Prefilter

A pre-filter and filter element technology, applied in the field of filters, can solve the problems of inconvenient cleaning and sewage discharge, and achieve the effect of improving the convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

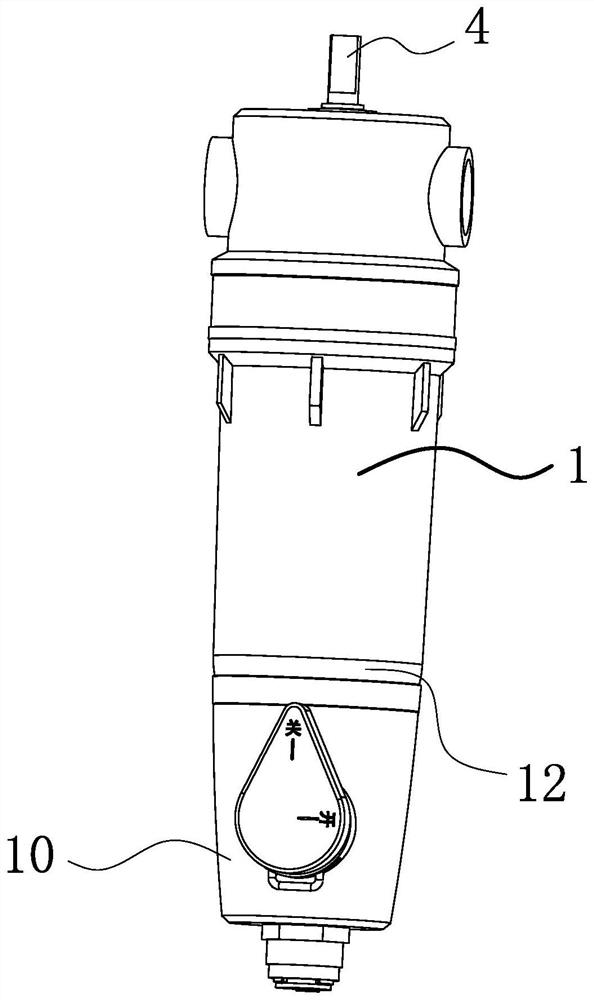

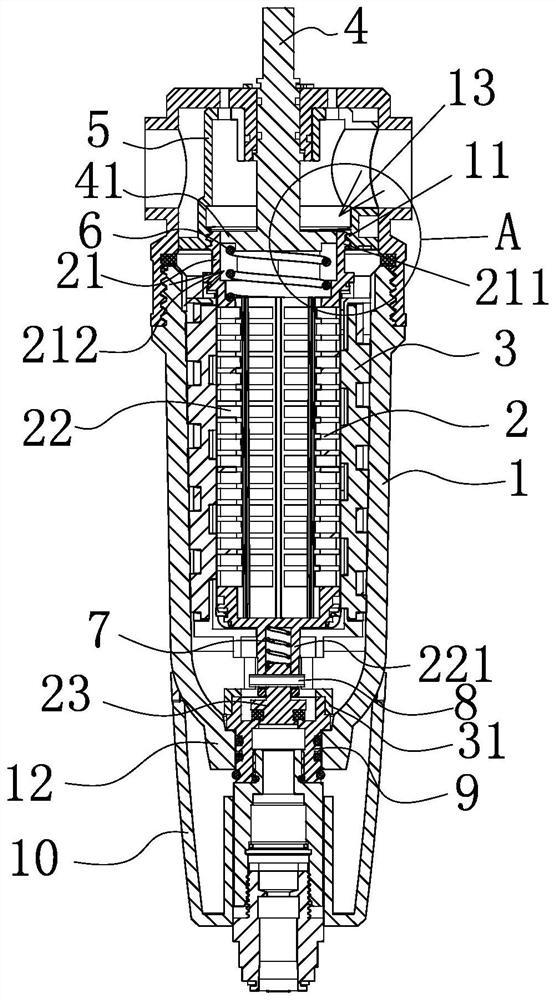

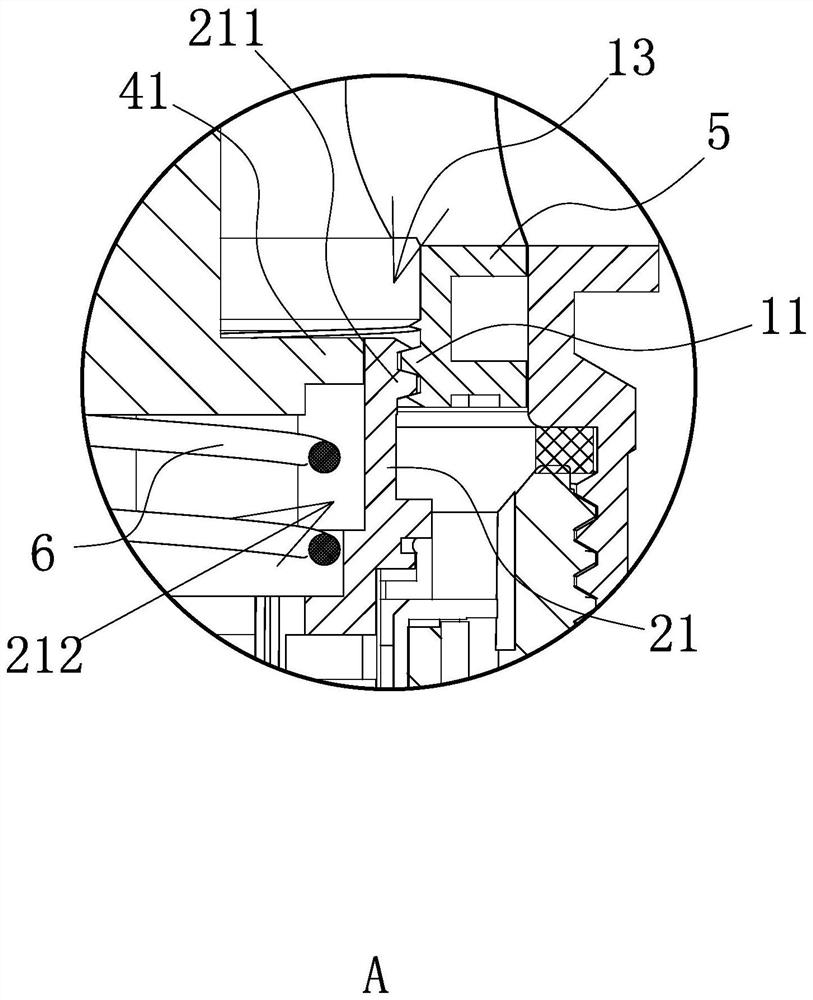

[0042] like Figure 1-Figure 3 A pre-filter shown is composed of housing 1 , brush 3 , filter element 2 and other components. The housing 1 is cylindrical and has oppositely arranged water inlet and water outlets on its upper outer peripheral surface. The top of the inner cavity of the housing 1 is fixedly connected with a mounting seat 5, and the lower end of the housing 1 is also provided with a housing 1 The sewage discharge end 12 that the inner chamber communicates with the outside. The side of the mounting base 5 has a connection port docked with the water outlet, the lower end of the mounting base 5 is open, and the filter element 2 is connected to the opening, so that when the water inlet end enters the water, the water flow can fill the entire inner cavity of the housing 1 and flow into it. In the inner cavity of the filter element 2, when water flows through the filter element 2, the impurities in the water flow are isolated by the filter element 2 and left on the o...

Embodiment 2

[0049] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the valve stem 4 in this embodiment is directly fixedly connected with the connector 21 on the filter element 2, and the valve stem 4 is slidably arranged in the mounting seat 5 , realize the rotation by connecting with an external controller, and achieve the same technical effect as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com