Spring hanger capable of improving output rigidity and design method thereof

A spring hanger and stiffness technology, applied in the direction of springs/shock absorbers, coil springs, mechanical equipment, etc., can solve the problems of manufacturing difficulties, installation and production troubles, increase manufacturing costs and time, and achieve the effect of improving output stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

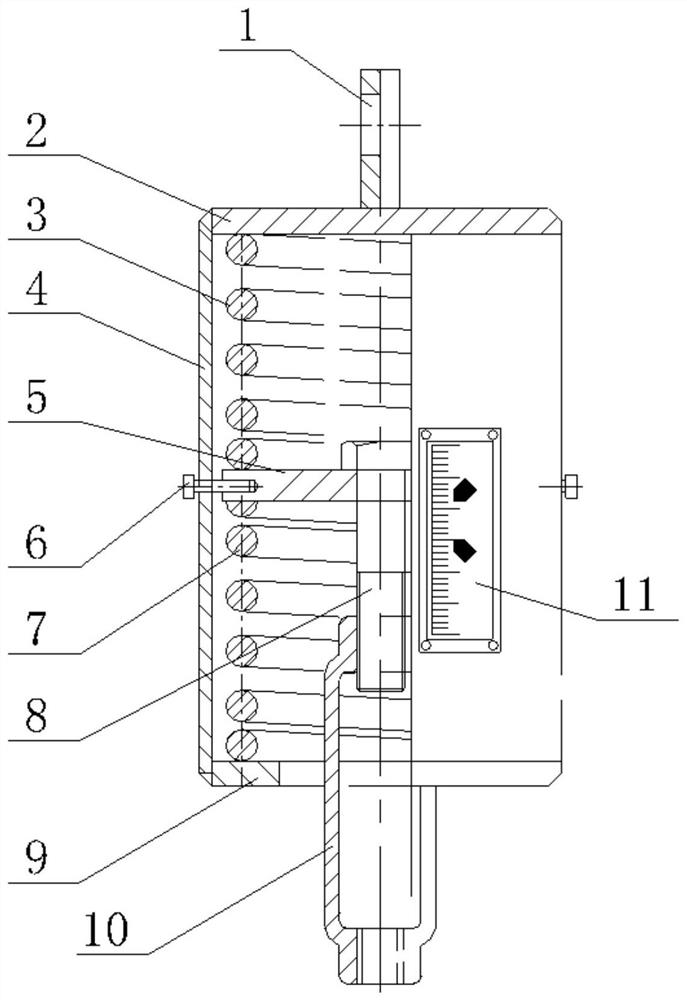

[0019] refer to figure 1 , the spring hanger that can improve the output stiffness of the present invention includes an upper end plate 2, a cylinder body 4, a lower end plate 9, a spring pressure plate 5, an upper spring 3, a lower spring 7, a hex head bolt 8, a turnbuckle screw 10 and a positioning Pin 6; the upper end plate 2 is fixed at the top opening of the cylinder 4, the lower end plate 9 is fixed at the bottom opening of the cylinder 4, the spring pressure plate 5 is located in the cylinder 4, and the upper spring 3 is located between the upper end plate 2 and the spring pressure plate 5 The lower spring 7 is located between the lower end plate 9 and the spring pressure plate 5; the lower end of the hex head bolt 8 passes through the middle of the spring pressure plate 5 and connects with the upper end of the turnbuckle screw 10, and the lower end of the turnb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com