Vertical lathe for distance ring machining and machining process of distance ring

A technology of vertical lathes and distance rings, applied in metal processing equipment, metal processing machinery parts, turning equipment, etc., can solve problems such as low precision and trouble, and achieve the effects of improving clamping precision, reducing waste, and facilitating detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

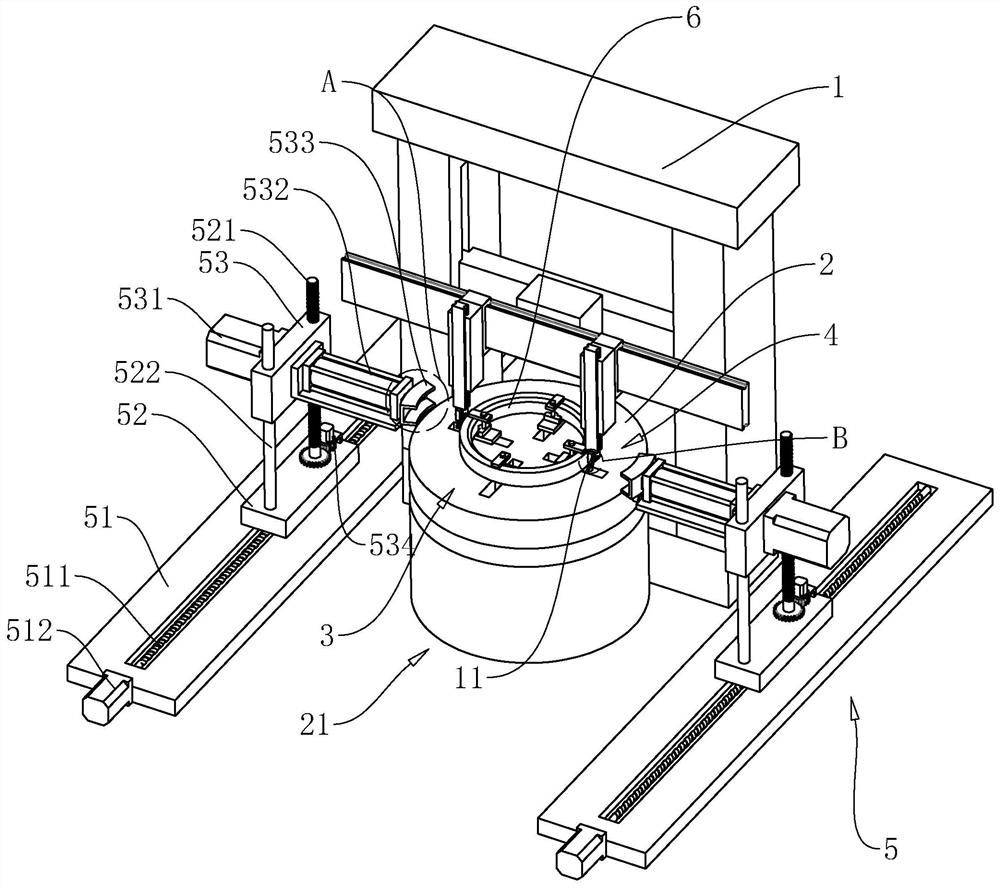

[0042] The following is attached Figure 2-6 The application is described in further detail.

[0043] The embodiment of the present application discloses a vertical lathe for processing distance rings.

