Damping type shear-resistant assembly type beam-column connecting structure

A beam-column connection and shear resistance technology, applied in the direction of earthquake resistance, building components, building types, etc., can solve the problems of easy fracture, weak connection node strength, poor reliability, etc., to reduce stress concentration, simple and convenient installation method, The installation connection is stable and firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

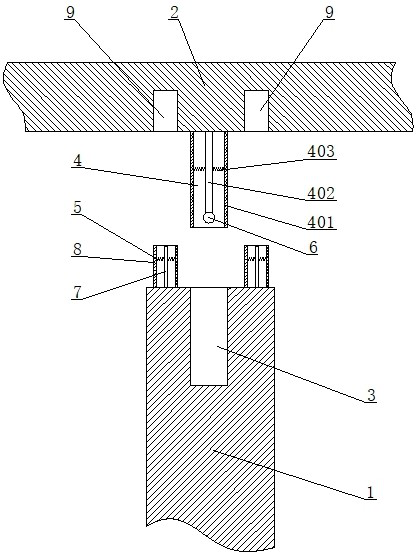

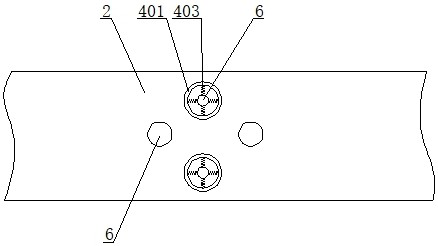

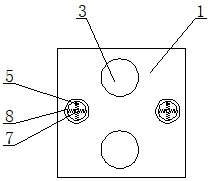

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

[0019] Such as Figure 1-3 As shown, a shock-absorbing shear-resistant assembled beam-column connection structure includes a vertically arranged column 1, a beam 2 arranged horizontally on the top of the column 1, and a horizontally arranged beam 2 on the top of the column 1. 2-4 damping holes 3, two damping holes 3 are set in this embodiment, the column body 1 and the beam body 2 adopt the reinforced concrete structure commonly used in the field of prefabricated buildings, the damping holes 3 are square or circular, in this embodiment In the example, a circular shape is adopted, and the lower surface of the middle part of the beam body 2 is provided with a damping member 4 corresponding to the damping hole 3. The damping member 4 includes a mounting cylinder 401 adapted to the damping hole, and the mounting cylinder 401 is located in the damping hole 3. The mounting cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com