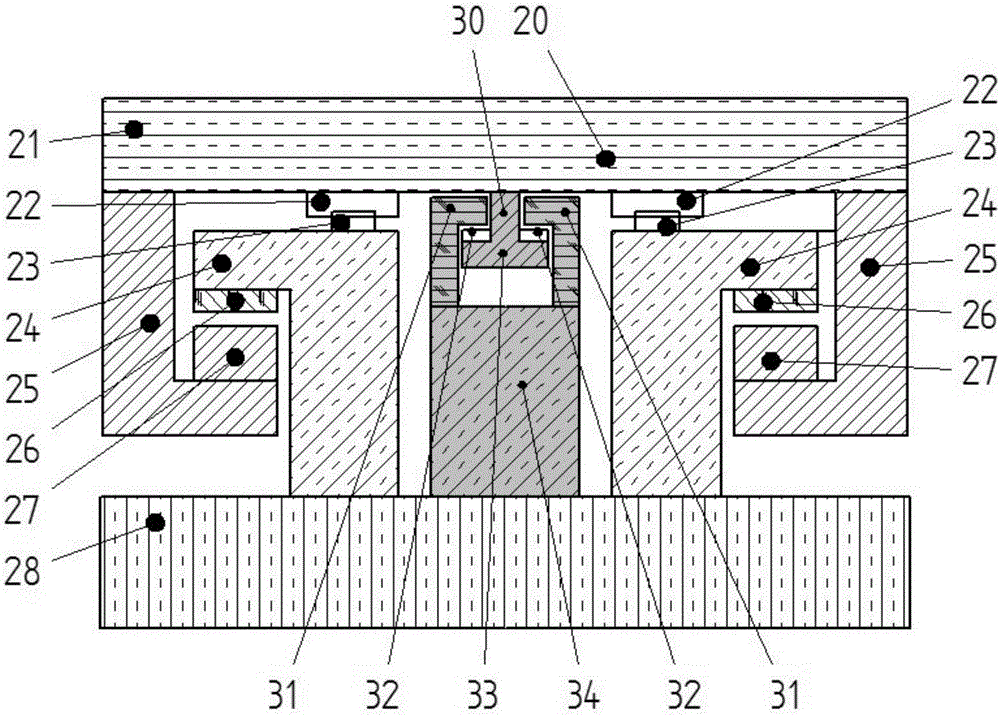

[0037] figure 1 The reference signs in are: main maglev module 20, moving workpiece table 21, slider 22, guide rail 23, main support 24, maglev support body 25, linear motor permanent magnet stator 26, linear motor mover 27, base 28, A secondary maglev module 30 , a secondary support 31 , a permanent magnet 32 , a secondary maglev support 33 , and a secondary base 34 .

[0038] The magnetic levitation driving device in this embodiment is as figure 1 As shown, it includes a main maglev module 20 and an auxiliary maglev module 30 .

[0039] The main maglev module 20 includes a base 28, a moving workpiece table 21, a slider 22, a guide rail 23, a main support 24, and a maglev unit. The magl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com