A swash plate driven flow distribution integrated variable displacement plunger pump

A variable plunger and variable piston technology, which is applied in the field of swash plate drive and flow distribution integrated variable plunger pump, can solve the problems of inability to realize variable and large axial size, and achieve simple and compact structure, few rotating parts, and simplified cylinder. body structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

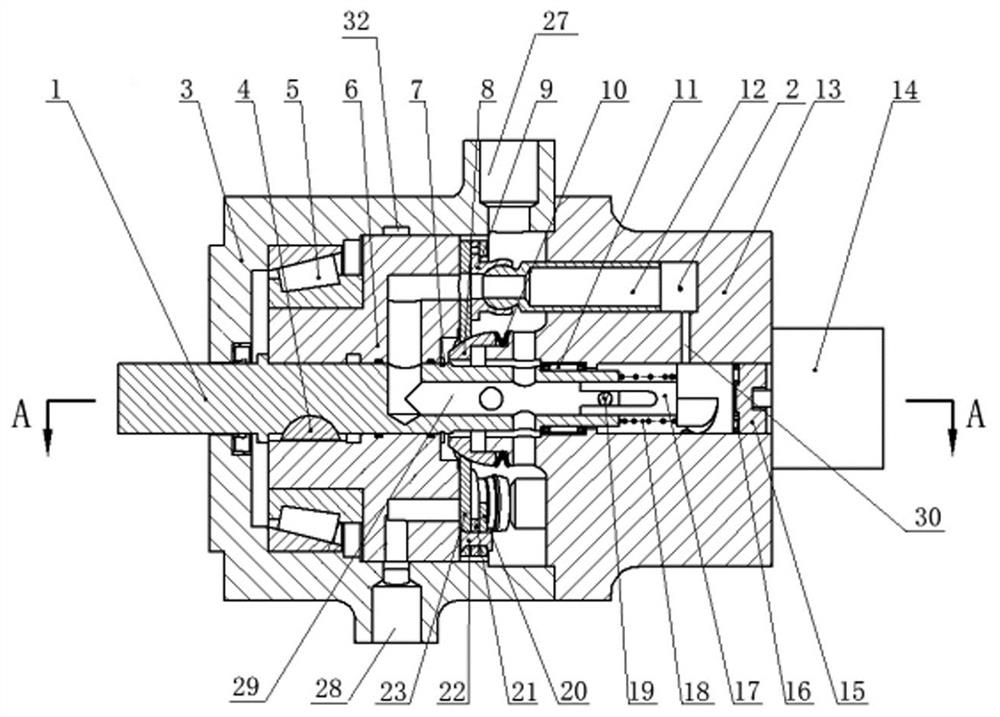

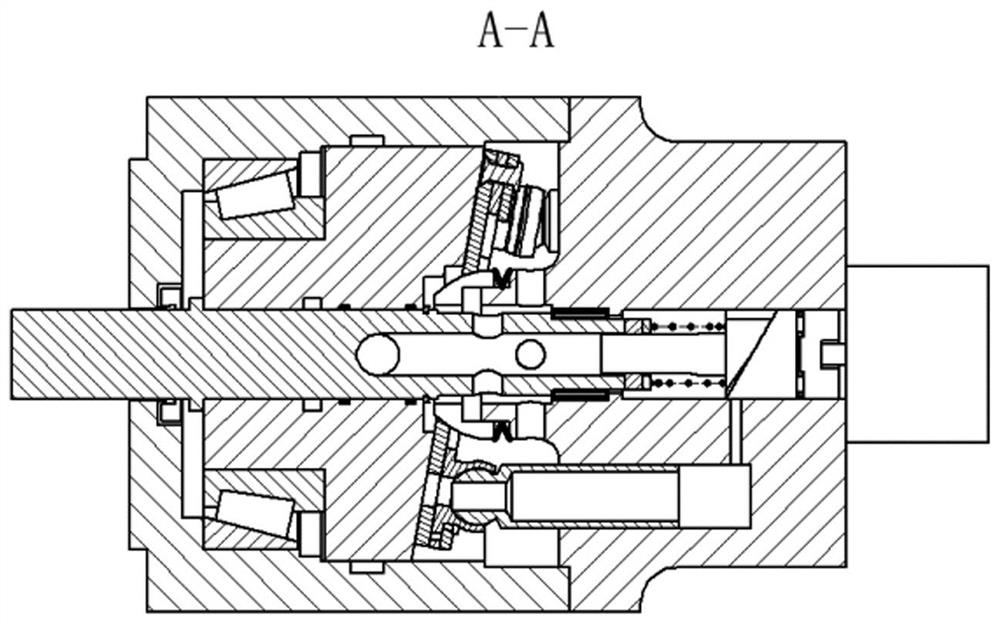

[0044] Such as Figure 1 to Figure 7 As shown, a swash plate driven flow distribution integrated variable displacement plunger pump includes a main shaft 1, a cylinder body 13, a front housing 3, a swash plate 6, a plunger 12, a sliding shoe 9 and a return