Transporting and burying device for burying underground pipelines

A technology for underground pipelines and connecting blocks, which is applied in pipeline laying and maintenance, lifting devices, mechanical equipment, etc., and can solve problems such as inconvenient operation and large effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

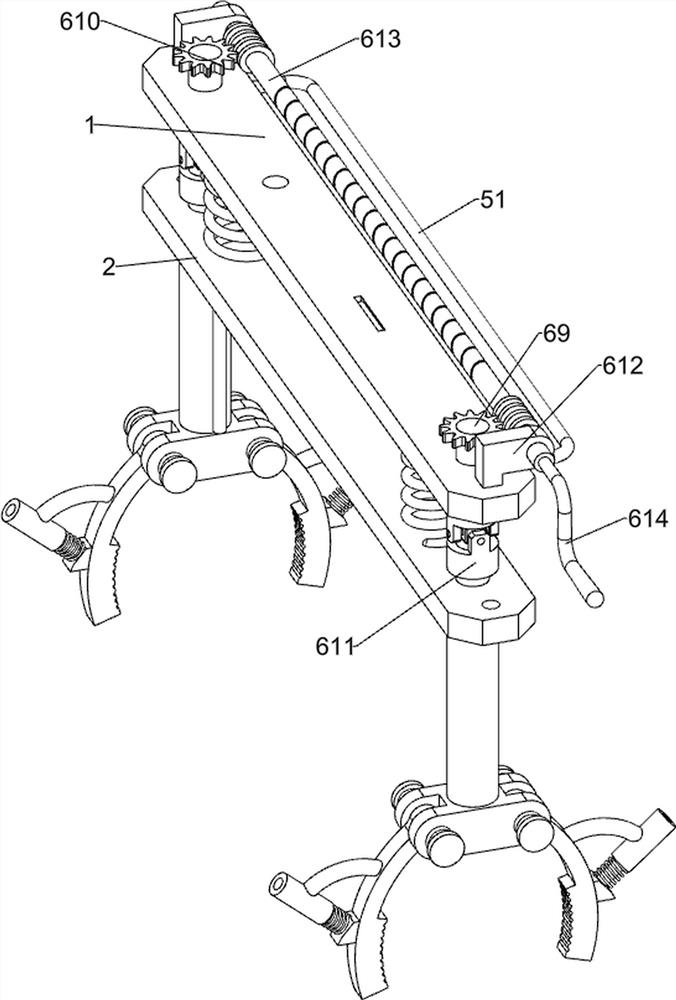

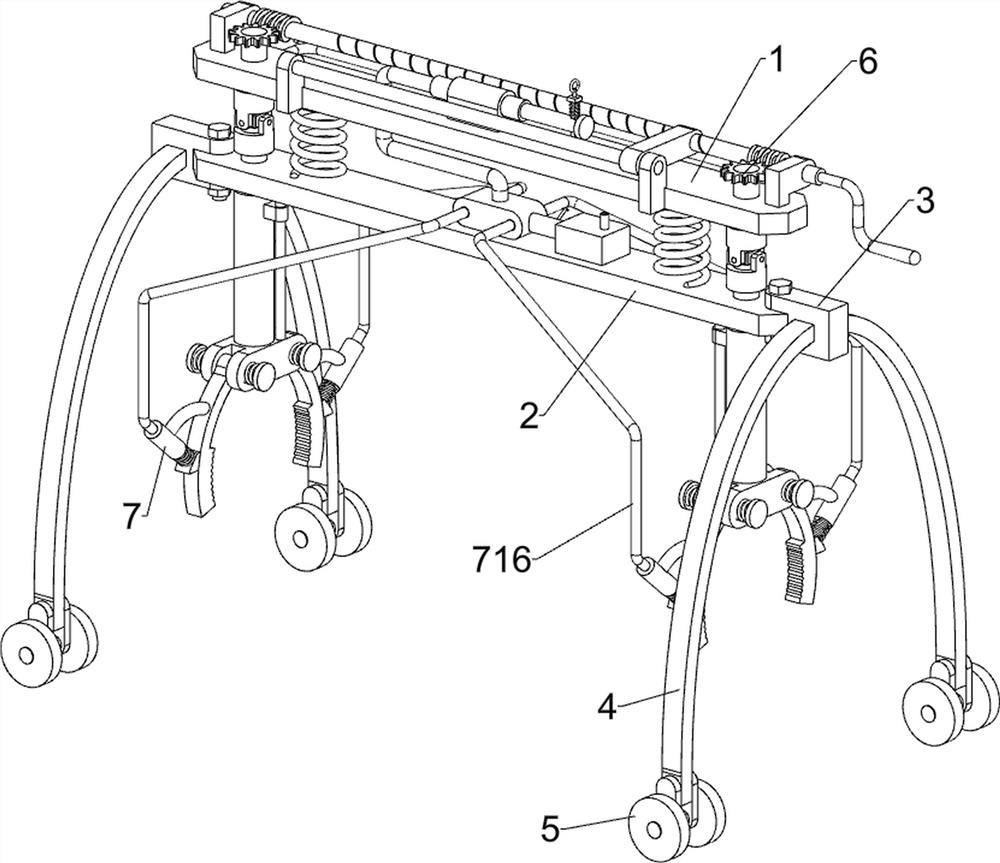

[0022] Such as Figure 1-3 with Figure 5 As shown, a transportation and embedding device for underground pipeline burial includes upper board 1, lower board 2, first connecting block 3, bent rod 4, wheels 5, handle 51, lowering and raising mechanism 6 and hydraulic pushing mechanism 7. There is a lower board 2 under the upper board 1 and a slot and a square hole are opened on the upper right side of the upper board 1. The first connecting block 3 is arranged at both ends of the lower board 2, and the first connecting block 3 is two Both sides are provided with curved rods 4, and the lower ends of the curved rods 4 are provided with wheels 5, and the rear side of the upper board 1 is provided with a handle 51, and the upper board 1 is provided with a descending mechanism 6, and the upper board 1 and the lower board 2 A hydraulic push mechanism 7 is arranged between them.