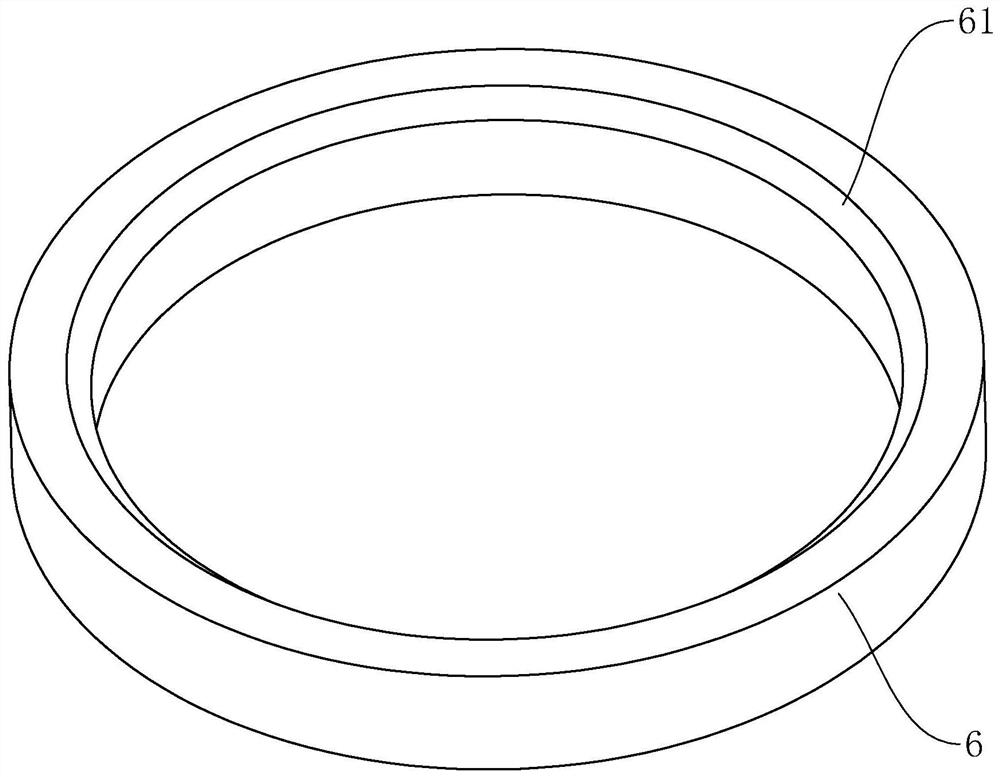

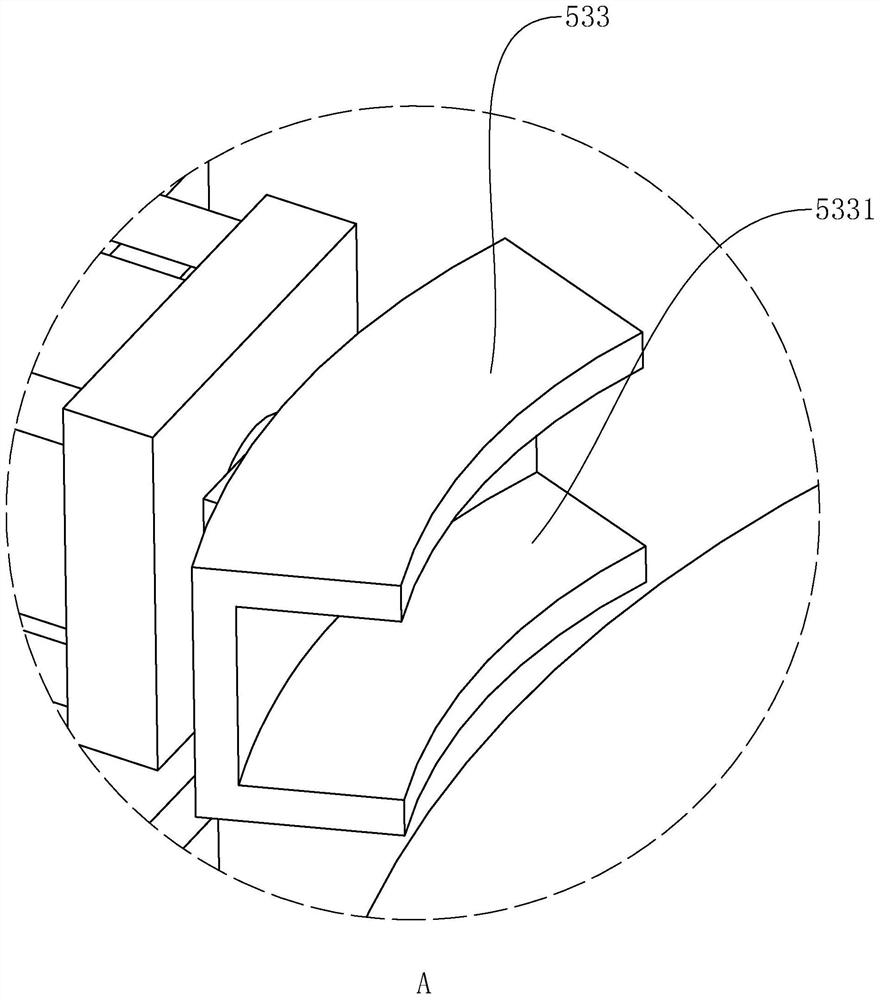

[0044] refer to figure 2, the vertical lathe comprises a lathe body 1 and a vertical chuck 2, a tool rest 11 is installed on the lathe body 1, and the tool rest 11 can move vertically and radially of the spacer ring 6, and the tool rest 11 is positioned on the vertical chuck 2, there can be two tool rests 11, oppositely arranged along the width direction of the lathe body 1. The bottom of the vertical chuck 2 is provided with a driving device 21 for driving the vertical chuck 2 , and the vertical chuck 2 is provided with an automatic clamping device 3 for clamping the spacer ring 6 . A detection device 4 is also provided on the tool rest 11 for detecting the coaxiality and flatness of the spacer ring 6 . Both sides of the vertical chuck 2 are provided with feeding devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com