Wood industry dust removal system

A dust removal system and wood industry technology, applied in wood processing equipment, bark area/debris/dust/waste removal, filtration and separation, etc., can solve the problems of inability to handle fan blades, unfavorable efficiency, and more labor and time costs and other problems, to achieve good dust collection effect, ensure cleanliness, and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: See Figure 1-5 , the present invention provides a technical solution:

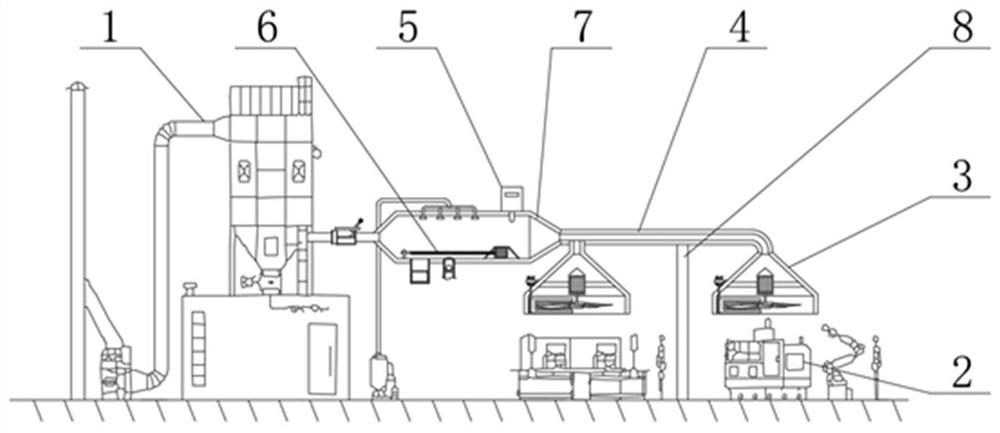

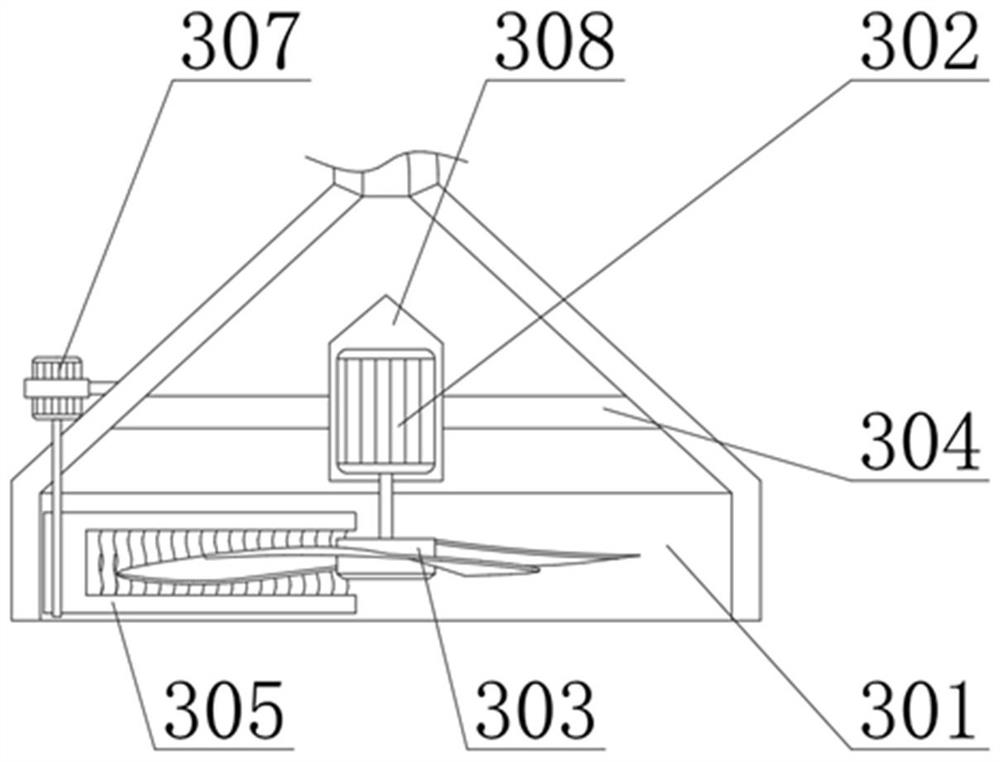

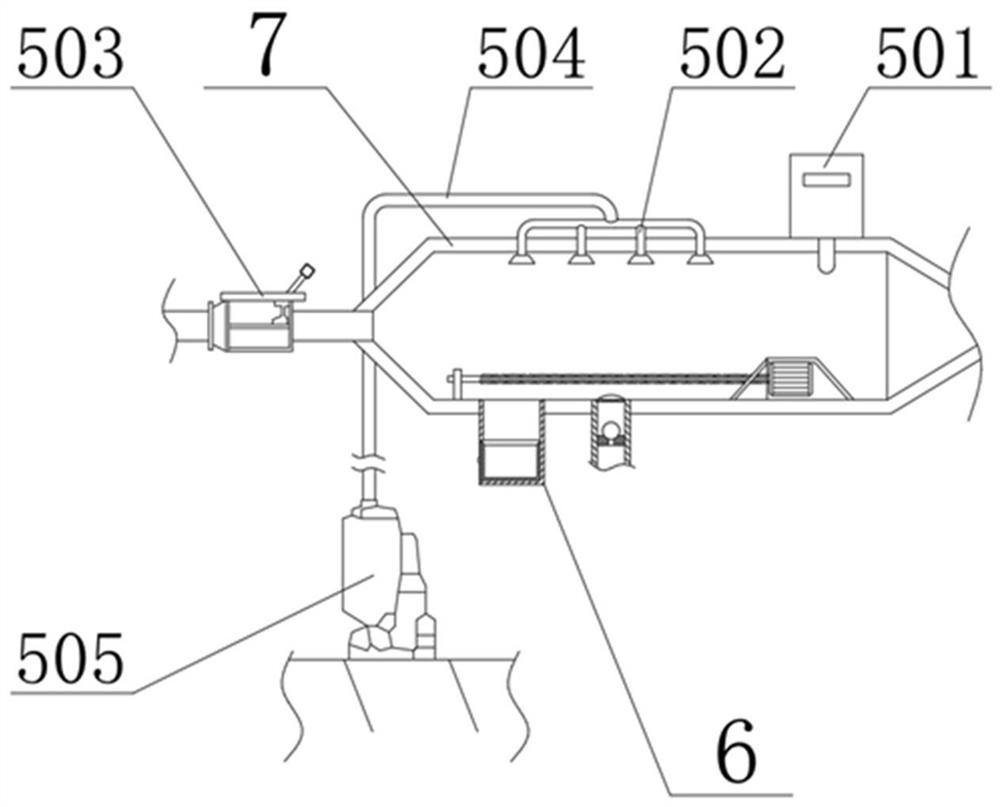

[0024] A wood industry dust removal system, including a dust removal mechanism 1, a workbench 2, a dust suction device 3, a connecting pipe 4, a spark detection and alarm extinguishing system 5, and a cleaning device 6. A dust suction device 3 is provided directly above the workbench 2 to absorb The top of the dust device 3 is connected to a connecting pipe 4, and the other end of the connecting pipe 4 is connected to a processing box 7. A support rod 8 is installed at the center of the bottom end of the connecting pipe 4, and a spark detection alarm extinguishing system is installed on the top of the processing box 7. 5. The bottom end of the processing box 7 is equipped with a cleaning device 6, and the other side of the processing box 7 is connected to the dust removal mechanism 1 through a pipeline. The bottom end surfaces of the support rods 8 are all fixedly connected to the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com