Silicon carbide smelting process

A silicon carbide and process technology, applied in silicon carbide, carbide and other directions, can solve the problems of high energy consumption, high production cost and low quality of silicon carbide smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Please refer to the attached figure 1 , which shows the flow of the silicon carbide smelting process provided by this application.

[0033] A silicon carbide smelting process, including four processes, respectively:

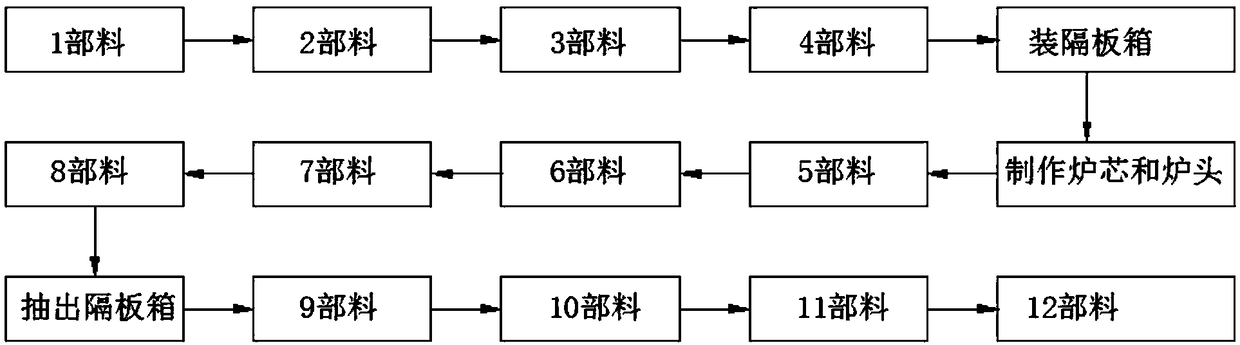

[0034] (1) Material preparation: select carbonaceous materials and quartz sand; mix carbonaceous materials and quartz sand according to the preset ratio to form smelting raw materials; the preset ratio includes 12 kinds of ratios, corresponding to the first to the twelfth The raw materials of the sub-materials, 12 kinds of sub-materials together form the smelting raw materials.

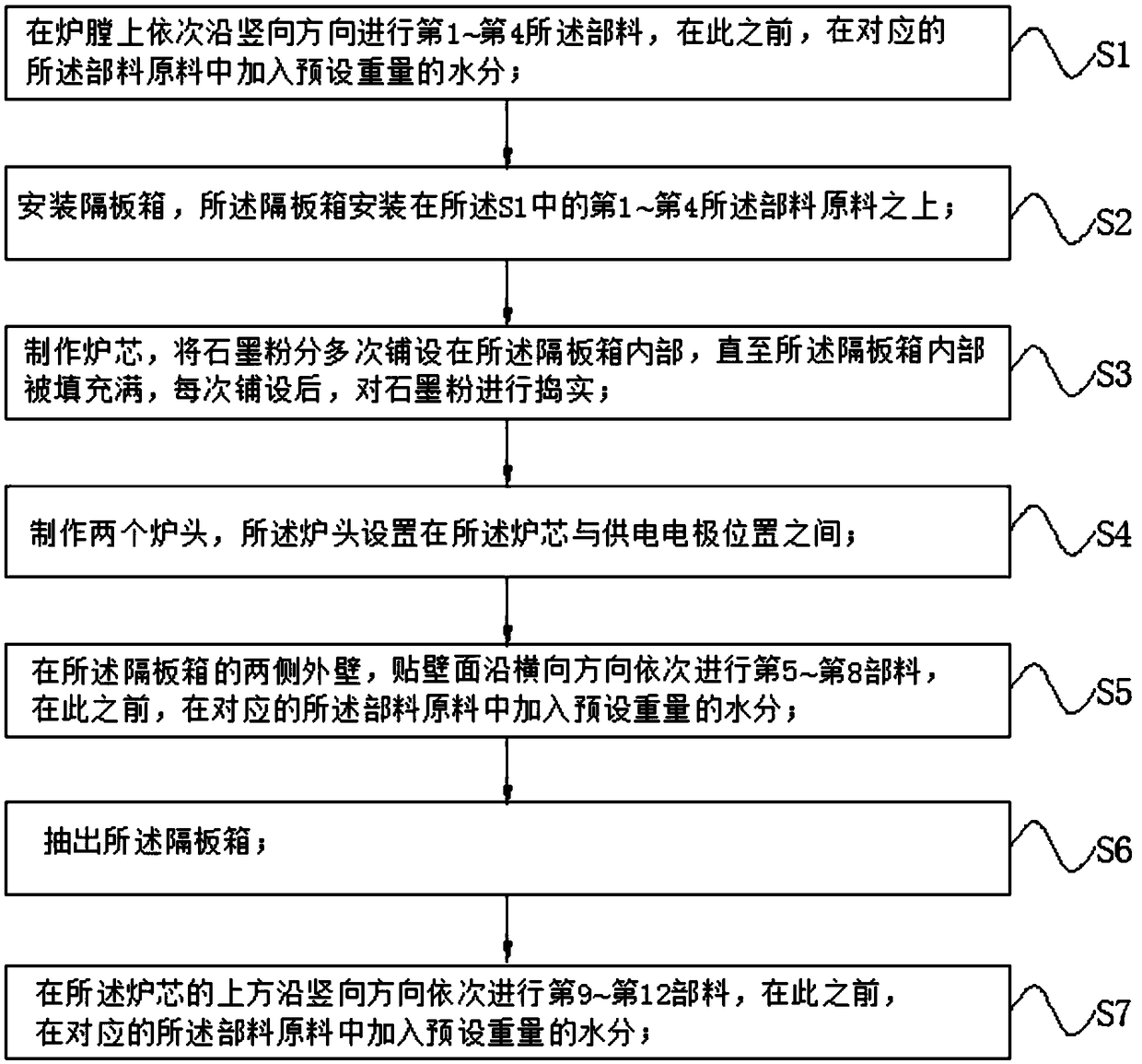

[0035] (2) Furnace loading process includes: Step S1 Carry out the first to fourth batches in the furnace along the vertical direction in sequence, and before that, add a preset weight of water to the raw materials of the corresponding batches.

[0036] Step S2 installs the partition box, and the partition box is installed on the raw materials of the first to fourth parts in S1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com