Built-in rotary encoder for detecting rotation speed

A technology for rotary encoders and detection of rotation, applied in the field of rotary encoders, can solve the problems of rotary encoders lacking auxiliary lubrication of rotating structures, affecting the use of devices, and good anti-interference performance, so as to increase smoothness and stability, and facilitate work , add protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

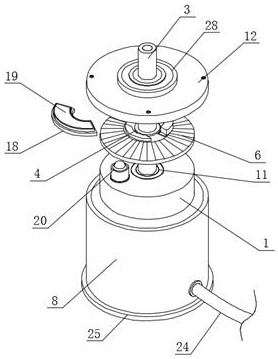

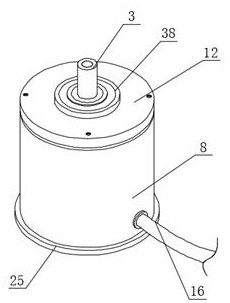

[0039] see figure 1 , Figure 7 and Figure 8 , an embodiment provided by the present invention, a rotary encoder with a built-in detection of rotation speed, including a connection base 1, a code disc 6 and a speed measurement module 7, a light source assembly 20 is provided on one side of the top of the connection base 1, and the connection base 1 The base 2 is installed at the bottom of the base 2, the outer surface of the base 2 is provided with a power cord assembly 24, the bottom of the protective tube 8 is provided with a non-slip base 25, the top of the base 2 is provided with a rotating shaft 3, and the middle part of the outer surface of the rotating shaft 3 is connected with a connecting shaft 5 , the middle part of the outer surface of the connecting shaft 5 is equipped with a code disc 6, one side of the bottom of the code disc 6 is fitted with a photoelectric transmitting unit 22, and the other side of the bottom of the code disc 6 is fitted with a photoelectric...

Embodiment 2

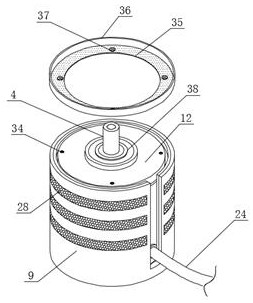

[0042] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , an embodiment provided by the present invention, a rotary encoder with a built-in detection of rotation speed, including a protective tube 8, a limit sleeve 9 and an extrusion block 32, the bottom of the base 2 is connected to the protective tube 8, and the base 2 is located at Inside the protective tube 8, the bottom of the protective tube 8 is connected to the limiting sleeve 9, the bottom of the inner wall of the limiting sleeve 9 is provided with a connecting groove 29, the inner wall of the connecting groove 29 is provided with a limiting tube 30, and the front end of the limiting tube 30 Plug the limit rod 31, the front end of the limit rod 31 is provided with an extruding block 32, the front end of the extruding block 32 is provided with an insulating pad 33, and one side of the outer surface of the limit sleeve 9 is provided with a snap-in groove 26, The outer surface of the limitin...

Embodiment 3

[0045] see figure 1 , Figure 6 , Figure 7 and Figure 8 , an embodiment provided by the present invention, a rotary encoder with a built-in detection of rotation speed, including an upper bearing 4, a positioning shaft 11 and a lower bearing 21, the top of the connecting seat 1 is provided with an upper bearing 4, and the upper bearing 4 The top is connected to the bottom of the outer surface of the rotating shaft 3, and the top of the outer surface of the rotating shaft 3 is provided with a positioning shaft 11. The outer surface of the positioning shaft 11 is connected with a front cover 12, and the bottom of the front cover 12 is provided with a limiting groove 13. The inner top wall is connected with a positioning ring 14, the bottom thread of the positioning ring 14 is connected with a positioning bolt 15, the inner wall of the positioning ring 14 is connected with a circuit board assembly 16, the top of the front cover 12 is provided with a flange 38, and the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com