Vehicle tire testing system with elastic supporting framework body

A test system and elastic support technology, applied in the direction of automobile tire test, vehicle test, machine/structural component test, etc., can solve the problems of small detection range and single function, and achieve low production cost, sound function and convenience. Check the effect of the job

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

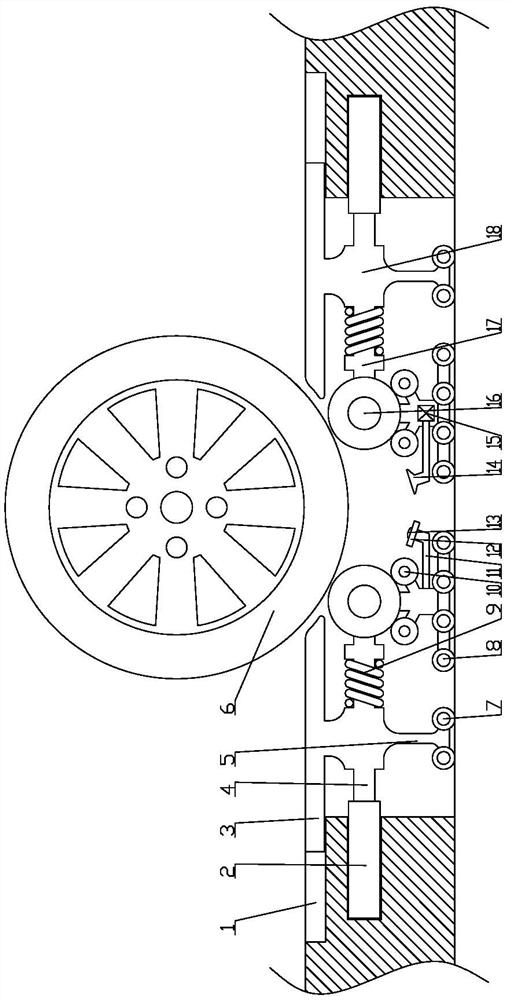

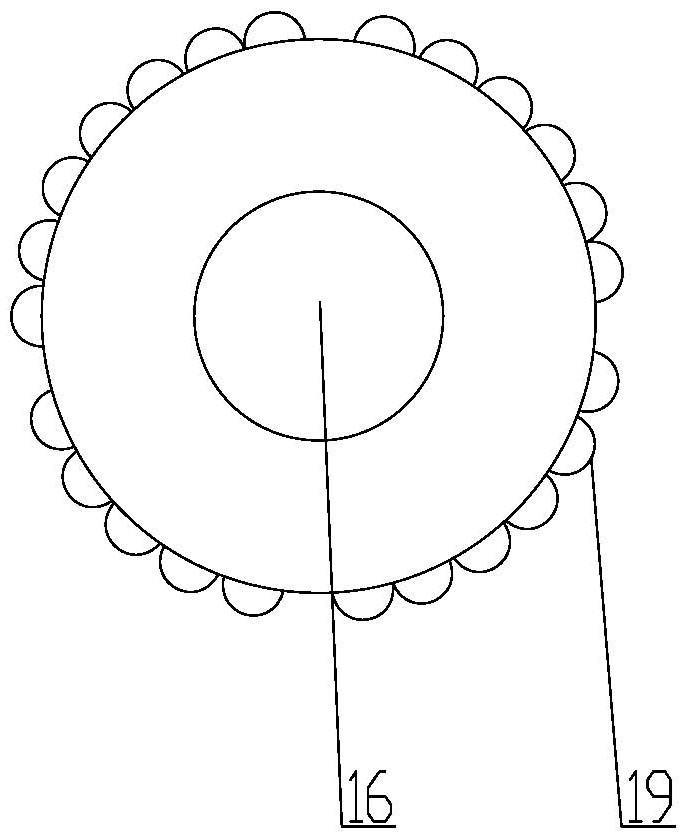

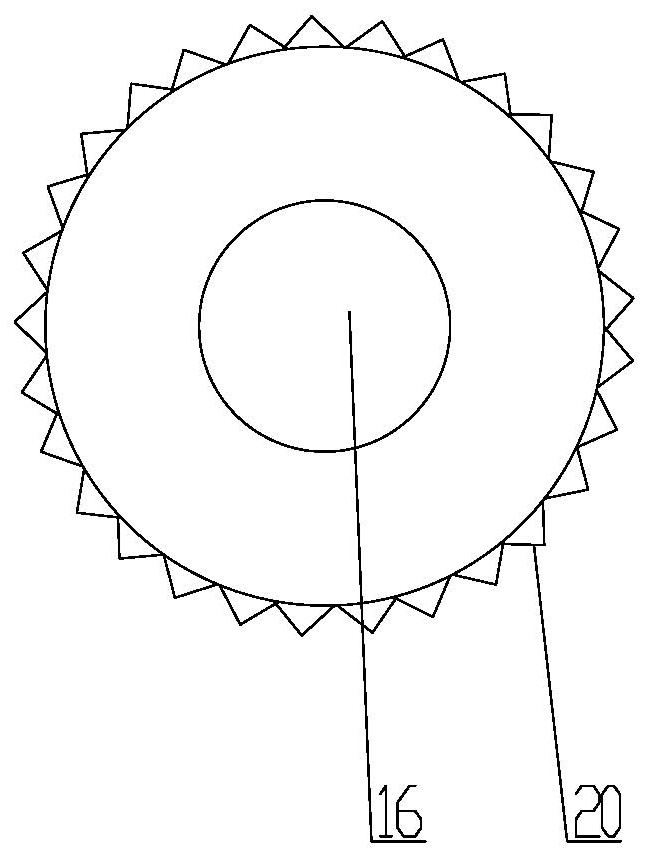

[0019] like figure 1 As shown, a vehicle tire testing system with an elastic support frame body is characterized in that a ground cavity, the two sides of the inner wall of the ground cavity are relatively provided with a transverse cavity, and a first cylinder and a second cylinder are arranged in the transverse light body; Both sides of the ground cavity are provided with telescopic chambers; the first cylinder and the second cylinder are respectively provided with a first extension arm and a second extension arm; the first extension arm and the second extension arm are respectively provided with a first roller and a second extension arm. Two rollers.

[0020] Wherein the first extension arm and the second extension arm are equally divided into the first forearm, the first rear arm, the second forearm and the second rear arm; the first support spring is arranged between the first forearm and the first rear arm; the second A second support spring is arranged between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com