Conductive substrate and manufacturing method thereof

A kind of conductive substrate, technology of manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

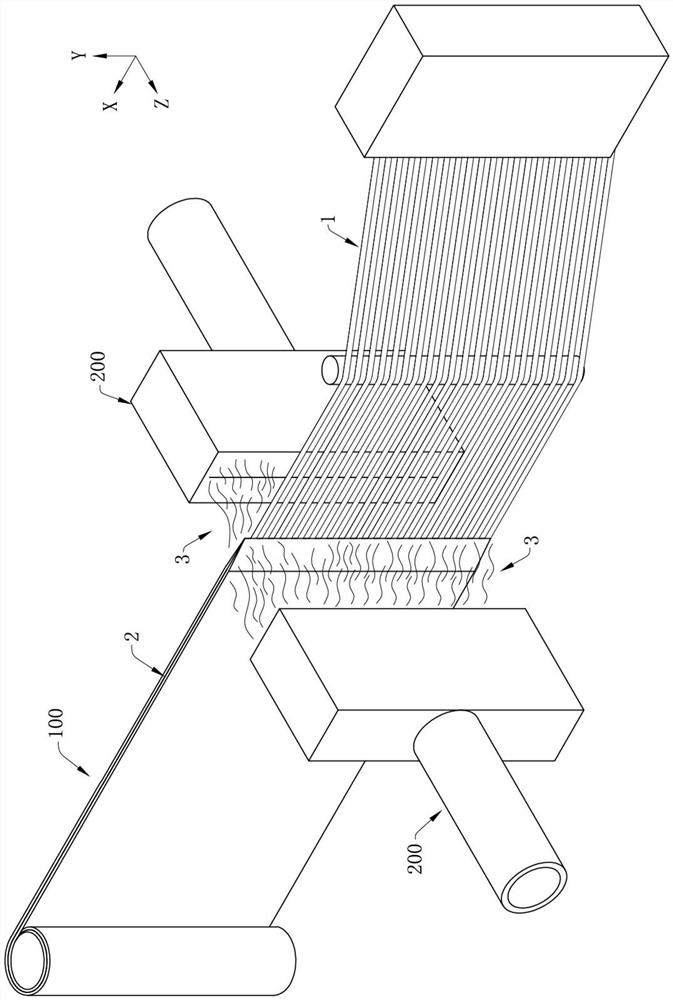

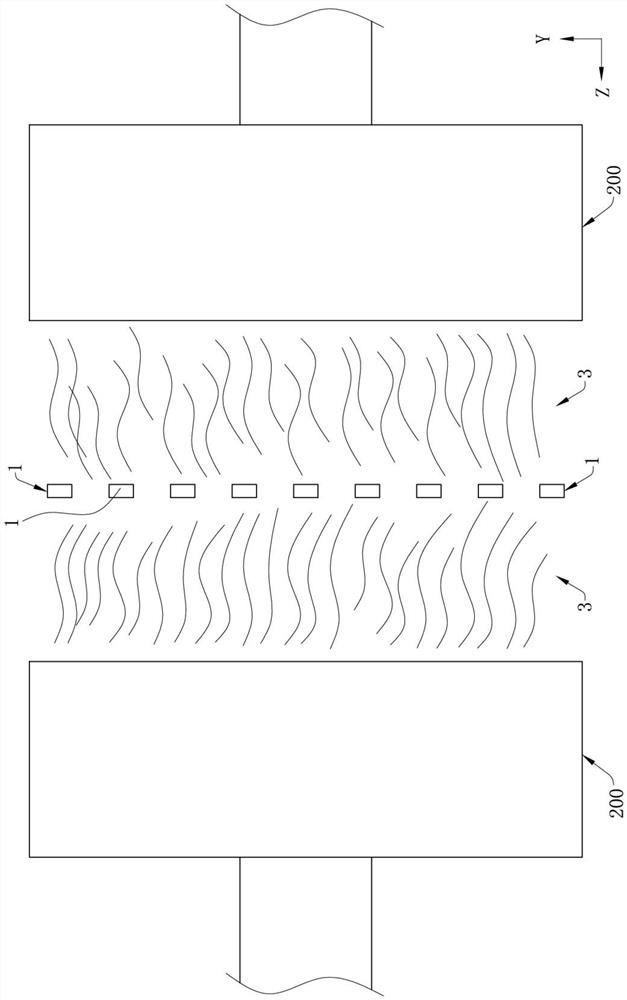

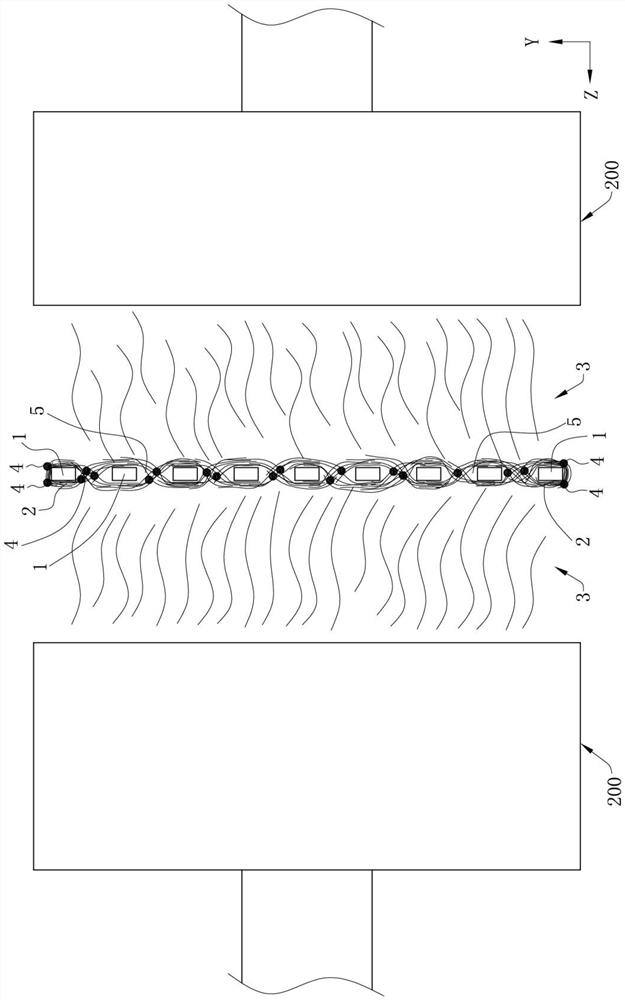

[0041] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

[0042]The so-called conductive substrate 100 in the present invention includes flexible flat cable (FFC), flexible circuit board (FPC), rigid printed circuit board (PCB) and other plate-shaped electronic equipment with a certain length of conductive circuit, which includes at least one plane A plurality of conductive elements 1 arranged side by side, such as copper wires, etched copper layers, etc., serve as a circuit for transmitting electrical signals, wherein two adjacent conductive elements 1 have a gap. The conductive substrate 100 also includes an insulating layer 2 covering a plurality of the conductive elements 1, the insulating layer 2 is composed of a large number of insulating fibers 3 stacked randomly, and the insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com