Food sorting device for cold-chain logistics

A sorting device and cold chain logistics technology, applied in packaging, solid separation, filtering and screening, etc., can solve problems such as sticking, single sorting method of sorting machine, and affecting product quality, so as to improve structural rationality, flexibility and practicality The effect of improving performance and meeting the use of materials of multiple sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

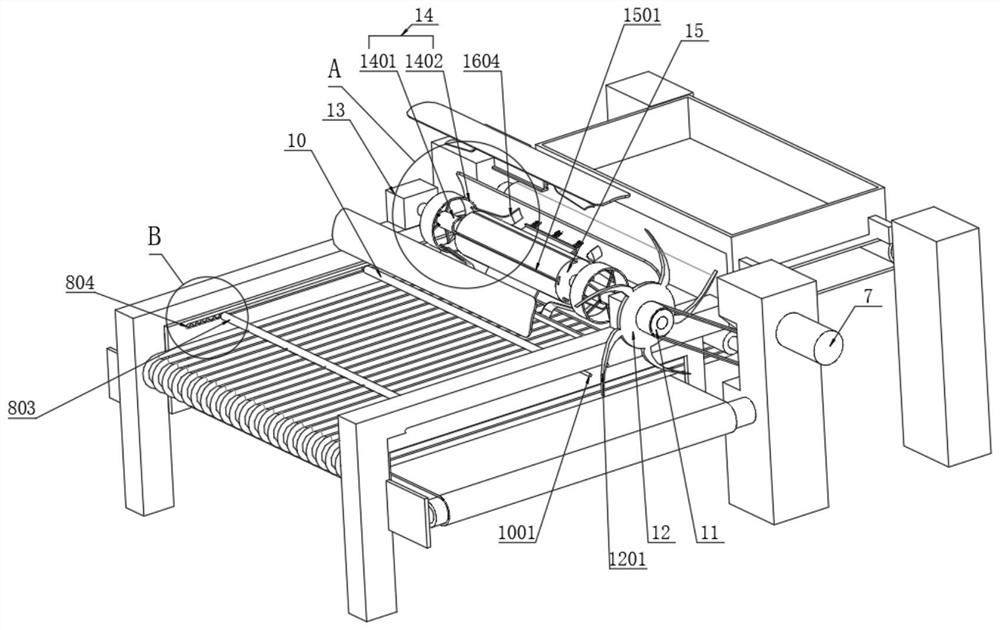

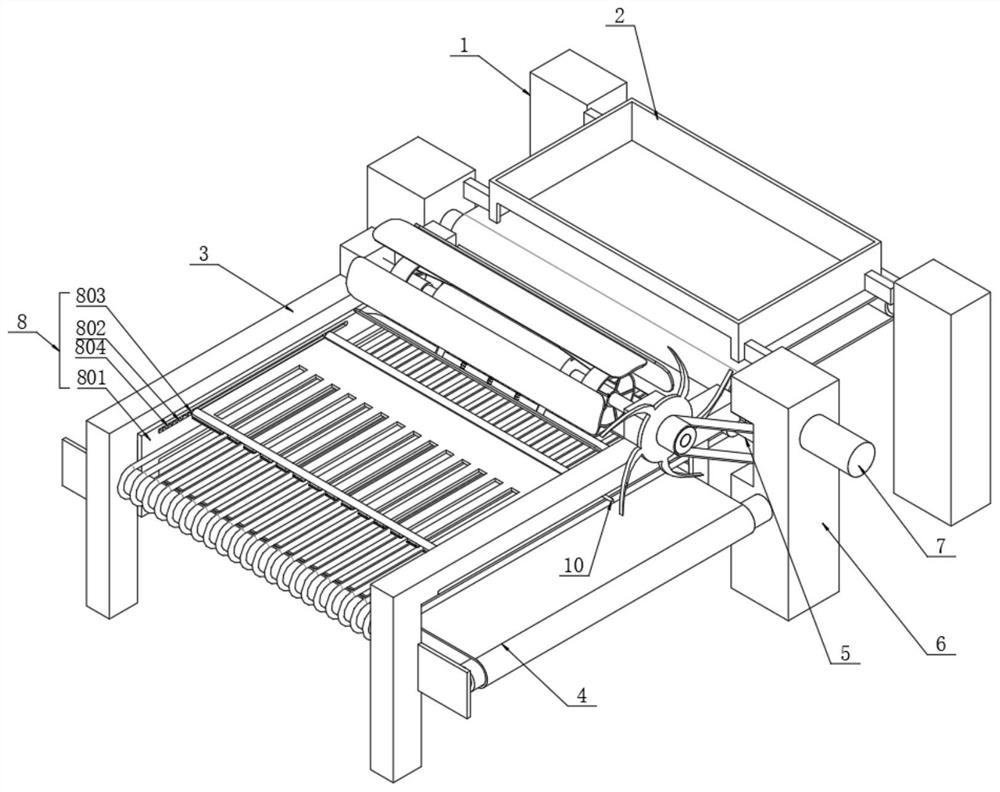

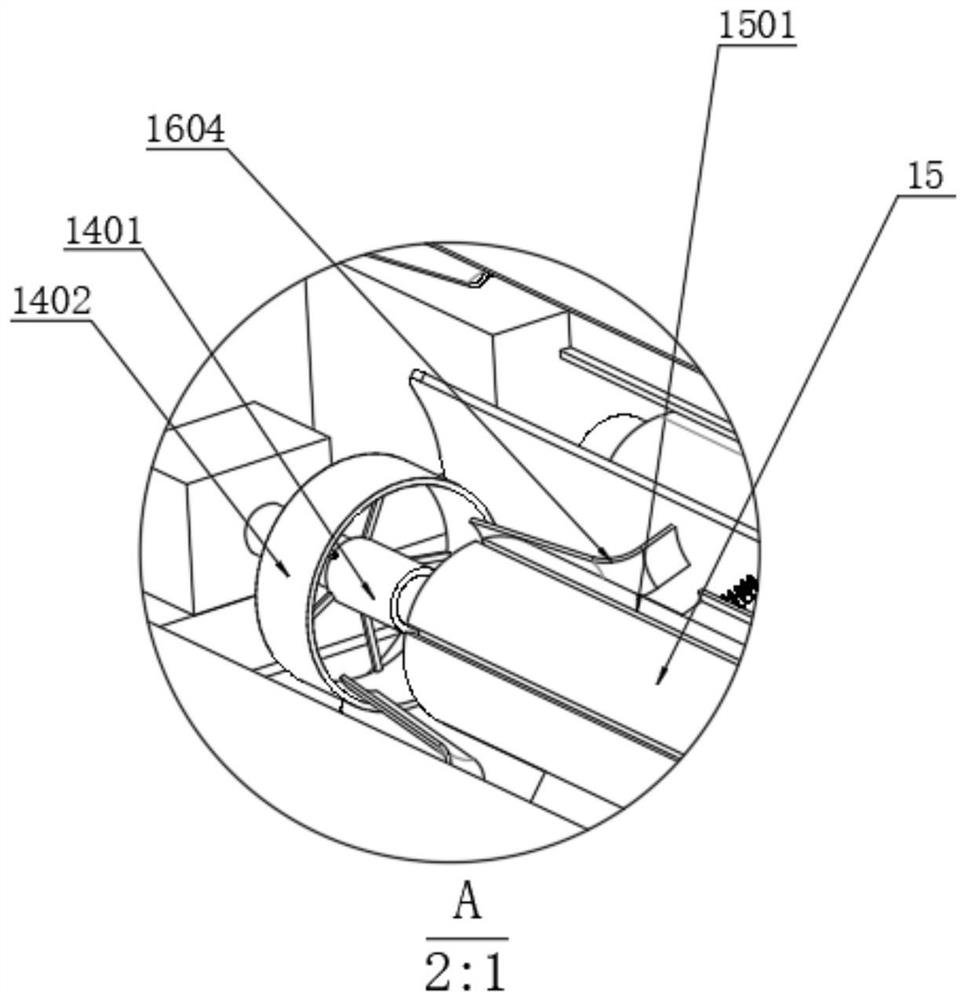

[0031] see Figure 1 to Figure 9 , a food sorting device for cold chain logistics, including a feeding rack 1, a tension mechanism 8, a pull belt mechanism 9 and a material turning mechanism 16, and a running belt type loading hopper 2 is fixed on the top of the feeding rack 1, The discharge side of the loading rack 1 is fixed with a conveyor rope-type sorting rack 3 for picking up the materials discharged from the upper hopper 2, and the bottom of the sorting rack 3 is provided with a drain for smaller particle materials leaked during sorting. Material rack 4, larger granular materials are discharged forward by the transmission rope on the sorting rack 3, and the discharge rack 4 discharges the received small granular materials to both sides, and the right side of the feeding rack 1 is provided with a gear box tripod 6 , the top of the gear box tripod 6 is equipped with a gear box, and the outer end of the gear box tripod 6 is equipped with a transmission motor 7 for driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com