Ship propeller self-cleaning device

A cleaning device and propeller technology, applied in the field of ships, can solve the problems of low efficiency, potential safety hazards, and high cost, and achieve the effects of improving cleaning efficiency, reducing potential safety hazards, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

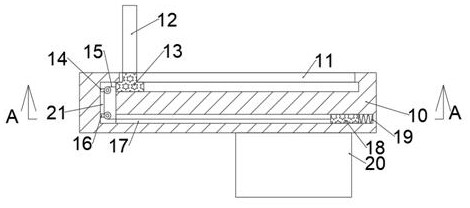

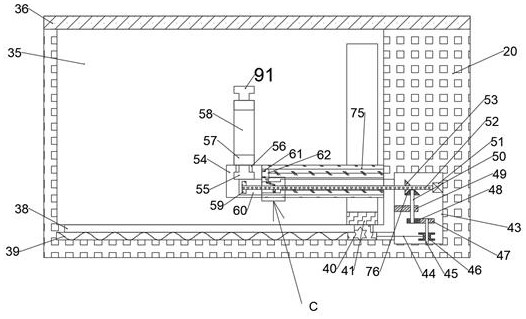

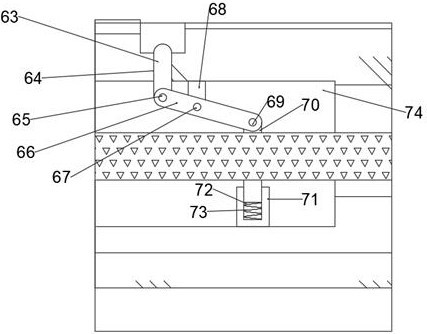

[0014] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0015] combined with Figure 1-4 The self-cleaning device for a ship's propeller includes a support plate 10, the support plate 10 is provided with a first chute cavity 11 with an upward opening, and the support plate 10 is provided with a second sliding chute with an opening backward. Groove cavity 17, the inner wall on the upper side of the second chute cavity 17 is provided with a first communication cavity 21 communicating with the first chute cavity 11, and a cleaning box 20 is provided on the rear side of the support plate 10 , the cleaning box 20 is provided with a first working cavity 35 with an upward opening, and the first working cavity 35 is provided with a locking device...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap