Tray plastic suction mold

A technology of plastic-absorbing molds and trays, which is applied to household appliances, other household appliances, household components, etc. It can solve the problems of low demoulding efficiency, affecting the tray production pass rate, and damage to the outer edge of the tray, so as to improve the demoulding efficiency , Demoulding is convenient and fast, and the effect of improving the production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

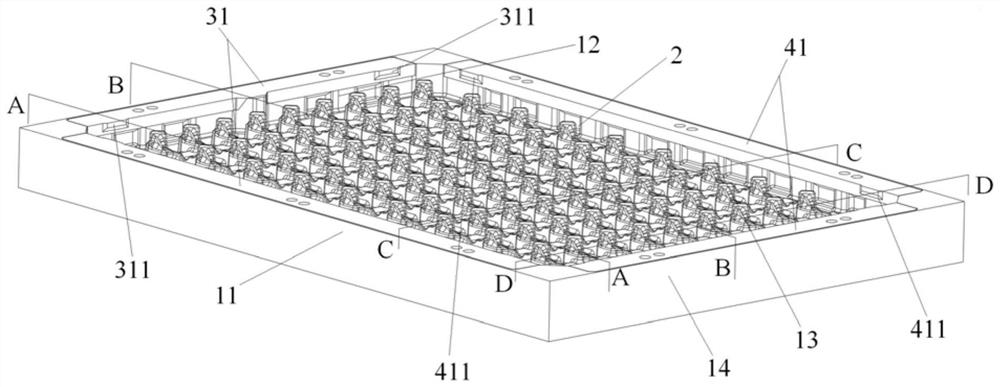

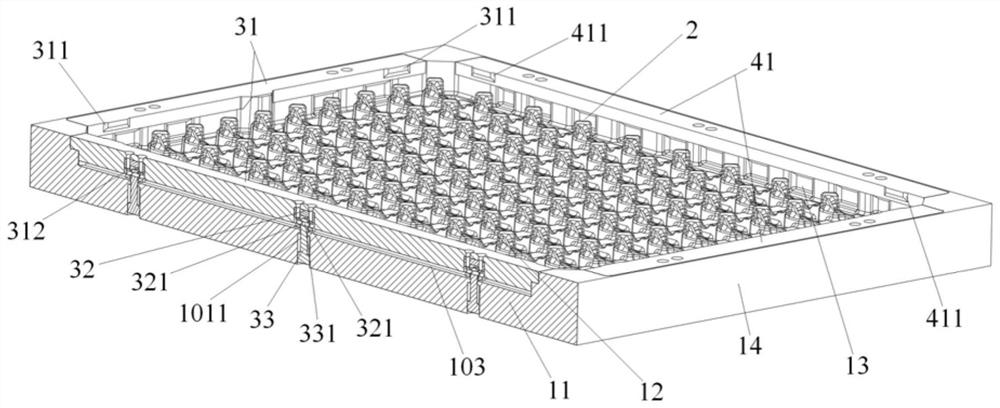

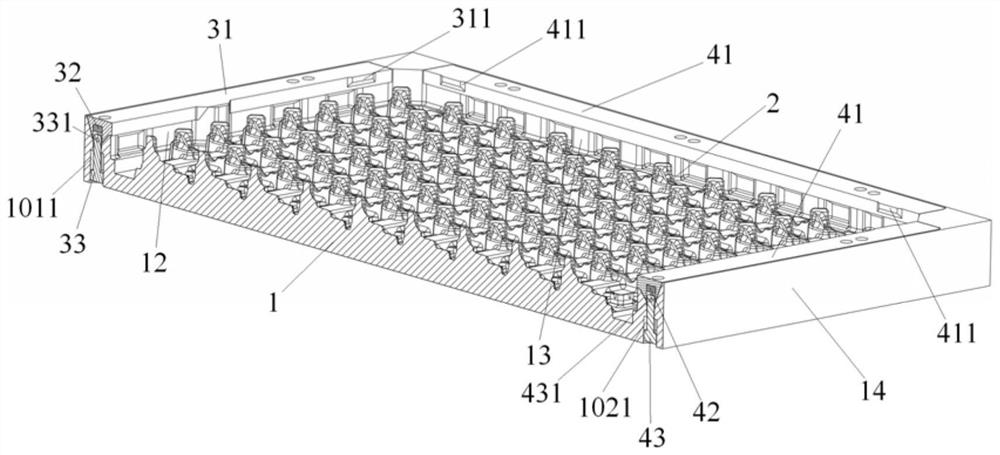

[0016] Below, combine Figure 1-5 The tray blister mold of the present invention is described in detail.

[0017] Such as Figure 1-5 As shown, the tray blister mold of the present invention includes a bottom plate 1 and a mold core 2, the mold core 2 is located on the bottom plate 1, a rectangular convex frame is arranged around the mold core 2, and the adjacent first side frame 11 and the second side frame in the rectangular convex frame Both side frames 12 are provided with first demoulding mechanisms, and adjacent third side frames 13 and fourth side frames 14 are provided with second demoulding mechanisms. Wherein, the first demoulding mechanism comprises a first flipping plate 31, which is located on the top of the rectangular convex frame and is connected with the first connection in the first connecting sliding hole on the rectangular convex frame through the first connecting block 32. The sliding posts 33 are connected, and the first connecting sliding posts 33 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com