Anti-unhooking mechanism for tower crane hoisting

A decoupling and arc-shaped technology, which is applied in the field of anti-decoupling mechanisms for tower cranes, can solve problems such as low safety factor, material falling off, and material damage, and achieve the effects of improved stability, good detachment prevention effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

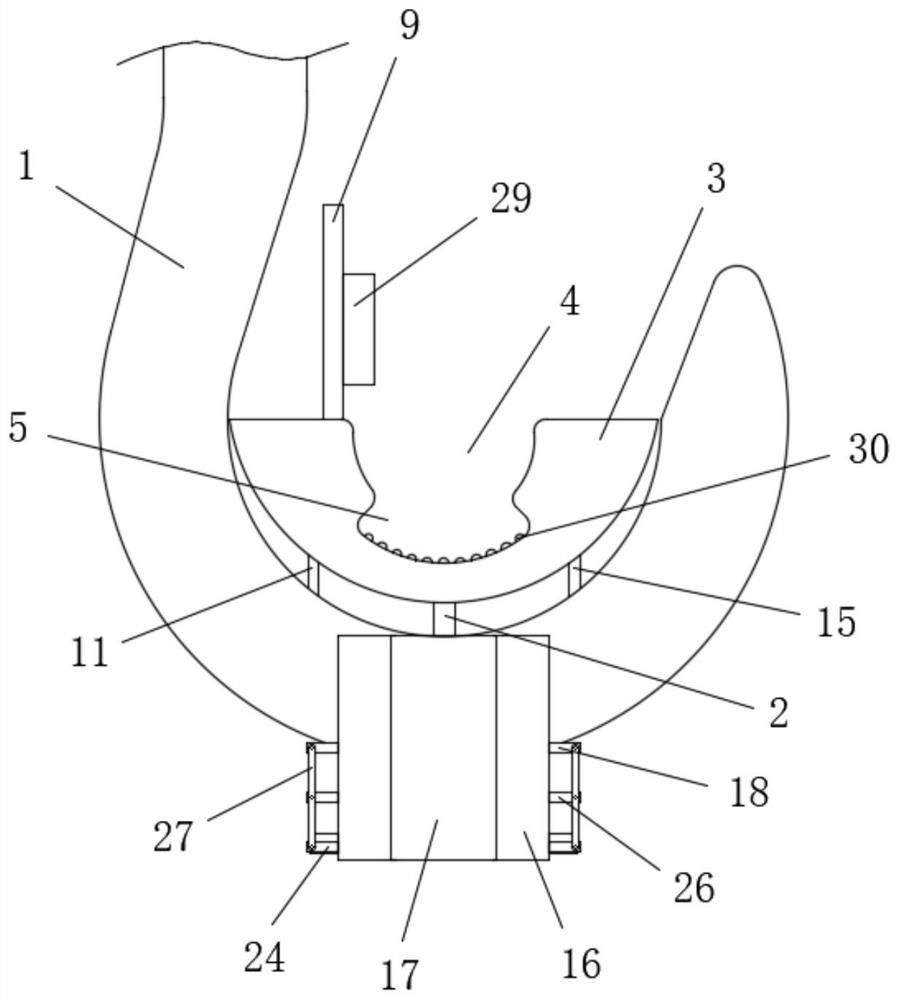

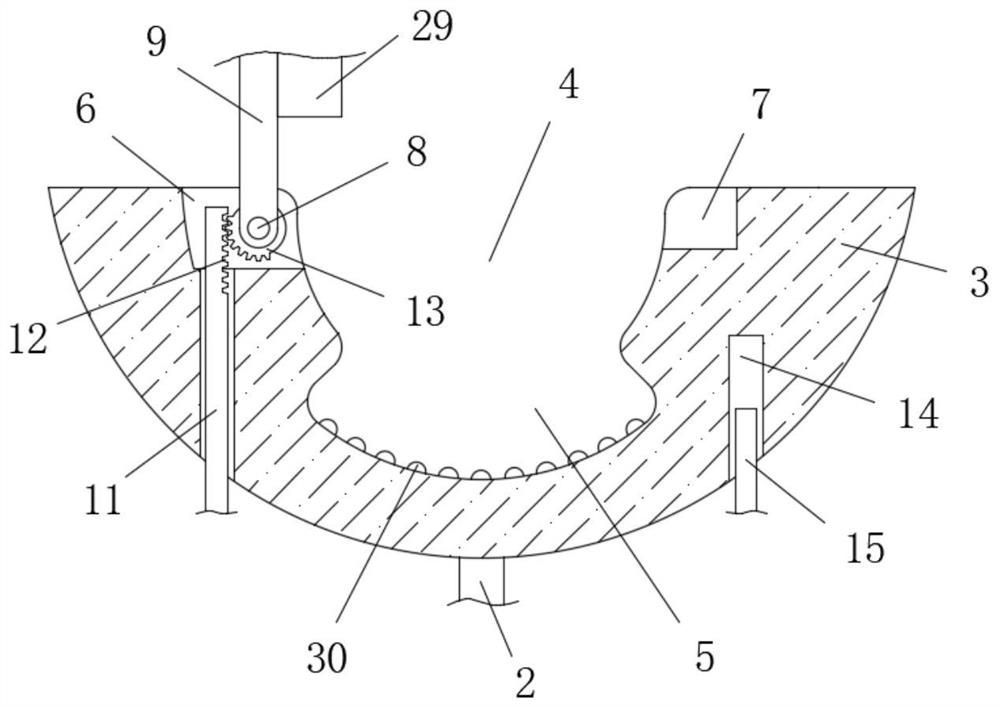

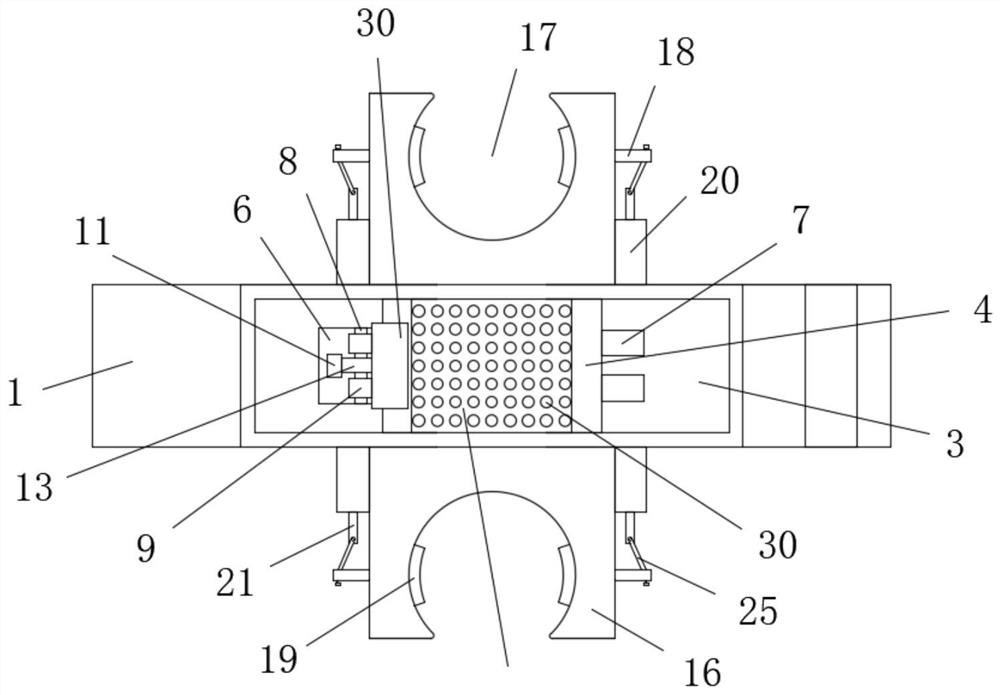

[0027] refer to Figure 1-7 , an anti-drop hook mechanism for tower hoisting, comprising a hook 1, the bottom of the hook 1 is slidably connected with a movable rod 2, the top of the movable rod 2 extends to the top of the hook 1 and is fixedly connected with an arc-shaped movable block 3, and the arc-shaped The bottom radian of the movable block 3 is adapted to the top radian of the hook 1. The top of the arc-shaped movable block 3 is flat and is provided with an arc-shaped slot 4. The bottom inner wall of the arc-shaped slot 4 is provided with a lanyard placement slot 5. The arc-shaped The top side of the movable block 3 is provided with an installation groove 6, and the interior of the installation groove 6 is rotatably connected with a rotating shaft 8, and two limit rods 9 are symmetrically fixed on the rotating shaft 8, and the other side of the top of the arc-shaped movable block 3 is symmetrical There are two limit slots 7, the installation slot 6 and the two limit slo...

Embodiment 2

[0029]Further improved on the basis of Embodiment 1: the bottom inner wall of the installation groove 6 is penetrated with a transmission rod 11, and the bottom end of the transmission rod 11 extends below the arc-shaped movable block 3 and is fixedly connected with the top side of the hook 1. One side top of the rod 11 is provided with a tooth groove 12, and one side of the rotating shaft 8 is fixedly sleeved with a half gear 13 located between the two limit rods 9, and the half gear 13 is meshed with the tooth groove 12, and when the arc moves When the block 3 moves up and down and drives the half gear 13 to move up and down, the rotating shaft 8 can be driven to rotate through the meshing motion with the tooth groove 12, and the bottom of the arc-shaped movable block 3 is provided with a chute 14 on the side away from the drive rod 11, the chute 14 is slidably connected with a support rod 15, and the bottom end of the support rod 15 extends below the arc-shaped movable block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com