Large casting thermal shape righting method

A technology of large-scale castings and thermal correction, which is applied in heat treatment furnaces, furnace types, heat treatment equipment, etc., can solve problems that affect the accuracy of casting dimensions, casting deformation, springback deformation, etc., to improve correction accuracy and product qualification rate, improve The effect of correction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

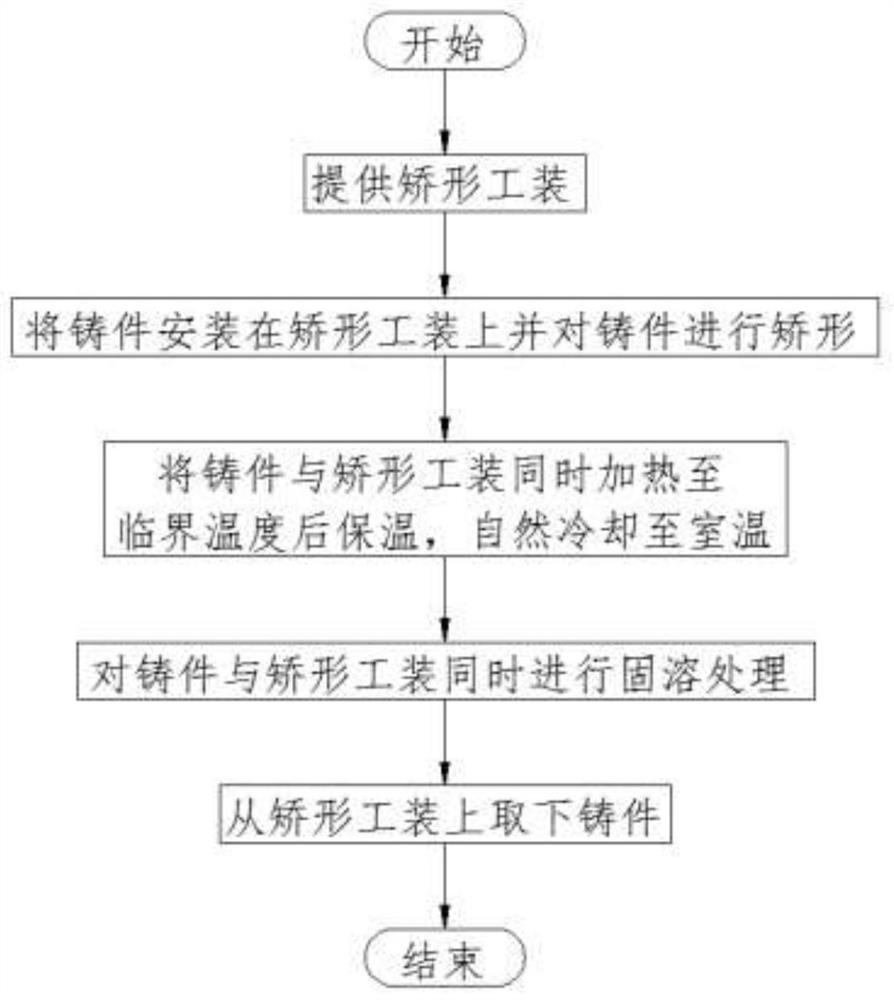

[0026] Such as figure 1 , figure 2 As shown, the present invention provides a kind of large-scale casting thermal correction method, comprises the following steps:

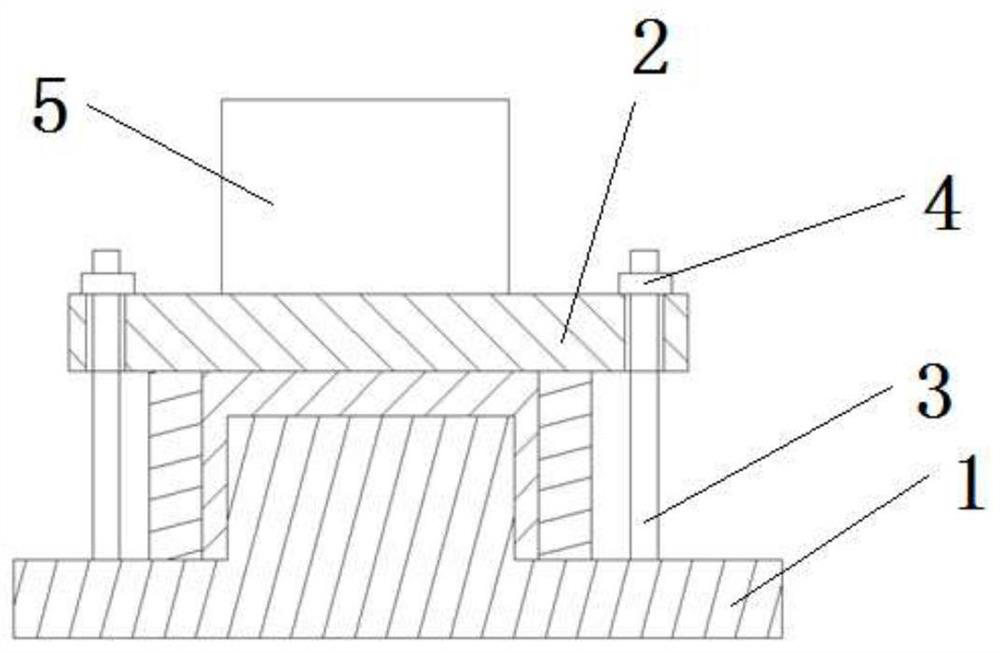

[0027] Step 1: Provide orthopedic tooling, which includes a base 1, a pressure plate 2, a support screw 3 and a lock nut 4, one end of the support screw 3 is fixedly connected to the base 1, and the other end of the support screw 3 passes through the pressure plate 2 and the lock nut 4 screw connections;

[0028] Step 2: Clamp the casting between the base 1 and the pressure plate 2, apply force to the casting by screwing the locking nut 4, and correct the casting through the force;

[0029] Step 3: Perform solid solution treatment at the same time on the rectified casting and the orthodontic tooling in step 2, that is, after heating the casting and the orthodontic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com