[0023] The descending and ascending mechanism 6 includes a screw mandrel 61, a threaded cylinder 62, a ...

Embodiment 2

[0027] Such as Figure 4 As shown, on the basis of Embodiment 1, a transportation and embedding device for underground pipeline embedding also includes a second fixing base 8, a second guide post 9 and a nut block 10, and the upper front side of the upper vehicle plate 1 is about the upper The center line of the car plate 1 is symmetrically provided with a second fixed seat 8, and a second guide post 9 is arranged between the second fixed seats 8, and a nut block 10 is slidably arranged on the second guide post 9, and the rear side of the nut block 10 is connected to the transmission shaft. 613 central thread fits.

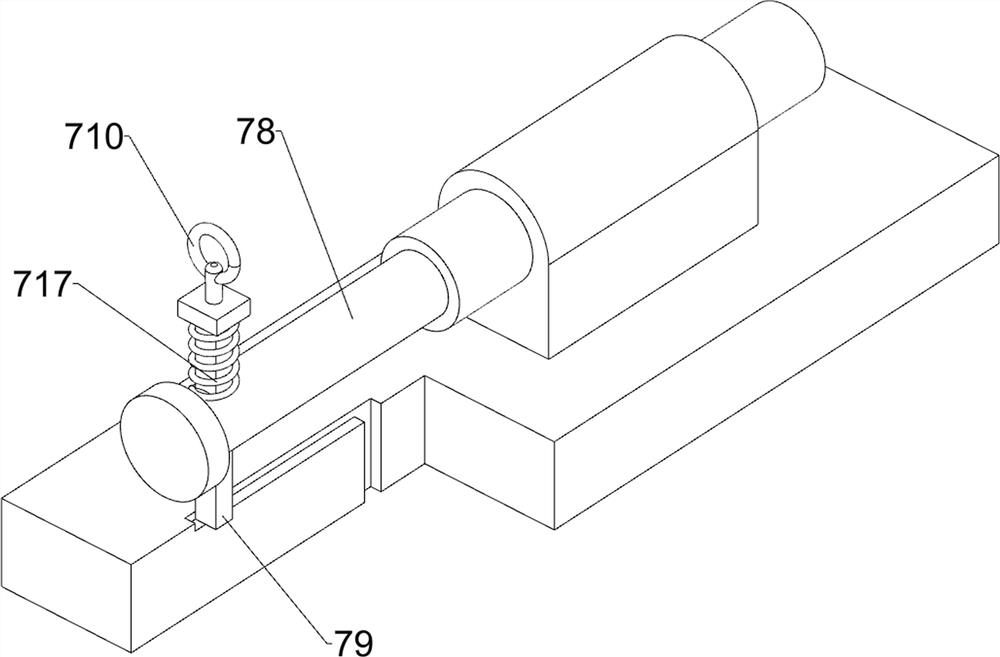

[0028] In the process of rotating the transmission shaft 613, the rotation of the transmission shaft 613 will cause the nut block 10 to move in the direction close to the second piston rod 78 on the second guide post 9, and when the nut block 10 moves a certain distance, the nut block 10 will push the first Two piston rods 78 squeeze the hydraulic oil in the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com