Processing equipment and processing method for socket sealing ring embedding groove of winding structure wall pipe

A technology for structural wall pipes and sealing rings, which is applied in the processing equipment and processing field of socket sealing ring embedding grooves, which can solve the problems that the socket sealing ring embedding grooves cannot be mechanized, and achieve the effect of stable position and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

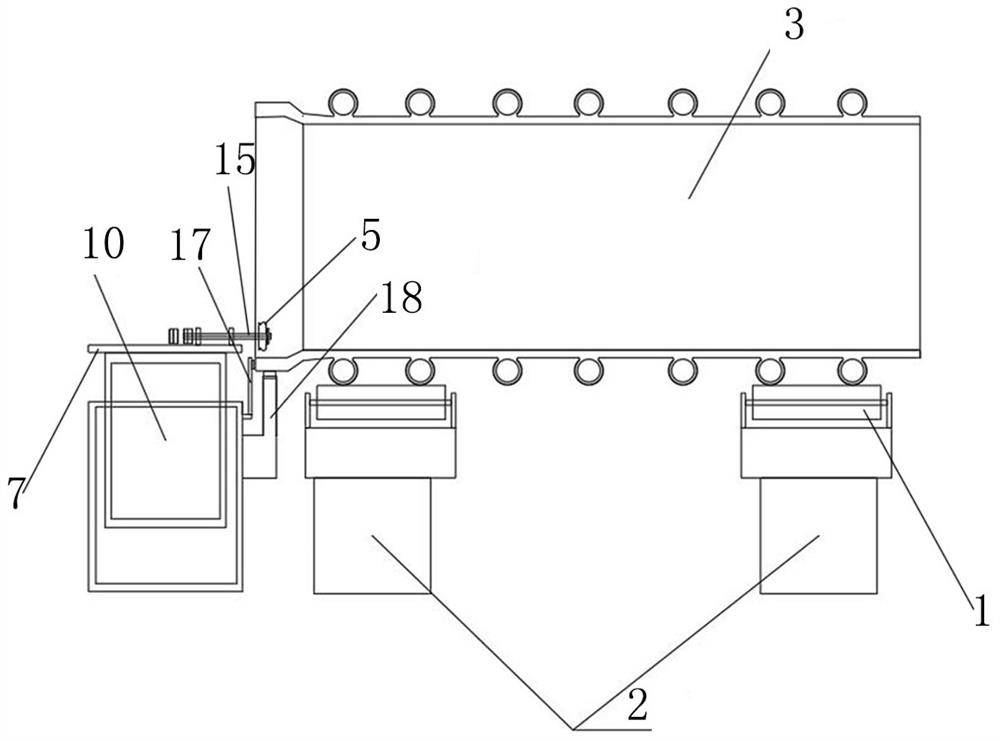

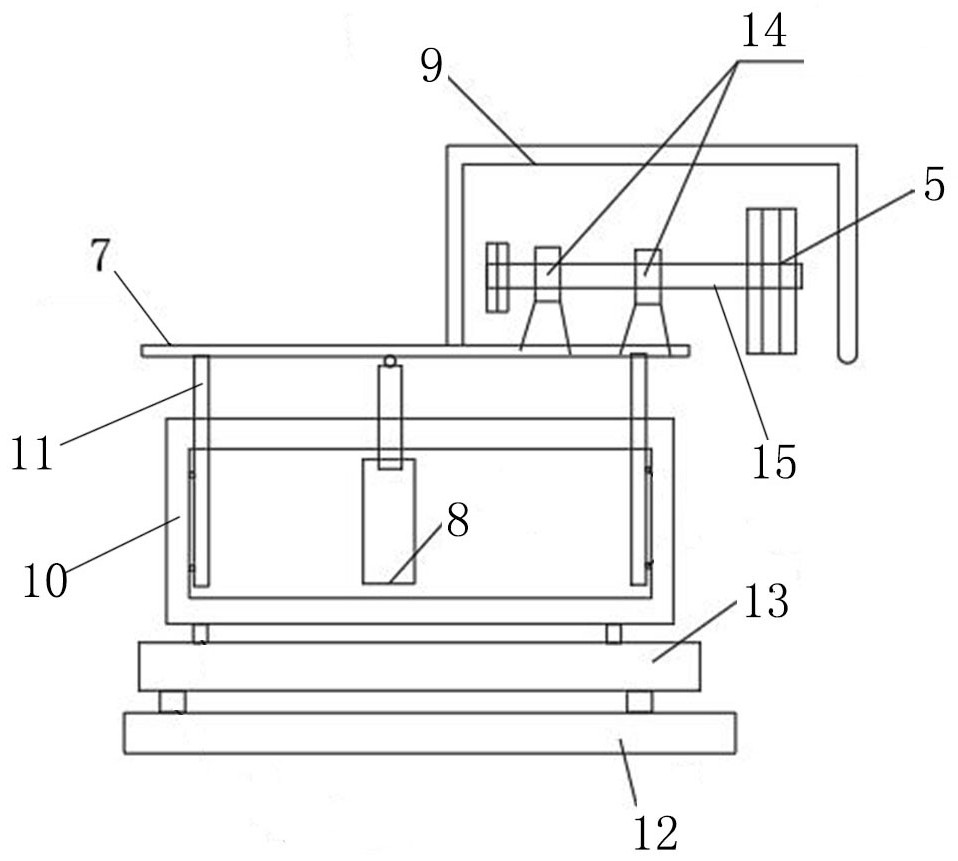

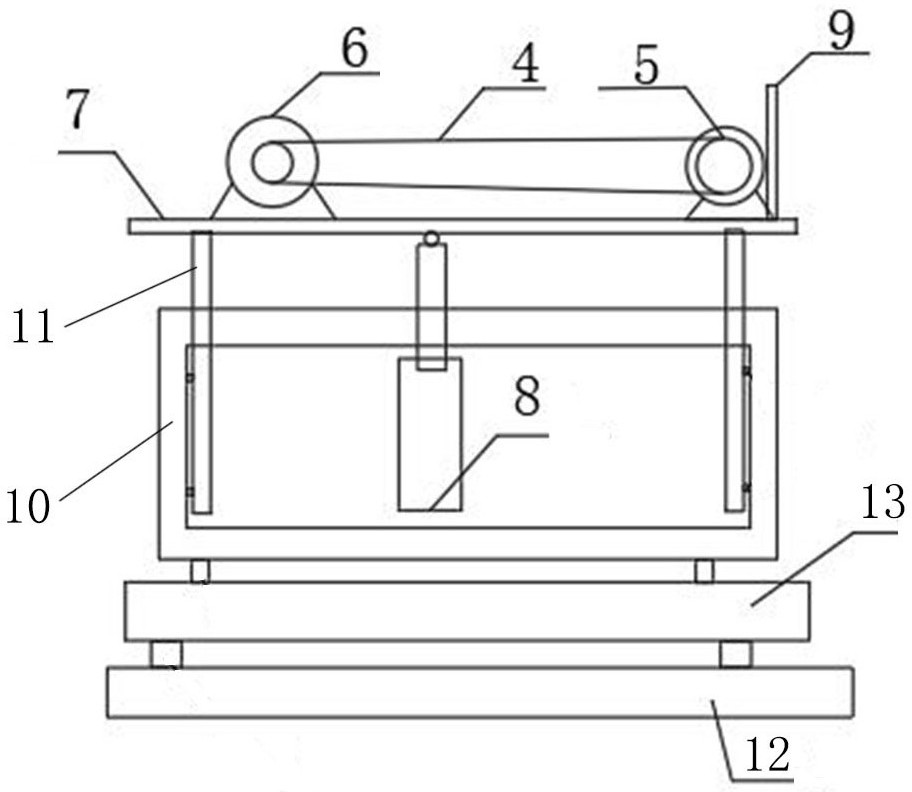

[0033] Such as figure 1 As shown, the socket sealing ring embedding processing equipment of the present invention includes three parts: the rotating drive device for the wall pipe of the winding structure, the embedding cutting processing device and the socket positioning mechanism. The winding structure wall pipe rotation driving device is used to horizontally support the pipe body of the winding structure wall pipe 3 and drive the winding structure wall pipe 3 to rotate around the axis. The slot cutting processing device is used to radially process a ring-shaped slot ( Figure 4 ). The socket positioning mechanism is arranged on the frame of the slot cutting processing device, which includes a socket end face positioning frame 17 and a socket supporting roller 18, and the socket end face positioning frame 17 is used for axially positioning the winding structure wall pipe 3. Positioning, the socket supporting roller 18 is used for positioning the cutting section of the sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com