A soft and hard heterogeneous conveyor belt guide film

A conveyor belt and guide film technology, which is applied to other household appliances, synthetic resin layered products, and winding strips, etc., can solve the problems of soft conveyor belt variability, damage to the knife mold, and reduce the service life of the knife mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

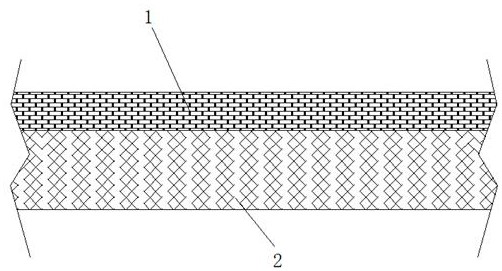

[0031] see figure 1 , a kind of soft and hard heterogeneous conveyor belt guide film, including a base film 2 and a surface film 1, the surface film 1 and the base film 2 are composited, the base film 2 is a hard film, and the surface film 1 for soft membranes.

[0032] Preferably, the bottom film 2 is made of hard material, and the hard material is biaxially stretched PET, ABS, or stainless steel belt.

[0033] Preferably, the surface film 1 is made of soft material, and the soft material is PVC, EVA, PE, PU, PO, PA, soft polyester.

Embodiment 2

[0035] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

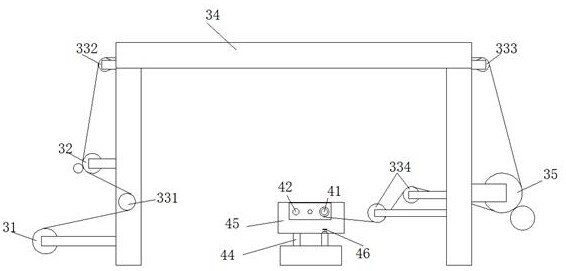

[0036] see Figure 2-6 ; The preparation method of the soft and hard heterogeneous conveyor belt guide film comprises the following steps:

[0037] (1) Place the bottom film 2 on the unwinding roller 31, place the surface film 1 on the composite roller 35, and make the bottom film 2 on the unwinding roller 31 flow to the glue roller 32 through the first guide roller 331 On, apply glue evenly on the surface of the base film 2;

[0038] (2) The bottom film 2 coated with glue is guided into the drying box 34 by the second guide roller 332 for baking;

[0039] (3) After the baking is completed, the third guide roller 333 guides the flow to the compound roller 35, so that the surface film 1 is compounded on the bottom film 2;

[0040] (4) Guide the laminated film to the fast winding mechanism through the fourth guide roller 334 for fast winding.

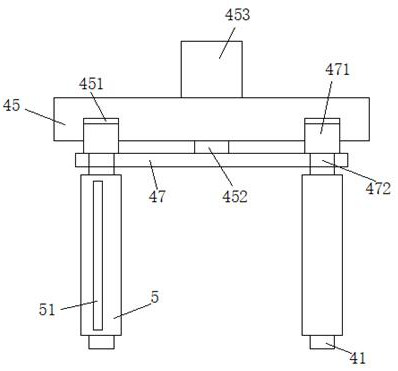

[0041] Further, the fast winding mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com