Positioning placement structure of separation assembly

A technology of components and partitions, which is applied to furniture parts, household appliances, drawers, etc., can solve problems such as inability to position and complex structure of partition components, achieve convenient storage and transportation, improve internal space utilization, and quickly disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

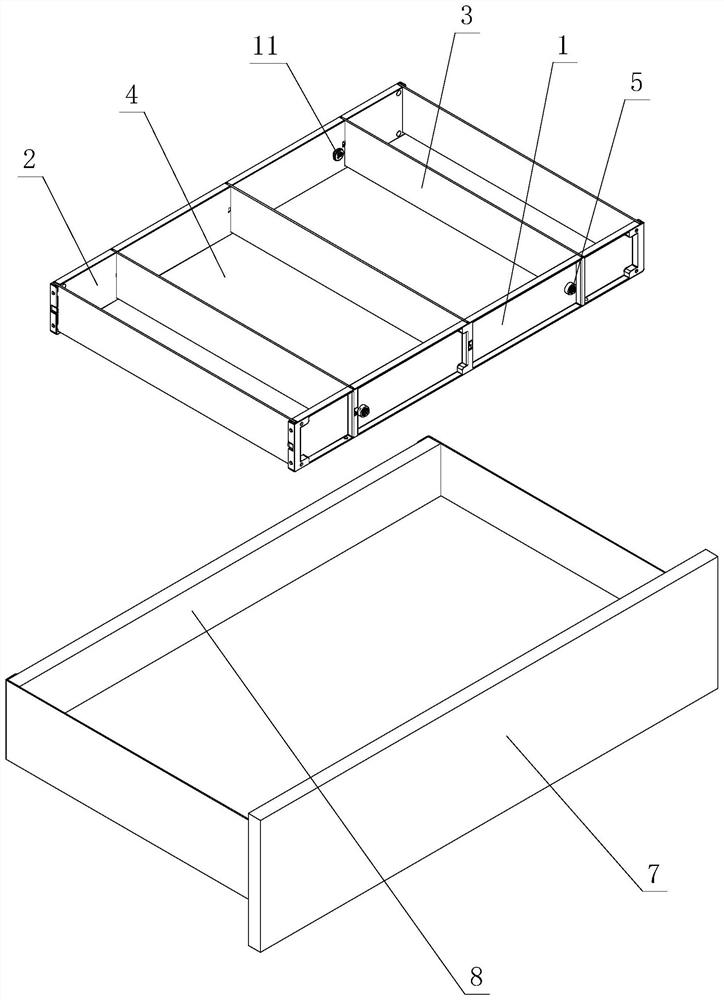

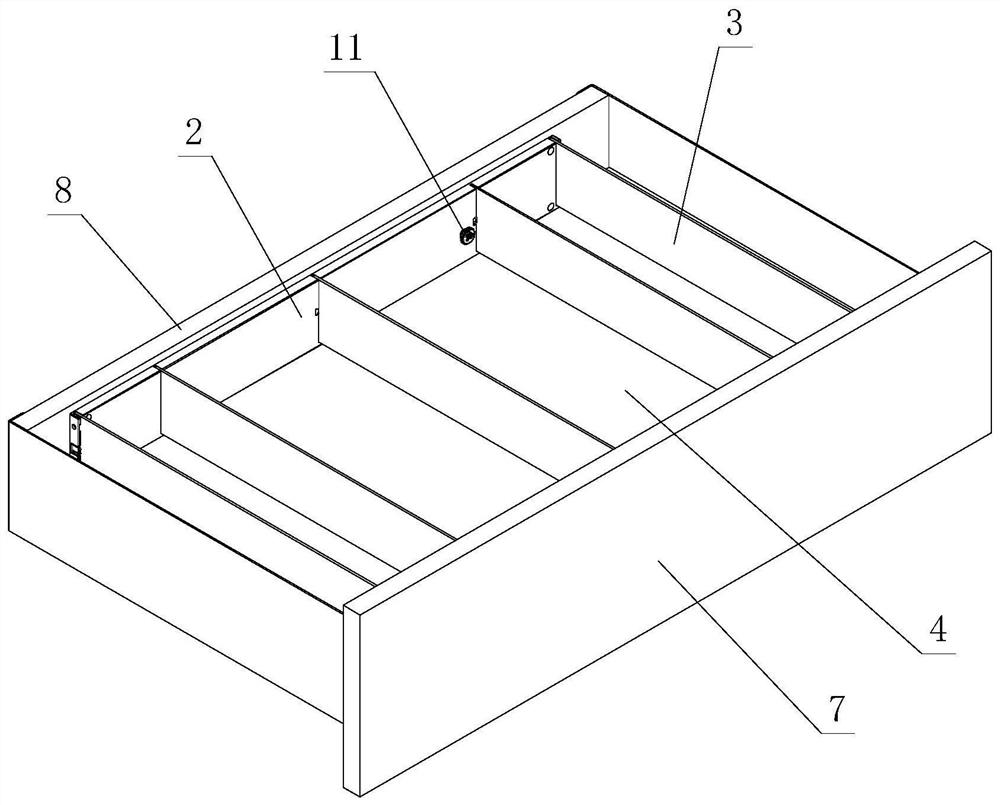

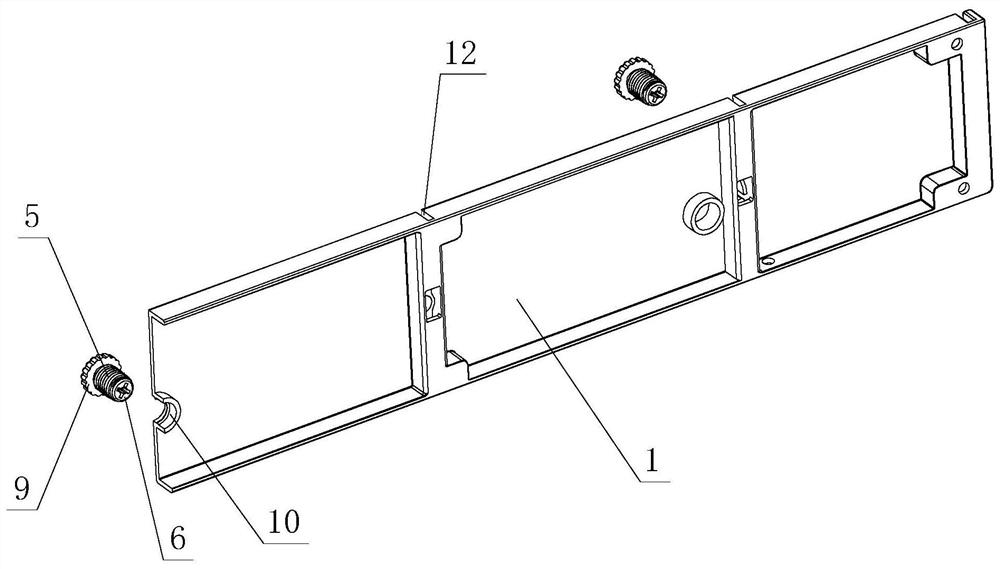

[0031] see Figure 1-Figure 7 , the positioning and placement structure of the partition assembly, the partition assembly includes a front partition 1 and a rear partition 2, the front partition 1 and the rear partition 2 are flat plates, and are detachably provided with partitions. The plate 3, the front partition 1, the rear partition 2, and the partition 3 form at least one separate storage chamber 4; wherein, the front partition 1 and / or the rear partition 2 are provided with a protruding part 5, the convex The extension part 5 is telescopically movable on the outside of the front partition 1 and / or the rear partition 2, and protrudes from the outer end surface of the front partition 1 and / or the rear partition 2 at least when stretching out.

[0032] Specifically, the protruding part 5 can be adjusted and stretched on the outside of the front bulkhead 1 and / or the rear bulkhead 2, or the protruding part 5 can be elastically or plastically telescopic and movable on the fro...

no. 2 example

[0041] see Figure 8-Figure 10 , the positioning and placement structure of this partition assembly is different from the first embodiment in that: the protruding part 5 is at least made of a material with certain elasticity or plastic, and is integrally or separately arranged on the front bulkhead 1 and / or Or the outer side of the rear bulkhead 2, and its outer end surface is provided with a limited positioning 6; wherein, the protrusion 5 can be elastically or plastically telescopically movable on the outer side of the front bulkhead 1 and / or the rear bulkhead 2, and at least pass through the limit when extending out. The outer end faces of the bits 6 and the transverse inner end faces of the front plate 7 and / or the rear plate 8 abut against each other.

[0042] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com