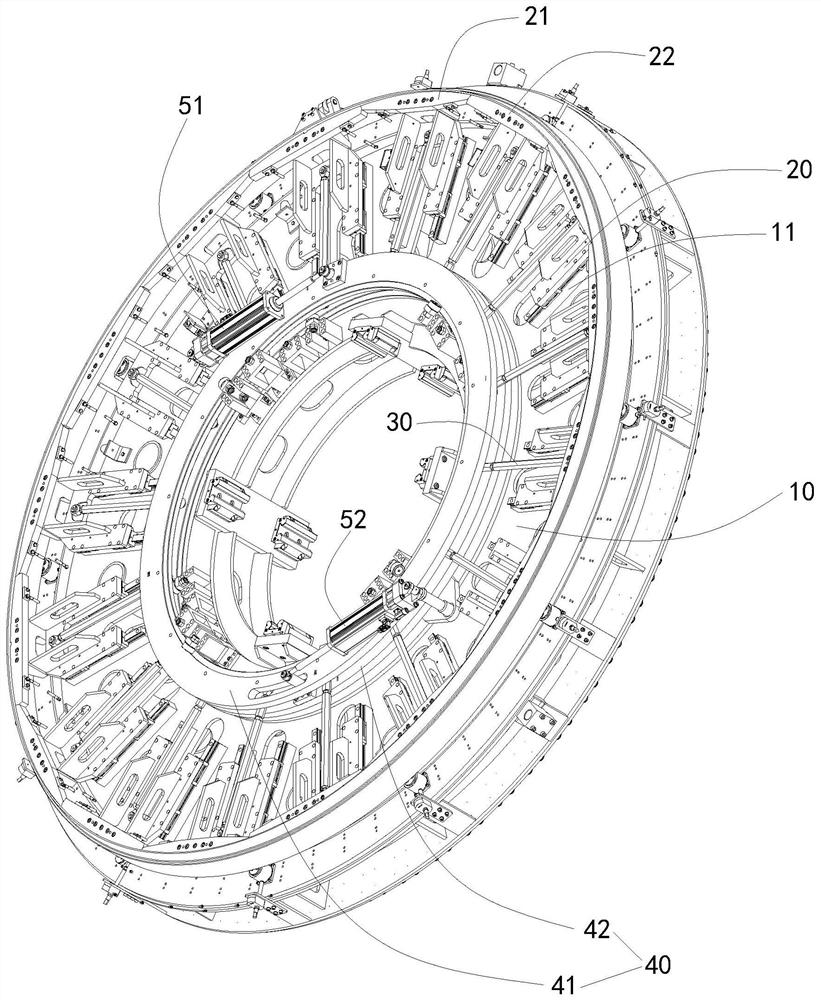

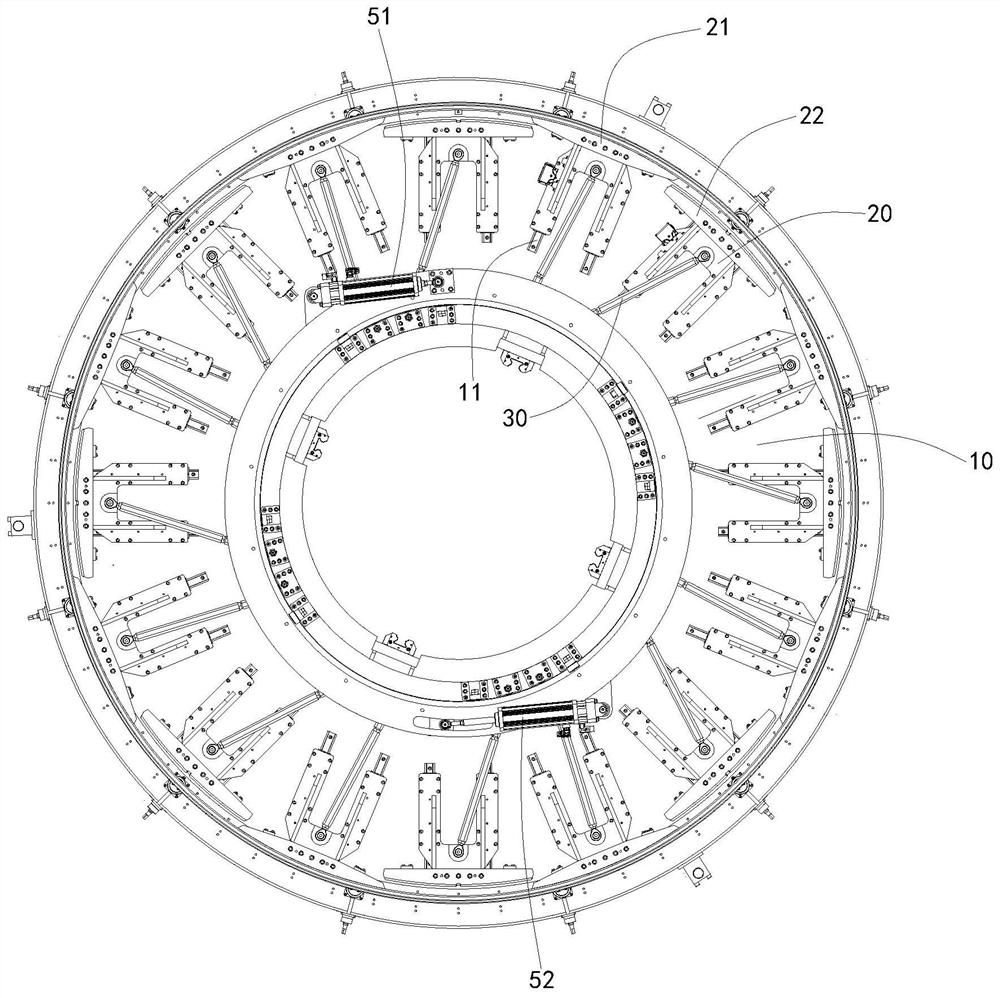

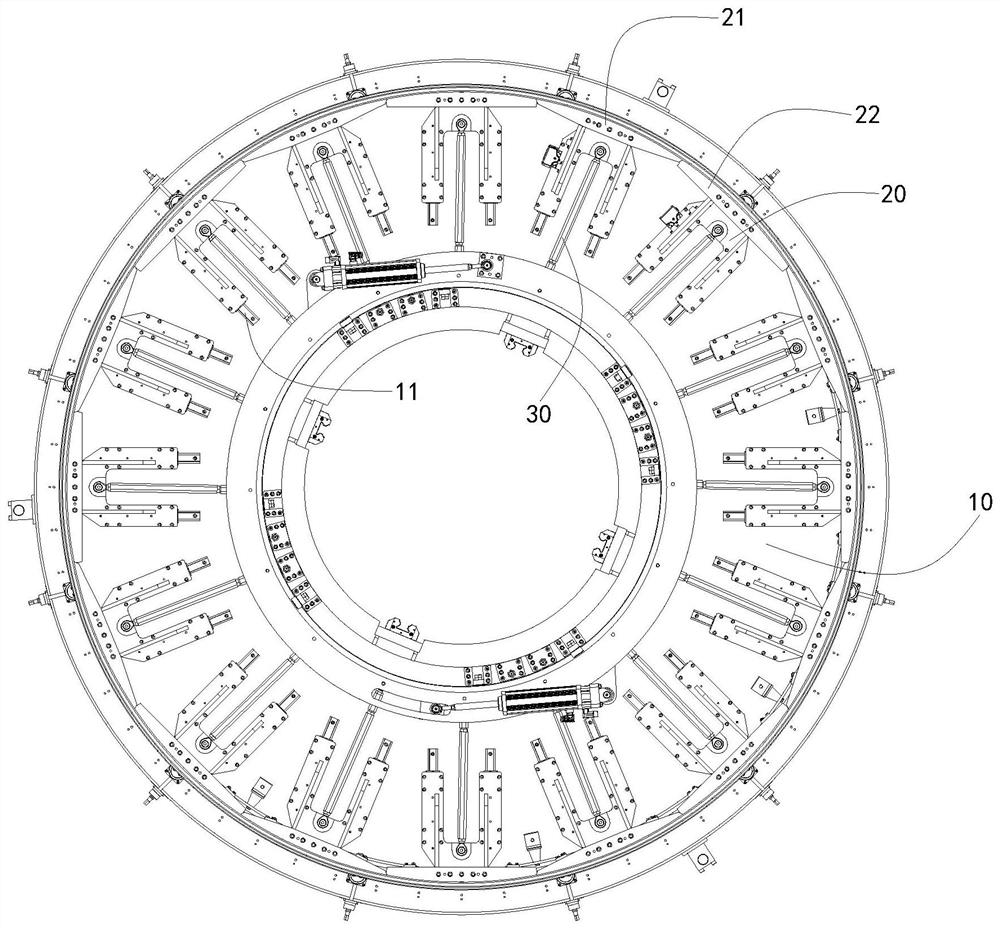

Servo driven girth welding internal supporting device for storage tank

A servo drive and drive ring technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of difficulty in ensuring the seamless fit between the inner support and the bottom of the tank, and achieve the effect of improving the precision and quality of tailor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Such as Figure 1~3 As shown, the present invention provides a servo-driven storage tank girth welding inner support device, the inner support device includes: an installation body 10, a slide table 20, a connecting rod 30, a drive ring 40 and a servo electric cylinder; The mounting body 10 is radially provided with a linear guide rail 11, the slide table 20 is slidably connected with the linear guide rail 11, the slide table 20 slides freely along the linear guide rail 11, and the outer end of the slide table 20 is provided with a support block, The inner end of the slide table 20 is hinged with the drive ring 40 through the connecting rod 30, the drive ring 40 is rotatably connected with the installation body 10, the drive ring 40 freely rotates around the central axis of the installation body 10, and the servo electric cylinder One end is hinged with the installation body 10, and the other end is hinged with the driving ring 40.

[0032] During the process of locati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com