Novel infrared laser plumb bob

An infrared laser and pendulum hammer technology, which is applied to plumb lines, measuring devices, instruments, etc., can solve the problems of low work efficiency, increased construction cost, and low work efficiency of the pendant hammer, and is conducive to popularization and use and increased stability , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

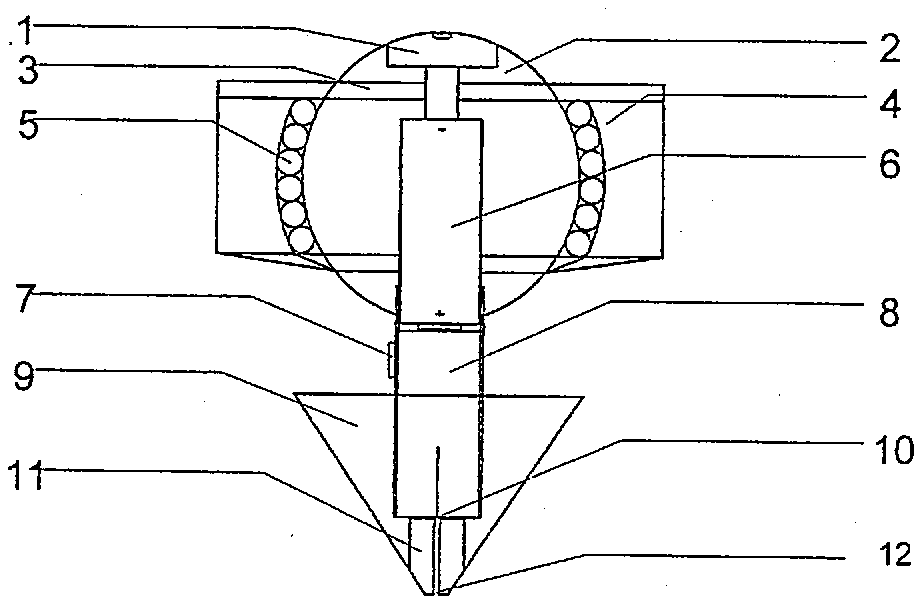

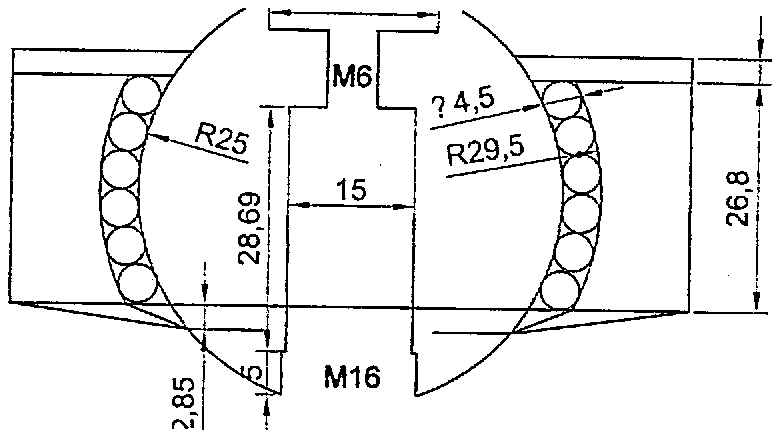

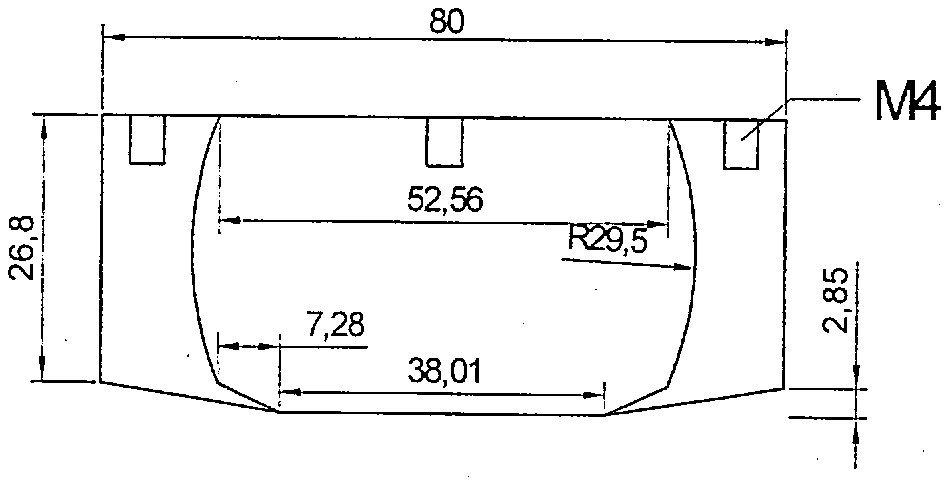

[0041] Embodiment one: if figure 1 As shown, a new type of infrared laser pendant hammer described in this embodiment includes the horizontal bubble 1 installed at the top of the universal ball 2, and the infrared emitter 8 installed at the The bottom end position of the universal ball 2 is concentric and perpendicular to the installation position of the horizontal air bubble 1. The universal ball 2 is installed in the universal ball bearing shell 4, and the universal ball Put steel balls 5 evenly around 2, the universal ball bearing housing cover 3 is installed on the top of the universal ball bearing housing 4 and fixed with 4 screws, and in the inner cavity at the bottom of the universal ball bearing 2 The battery 6 is installed, and the hollow conical counterweight 9 is installed at the bottom of the infrared transmitter 8, and the hollow conical counterweight 9 is installed at the bottom of the hollow conical counterweight 9. Tapered counterweight hammer body tip 11.

...

Embodiment 2

[0044] Embodiment two: see figure 1 It is the same as Embodiment 1 and has the same meaning, and the same parts will not be repeated.

[0045] The difference is: the hollow conical counterweight hammer body 9 and the infrared emitter 8 can predict the principle that the universal ball bearing will naturally sag and maintain a stable level, adding a ray for measuring the level.

Embodiment 3

[0046] Embodiment three: see figure 1 It is the same as Embodiment 1 and has the same meaning, and the same parts will not be repeated.

[0047] The difference is: the appearance can be changed into many forms.

[0048] 1. The universal ball bearing housing cover is movable and replaceable, and the purpose of replacement is to fix the bracket such as the level.

[0049] 2. A plane is reserved on the side of the arc of the universal ball bearing housing. When measuring the verticality of a wall or object, lean against the surface plane of the wall or object, and the plane will be more stable against the plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com