Optimization method of isolation column super junction structure

An optimization method, a technique for isolating columns, used in design optimization/simulation, constraint-based CAD, calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

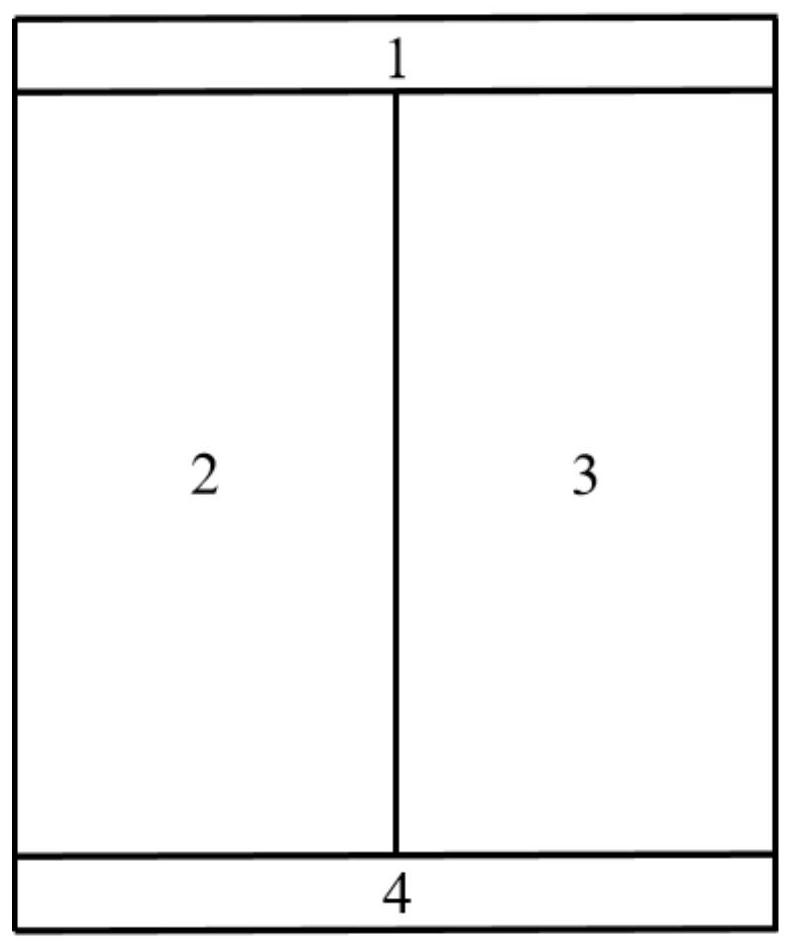

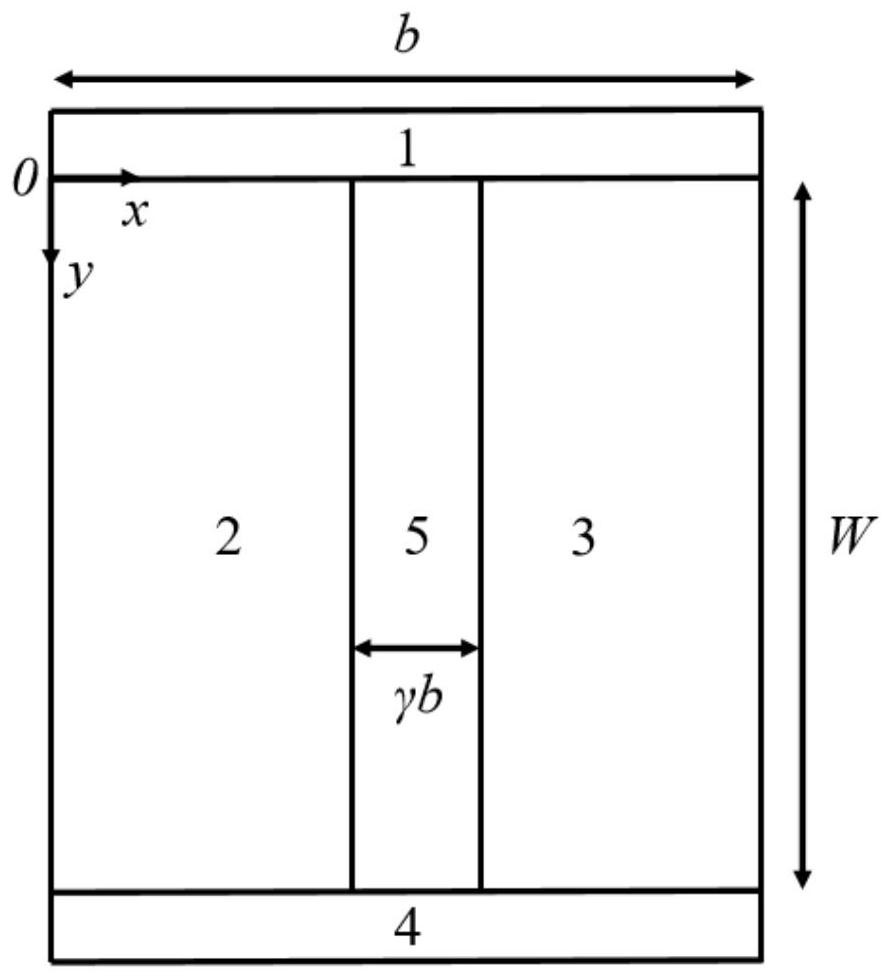

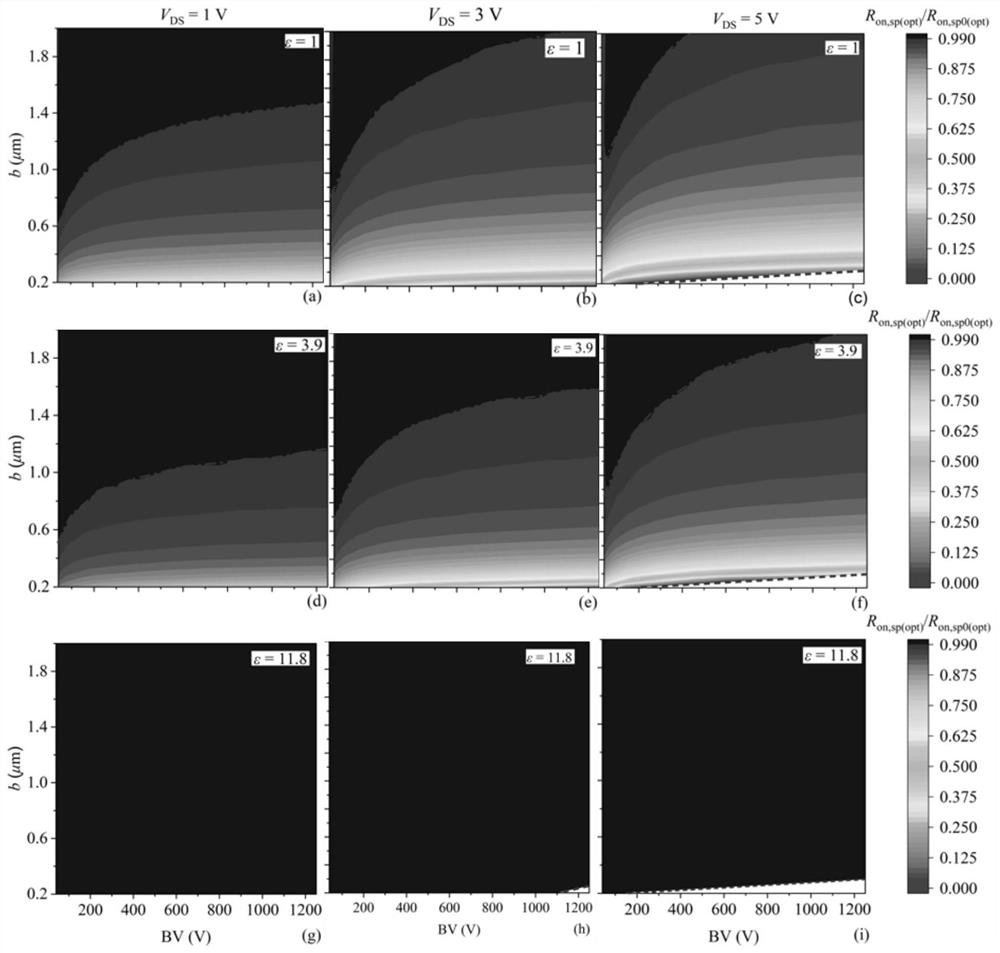

[0047] A method for optimizing an isolation column superjunction structure, comprising the following steps:

[0048] Step 1. Build the objective function:

[0049]

[0050] where R on,sp (T) represents the specific on-resistance at temperature T, W represents the thickness of the n-column and p-column in the superjunction structure, q represents the unit charge, μ n (T) represents the electron mobility at temperature T (the subscript n represents electrons), N represents the doping concentration of n-column and p-column (the doping concentration of n-column and p-column is the same); n(T) represents the electron concentration at temperature T, A(T) is a parameter related to temperature T, which can be obtained by solving the following equation:

[0051]

[0052] where c(T) is an exponential function related to temperature, c(T)=exp{-1.08+4.73×10 -4 ×[9×10 4 / 936-T 2 / (T+636)] / 0.0258}, γ represents the ratio between the width of the isolation pillar 5 and the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com