Gear shifting method of gear shifting mechanism

A shifting method and technology of shifting mechanism, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problem that the shift lever cannot be kept in the middle position all the time, and the shift lever is easy to generate. Shaking clearance, affecting the service life of the gear shift mechanism, etc., to achieve the effect of improving the handling experience, reliable and reasonable structure design, and strong sense of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

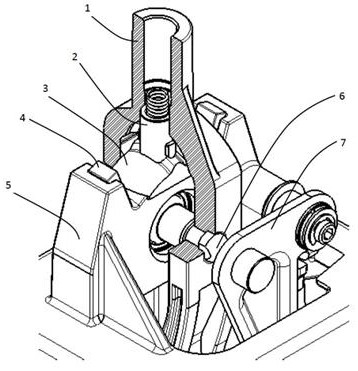

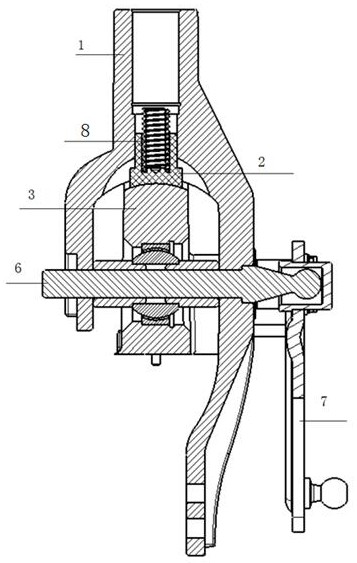

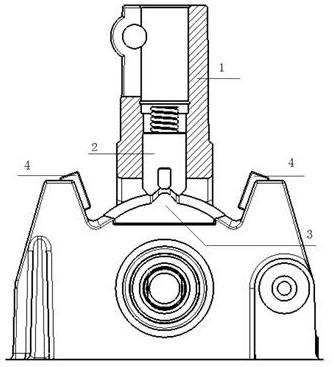

[0040]Combine below Figure 1 to Figure 14 , the present invention is further described:

[0041] A shift mechanism with self-positioning and shift return, comprising a shift lever 1 and a mechanism housing 5, the upper end of the shift lever 1 is connected to the joystick, and the lower end of the shift lever 1 is connected to the flexible shaft of the car. The inner cavity of the gear lever 1 provides the movement space for the slider 2; the slider 2 is located in the inner cavity of the shift lever 1 and can move on the slider seat 3, and the central axis 6 realizes the shift lever 1 and the gear selection rocker 7 The connection with the mechanism housing 5 is characterized in that the slider 2 is provided with a plurality of friction pairs to cooperate with the slider seat 3 to realize the switching of different gears, and to avoid the reduction of the service life caused by concentrated friction.

[0042] The lower end of the slider 2 is a W-shaped structure. The lowerm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Corner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com