Method for controlling boundary layer of slender revolving body to keep laminar flow flowing without separation

A technology of rotating body and boundary layer, which is applied in the direction of hull design, sustainable transportation, complex mathematical operations, etc., and can solve problems such as increasing the frictional resistance of the sailing body, increasing the pressure difference resistance, and increasing the drag of the sailing body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below with reference to the accompanying drawings and examples.

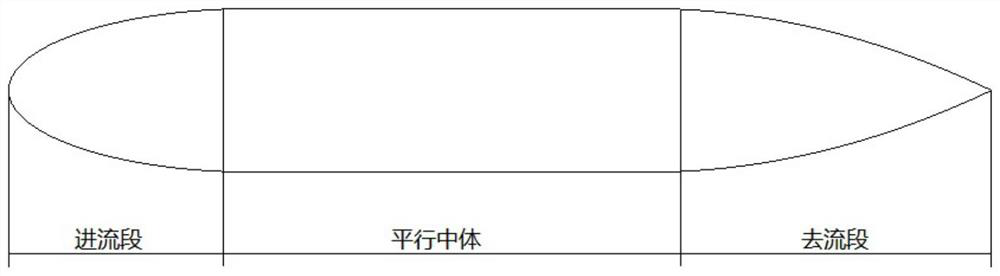

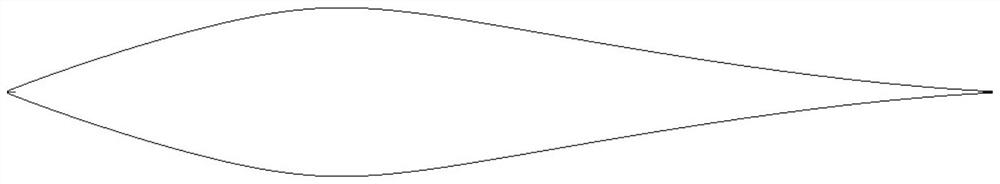

[0062] This embodiment provides a method for controlling the boundary layer of an elongated rotating body to maintain laminar non-separated flow. By optimizing the shape and surface characteristics of the elongated rotating body, the elongated rotating body can maintain laminar flow within a set speed range , to avoid flow separation or transition on the surface of the slender rotating body.

[0063] The method includes the following steps:

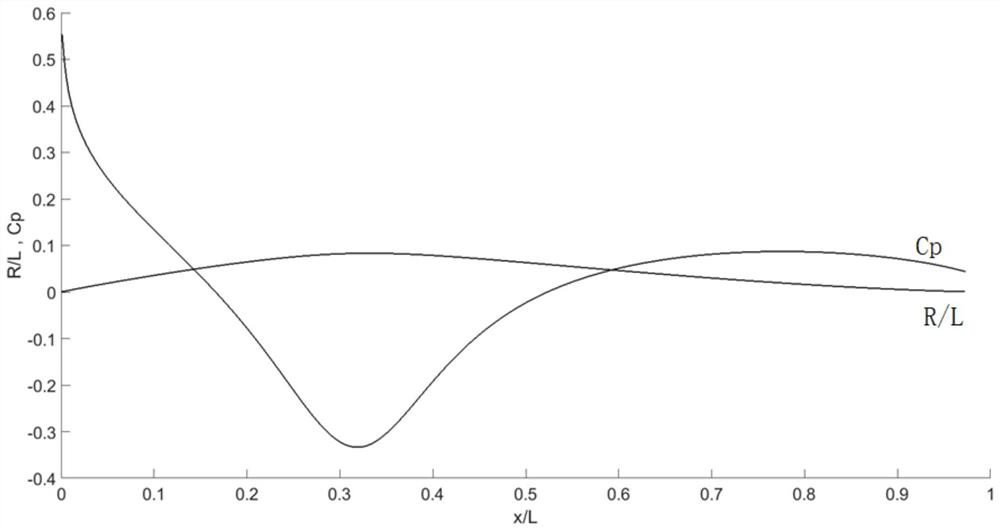

[0064] Step 1: Preset the length, slenderness ratio (take the larger value) and speed index of the slender rotating body, and obtain the potential flow equation of the surface flow field of the slender rotating body according to the slender body theory and the potential flow theory;

[0065] Specifically: because the two conditions for fluid flow separation are: (1) the fluid is viscous; (2) there is a reverse pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com