Five-link suspension system and vehicle

A suspension system and five-link technology, which are applied to the five-link suspension system and the field of vehicles, can solve problems such as unfavorable vehicle stability, poor suspension toe-in curve, etc., and achieve the effect of improving vehicle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

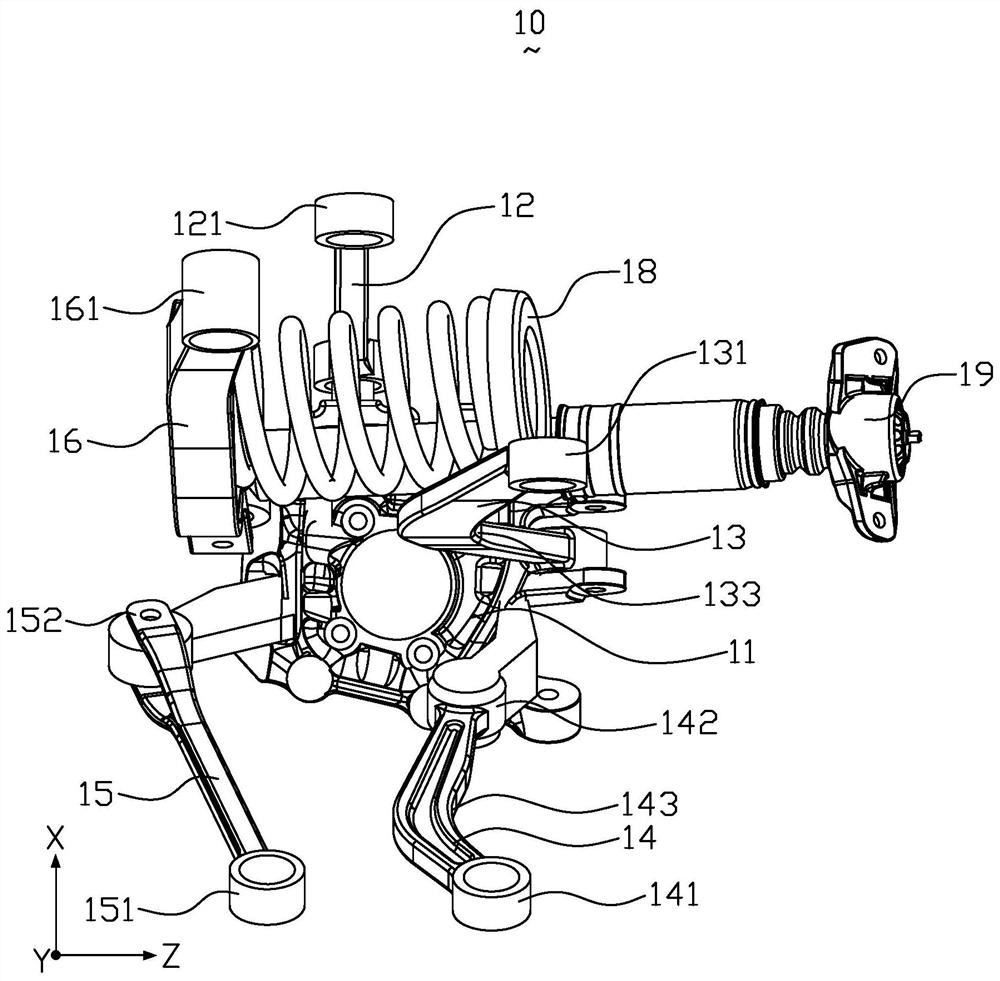

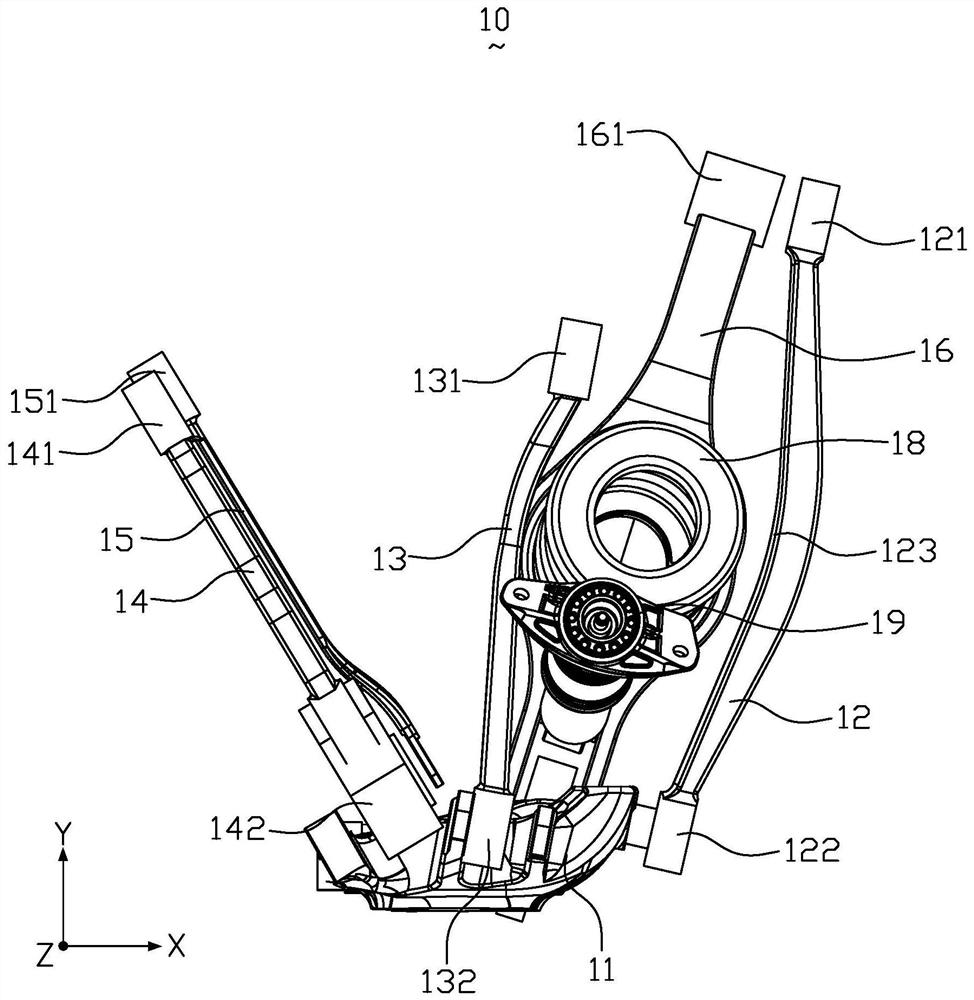

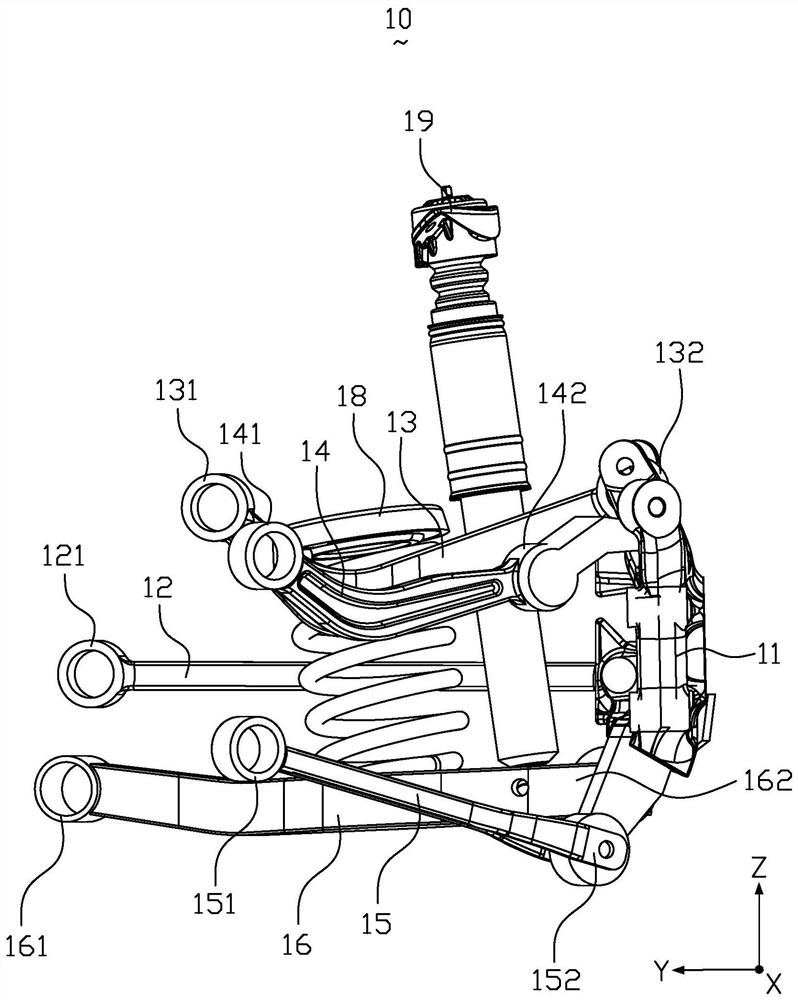

[0027] Figure 1 to Figure 4 is a three-dimensional structural schematic diagram of the five-link suspension system of the present invention, please refer to Figure 1 to Figure 4 , the five-link suspension system 10 includes a steering knuckle 11, a toe-in arm 12, a sway arm 13, a guide arm 14, a trailing arm 15, a control arm 16, a subframe (not shown), a spring 18 and a shock absorber Device 19. Define the vehicle body length direction as the first direction X, the vehicle body width direction as the second direction Y, wherein the first direction X is perpendicular to the second direction Y, and the vehicle body height direction as the third direction Z, wherein the first direction X and the second direction Y and the third direction Z are perpendicular to each other, and a rectangular coordinate system is established with the first direction X, the second direction Y and the third direction Z, and the origin of the rectangular coordinate system is located at the midpoint o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com