Image sensor assembly and camera assembly

An image sensor and component technology, applied in image communication, electrical components, telephone structure, etc., can solve the problem of terminal equipment losing the anti-shake function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

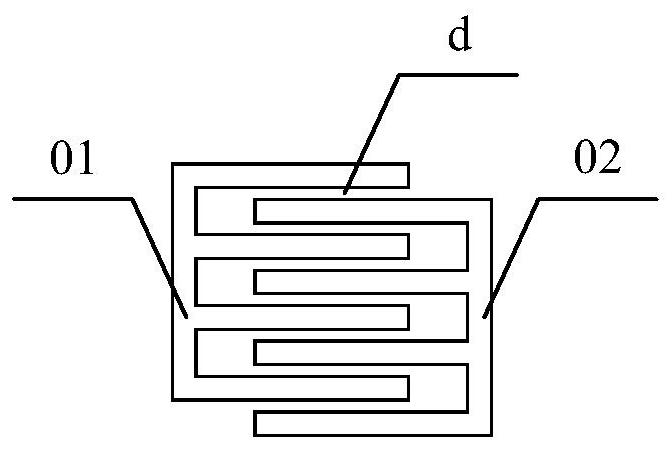

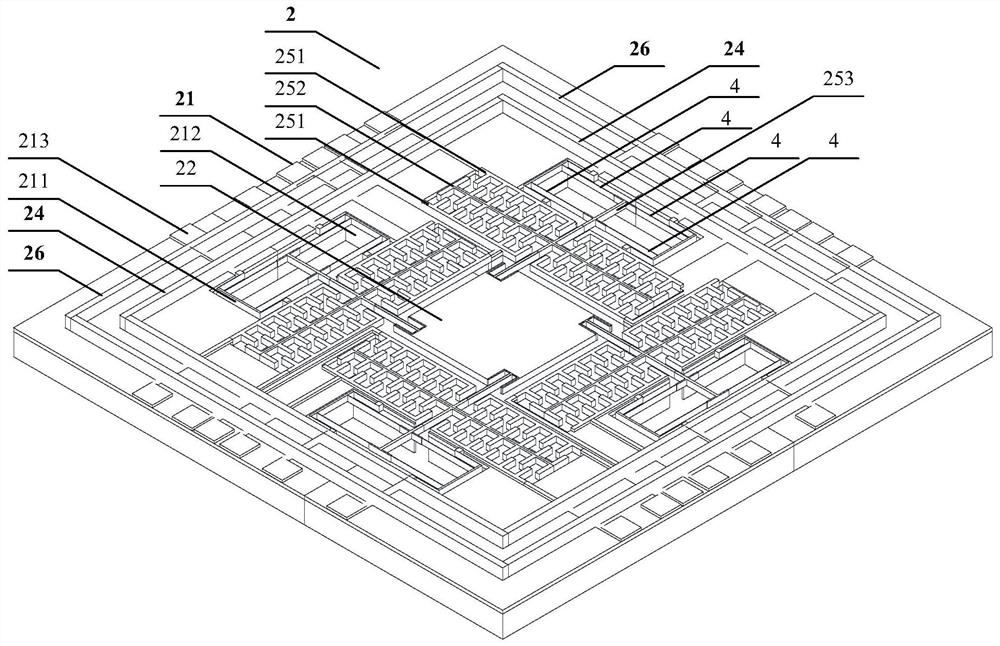

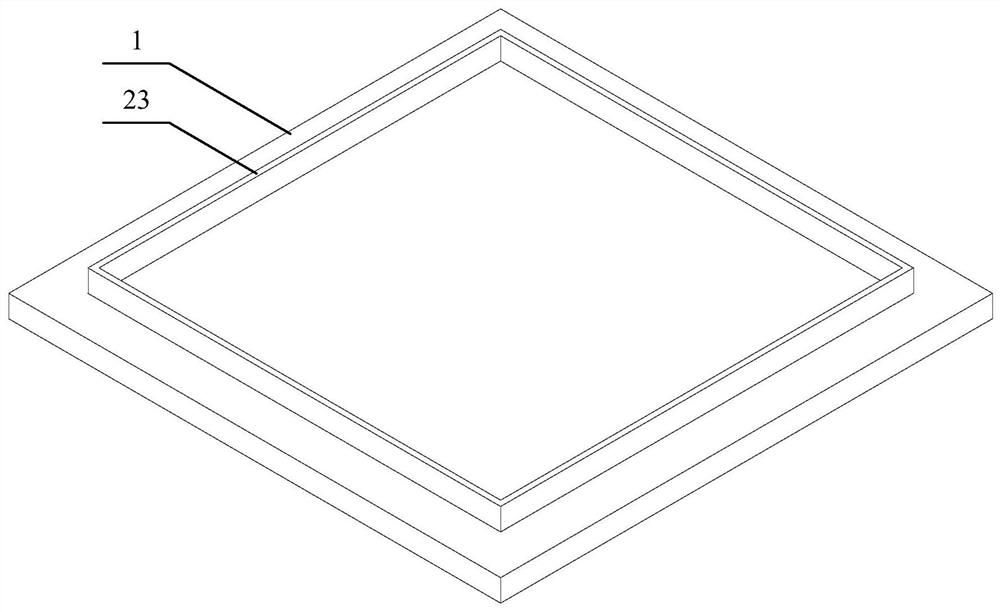

[0080] An embodiment of the present application provides an image sensor component, which can be applied to a terminal device with a camera function, for example, can be applied to a mobile phone, a tablet computer, a digital camera, etc., in order to realize the miniaturization of the image sensor component , in order to reduce the installation space on the terminal equipment, when processing image sensor components, it can be based on MEMS (Micro-Electro-Mechanical System, micro-electro-mechanical system) manufacturing technology, where MEMS manufacturing technology is developed in semiconductor manufacturing technology, The size of structures processed by MEMS manufacturing technology is generally in the order of microns or even submicrons. Therefore, by applying MEMS manufacturing technology to image sensor components, the processed image sensor components are smaller in size and more compact in structure. Of course, this embodiment is not limited to the specific processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com