Frictional resistance increasing method based on interface mechanical effect

A technology of frictional resistance and interface mechanics, applied in the direction of hydraulic resistance brakes, brake components, brake types, etc., can solve problems such as increasing frictional resistance, and achieve the effect of increasing frictional resistance, simple method and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

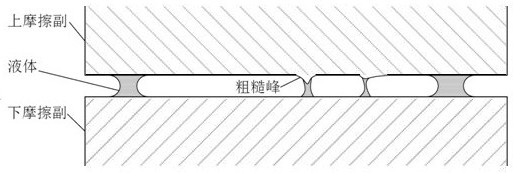

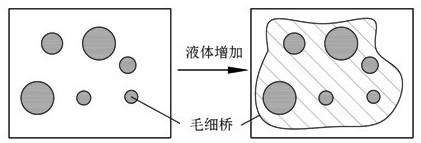

[0021] The wall thickness is 5mm, the length is 40mm, and the width is 20mm. The plexiglass is used as the friction pair. The surface roughness Ra<0.008μm, the load is 1㎏, and the test friction resistance at room temperature is about 1.5N. Drop 1 to 2 μL of deionized water on the surface of the friction pair, and the estimated thickness of the liquid film is about 5 μm. Under the same conditions, the friction resistance is 14±2N, and during the test time of 200s, the friction resistance is relatively stable, and the friction resistance is increased by nearly 10 times. It is shown that the interfacial mechanical effect caused by a small amount of liquid between the surfaces of the friction pairs can greatly improve the relative resistance between the friction pairs. In addition, when the volume of deionized water between the friction pairs increased to 5 to 6 μL, the frictional resistance decreased to 3±1 N, indicating that the frictional resistance could be controlled by incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com