assembly, the front housing 3 and the cylinder The body 13 is fixedly connected, the swash plate 6 is rotatably arranged in the front housing 3, and the main shaft 1 and the swash plate 6 are connected by a semicircular key;

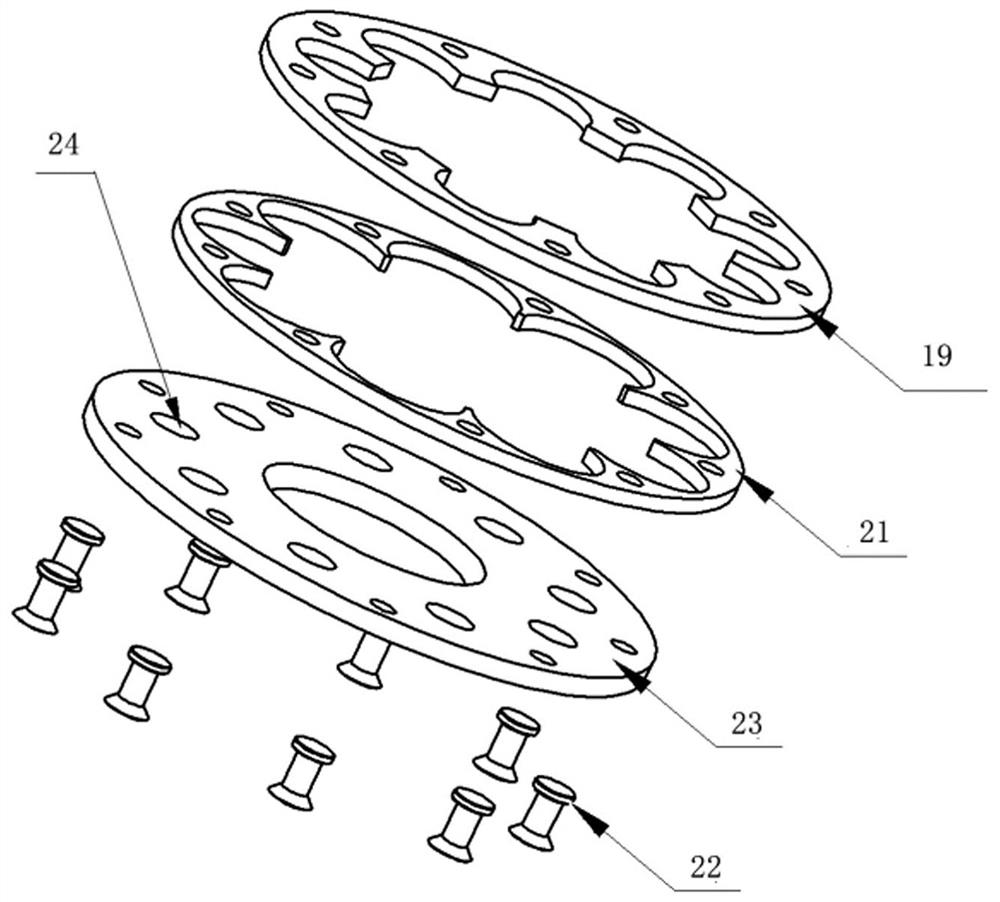

[0045] The end face of the cylinder body 13 opposite to the swash plate 6 is provided with a plunger hole 2, the plunger 12 is slidingly fitted with the plunger hole 2, the sliding shoe 9 is arranged in the return component, and the ball hinge between the plunger 12 and the sliding shoe 9, A plunger shoe assembly is formed, and an oil passage 24 is arranged in the return stroke assembly. One end of the center hole of the plunger of the plunger shoe assembly communicates with the oil passage, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com