Agricultural environment-friendly straw smashing device

A kind of straw crushing and environment-friendly technology, applied in agriculture, combined devices, agricultural machinery and implements, etc., can solve problems such as air pollution and affecting human health, and achieve the effect of avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

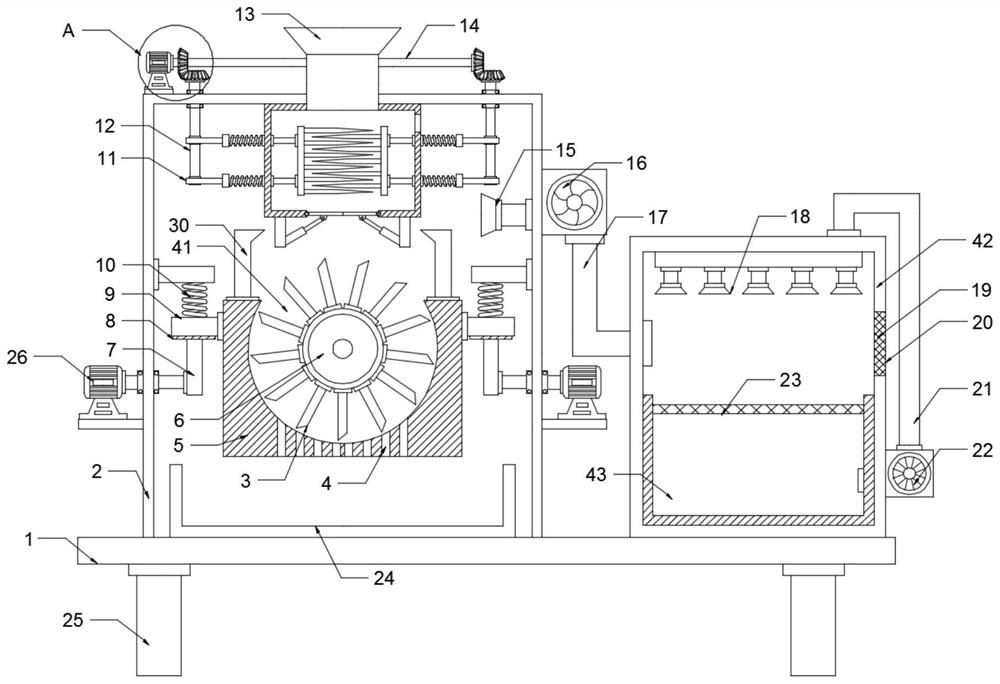

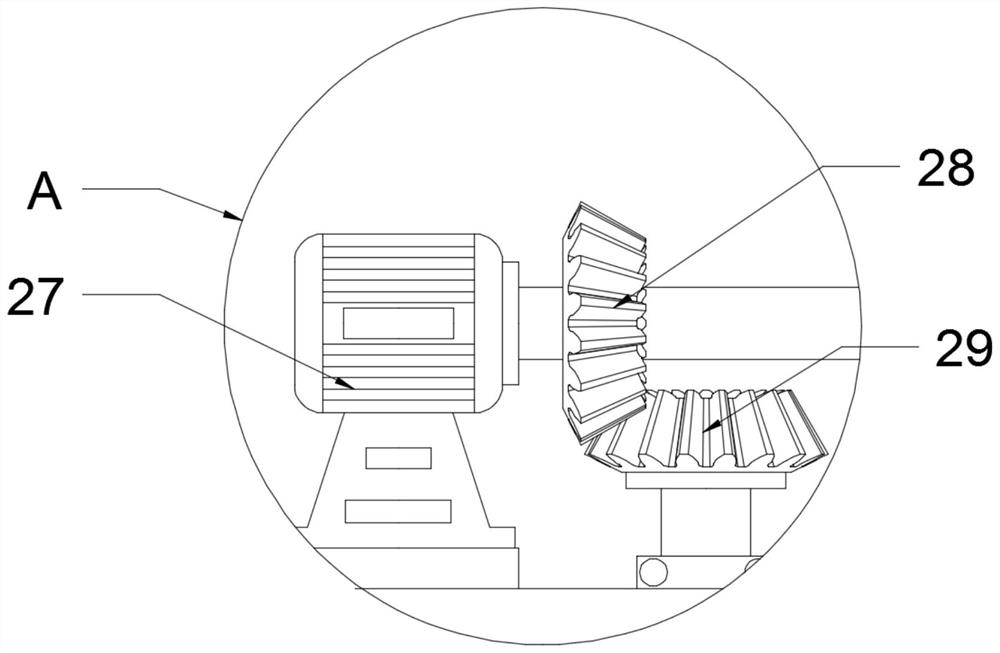

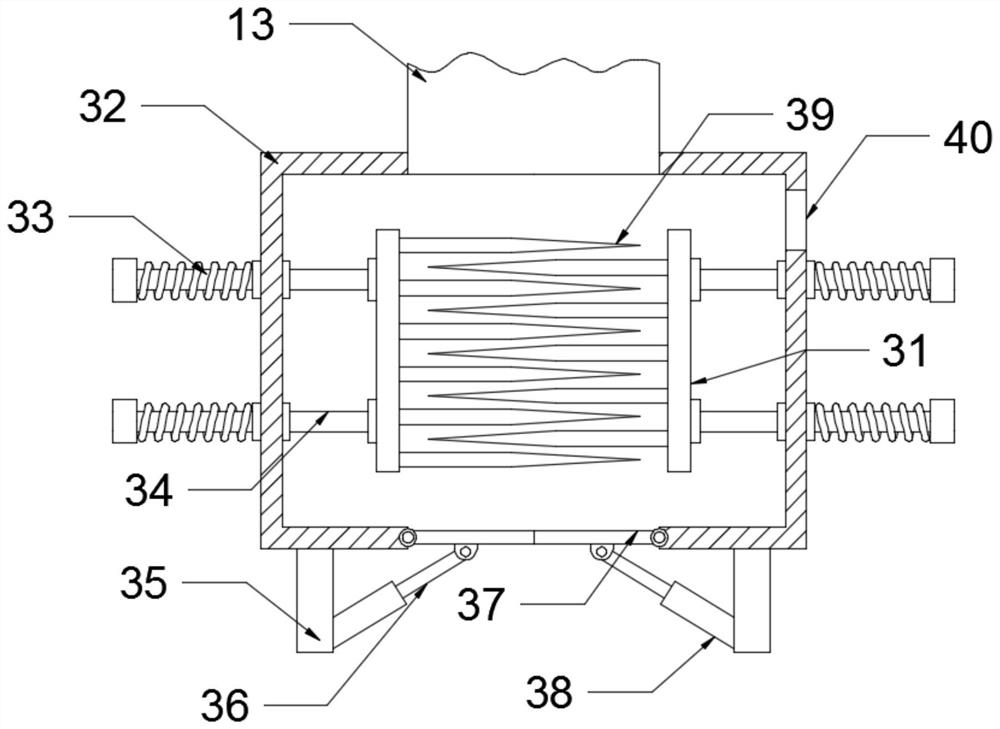

[0022] see Figure 1-4 , an environmentally friendly agricultural straw crushing device, comprising a support base 1 and a crushing box 2, the crushing box 2 is installed on the upper surface of the support base 1, the crushing box 2 and the support base 1 are fixedly connected by welding, the A feed box 32 is arranged above the crushing box 2, and a feed inlet 13 is arranged above the feed box 32, and the feed inlet 13 is extended and connected to the top of the crushing box 2, and the left side of the upper surface of the top wall of the crushing box 2 is arranged Drive motor one 27, described drive motor one 27 output ends are fixedly connected to rotating shaft 14, described rotating shaft 14 left and right sides are symmetrically provided with bevel gear one 28, and described pulverizing box 2 inner upper left and right sides are symmetrically provided with rotating rod 12, described The rotating rod 12 is rotationally connected with the top wall of the crushing box 2, an...

Embodiment 2

[0029] see figure 1, on the basis of Example 1, in order to process the dust generated during crushing in the crushing box 2, a filter box 42 is arranged on the right side of the upper surface of the support base 1, and a fan 16 is arranged above the right side wall of the crushing box 2, The fan 16 is connected to the air duct 17, the air duct 17 on the left side extends through the crushing box 2 and connects to the dust suction port 15, and the air duct 17 on the right side is extended and connected to the filter box 42, and the bottom of the filter box 42 is A water tank 43 is set, and a water pump 22 is set on the right side wall of the filter box 42, and the water pump 22 is connected to a water pipe 21, and the end of the water pipe 21 away from the water pump 22 is extended and connected to the filter box 42, and sprinklers are arranged equidistantly below the water pipe 21 18. An air outlet 20 is provided on the right side wall of the filter box 42, and a fine filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com