Oil suction pipe support

A technology of oil suction pipe and clamping pipe, which is applied in the direction of pipe bracket, lubricant conduit device, pipe/pipe joint/pipe fitting, etc., which can solve the problems of high manufacturing cost, inconvenient use, inconvenient adjustment of fixed position, etc., and reduce assembly Effects of Difficulty and Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

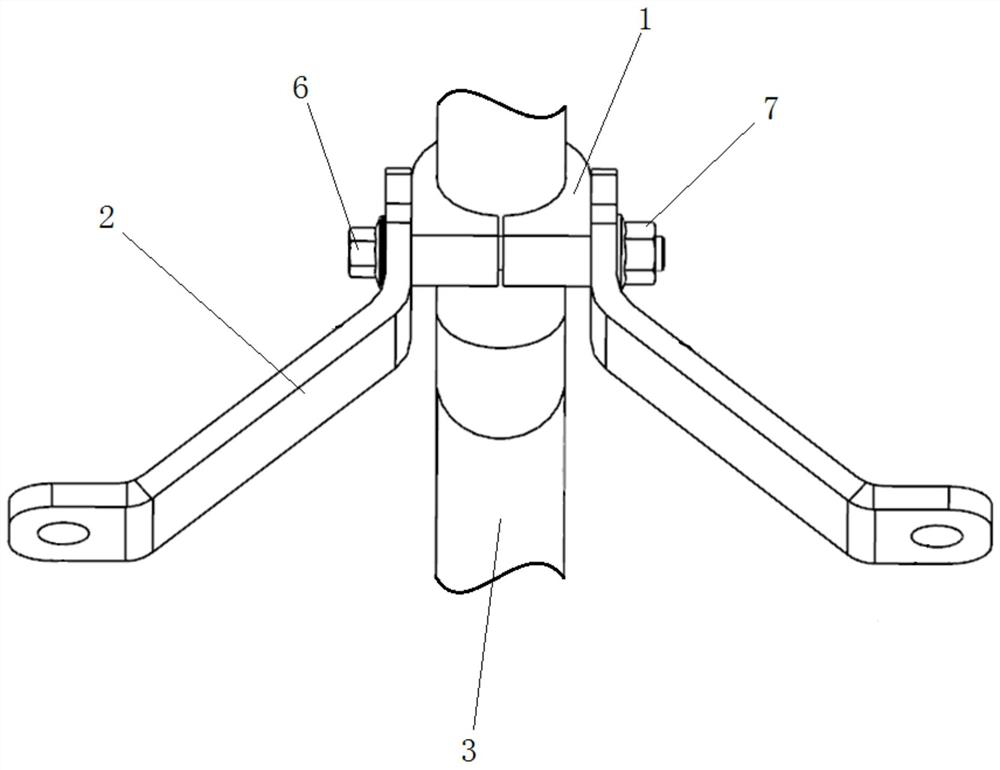

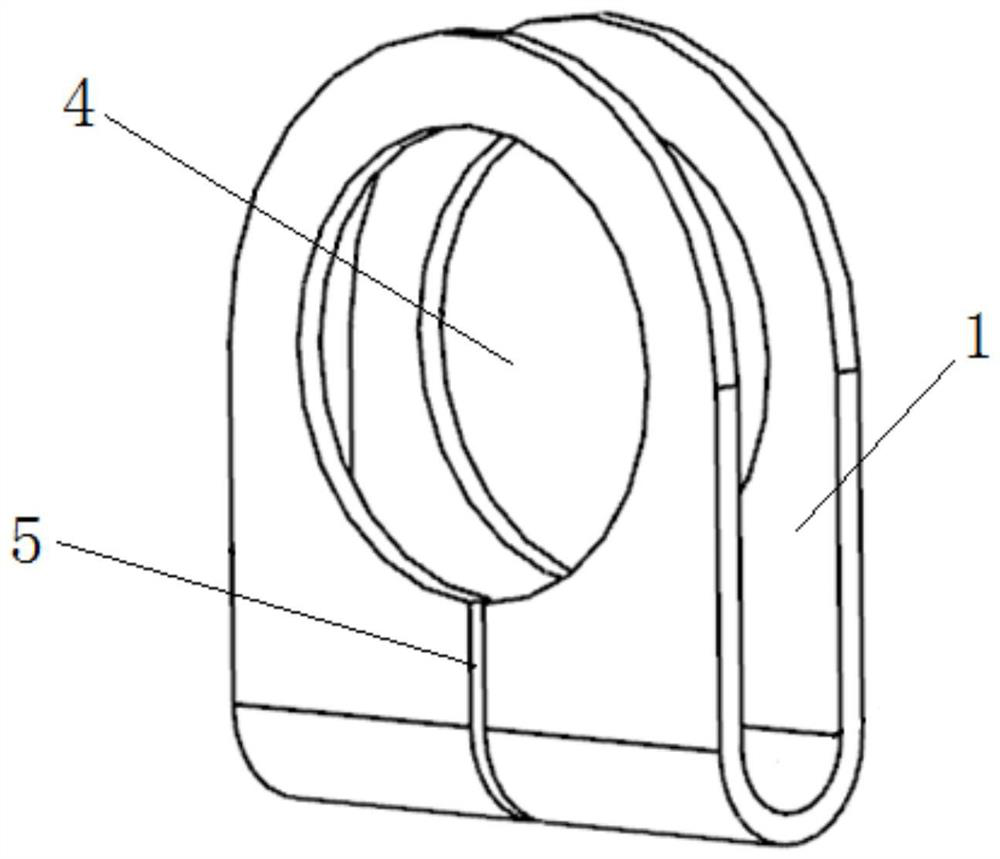

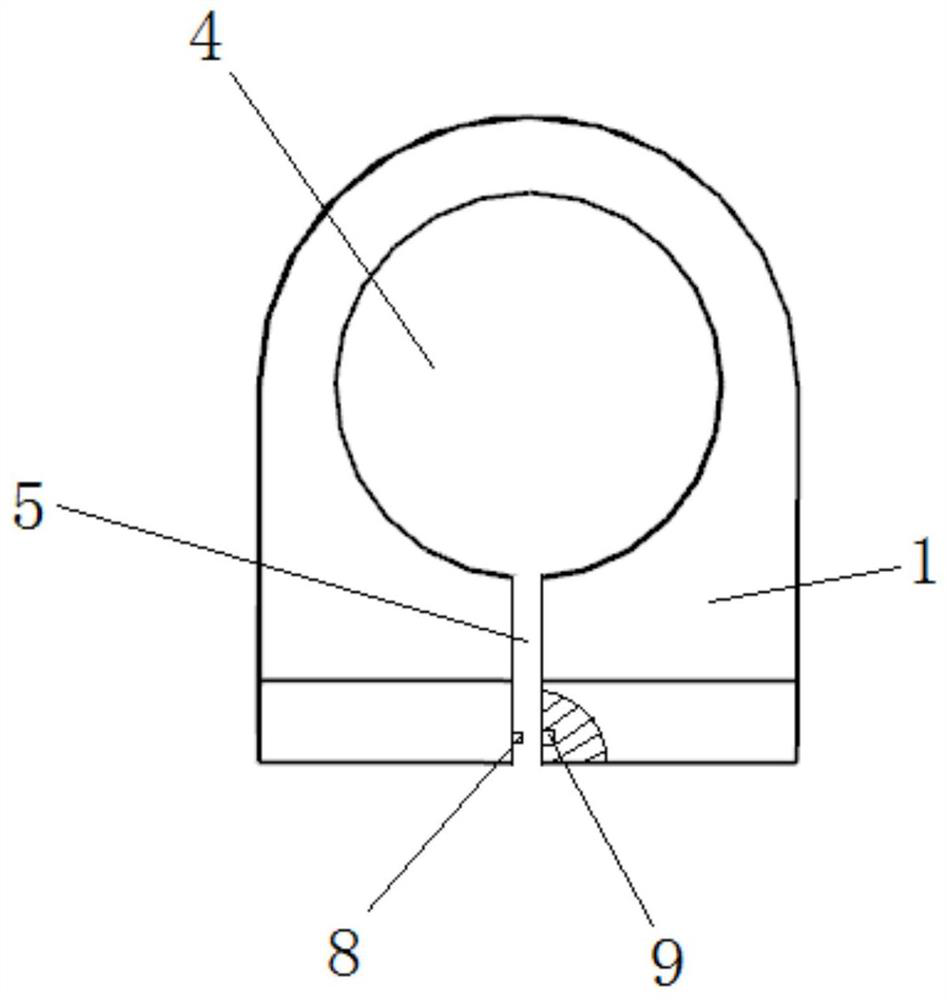

[0020] refer to Figure 1-4 , an oil suction pipe support of the present invention, comprising a U-shaped pipe clamp 1 and two support plates 2, and an insertion hole 4 for installing an oil suction pipe 3 is provided at the opening end of the U-shaped pipe clamp 1, and the insertion hole 4 It runs through the two side plates of the U-shaped pipe clamp 1, and the insertion hole 4 is closely matched with the oil suction pipe 3, that is, the U-shaped pipe clamp 1 is movably sleeved on the oil suction pipe 3, and the closed end of the U-shaped pipe clamp 1 is provided with The gap groove 5 communicated with the socket hole 4 makes the closed end of the U-shaped pipe clamp 1 divided into two parts, and the two support plates 2 are respectively located at the two ends of the U-shaped clamp pipe 1, and the two support plates 2 pass through through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com