Vehicle photovoltaic unfolding device and working method

A technology for photovoltaics and vehicles, applied in the field of photovoltaic deployment devices for vehicles, which can solve the problems of conventional use, large volume of photovoltaic modules, unfavorable handling of photovoltaic modules, etc., and achieve the effect of large power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

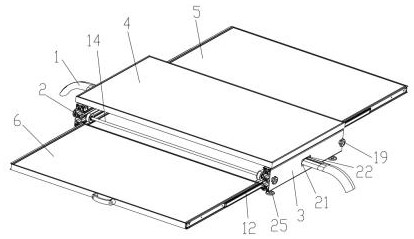

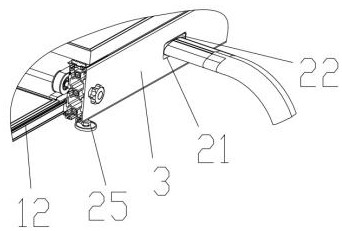

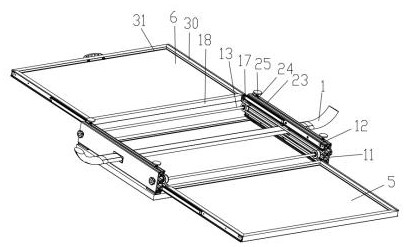

[0031] The vehicle photovoltaic deployment device of the present invention includes a mounting beam 1 arranged on the roof of the vehicle and a left mounting frame 2 and a right mounting frame 3 oppositely arranged on the mounting beam. The mounting beam 1 may have a circular or elliptical cross-section, etc. The aluminum pipe is bent and formed, and the two ends of the installation beam 1 are connected to the roof through the support base. The support base can be a pipe sleeve with a flange. The screws are locked on the roof; the first photovoltaic panel 4, the second photovoltaic panel 5 and the third photovoltaic panel 6 are arranged from top to bottom between the left and right installation frames, and the first photovoltaic panel 4 is fixed on the left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com