Driving wheel and AGV

A technology for driving wheels and hubs, applied in the direction of brakes, motion deposition, power devices, etc., can solve problems such as difficult to ensure high transmission ratio and high transmission torque, large braking torque demand, increased volume, etc., to achieve small size, deceleration The effect of large ratio and transmission torque and high transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

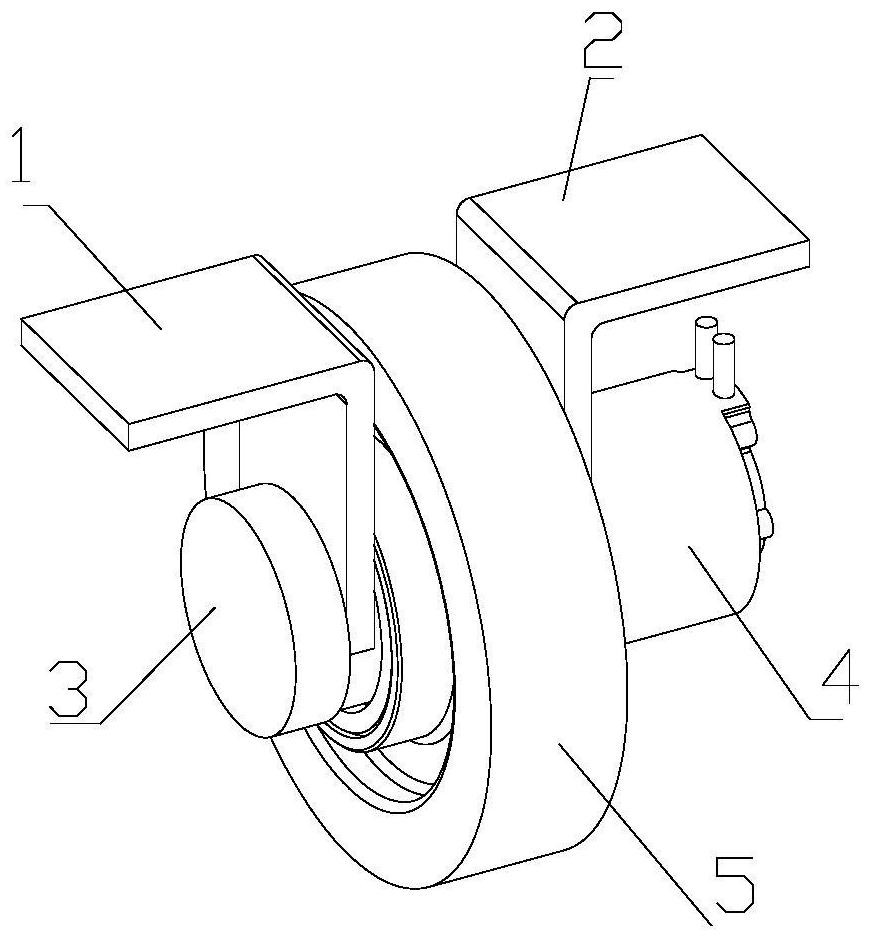

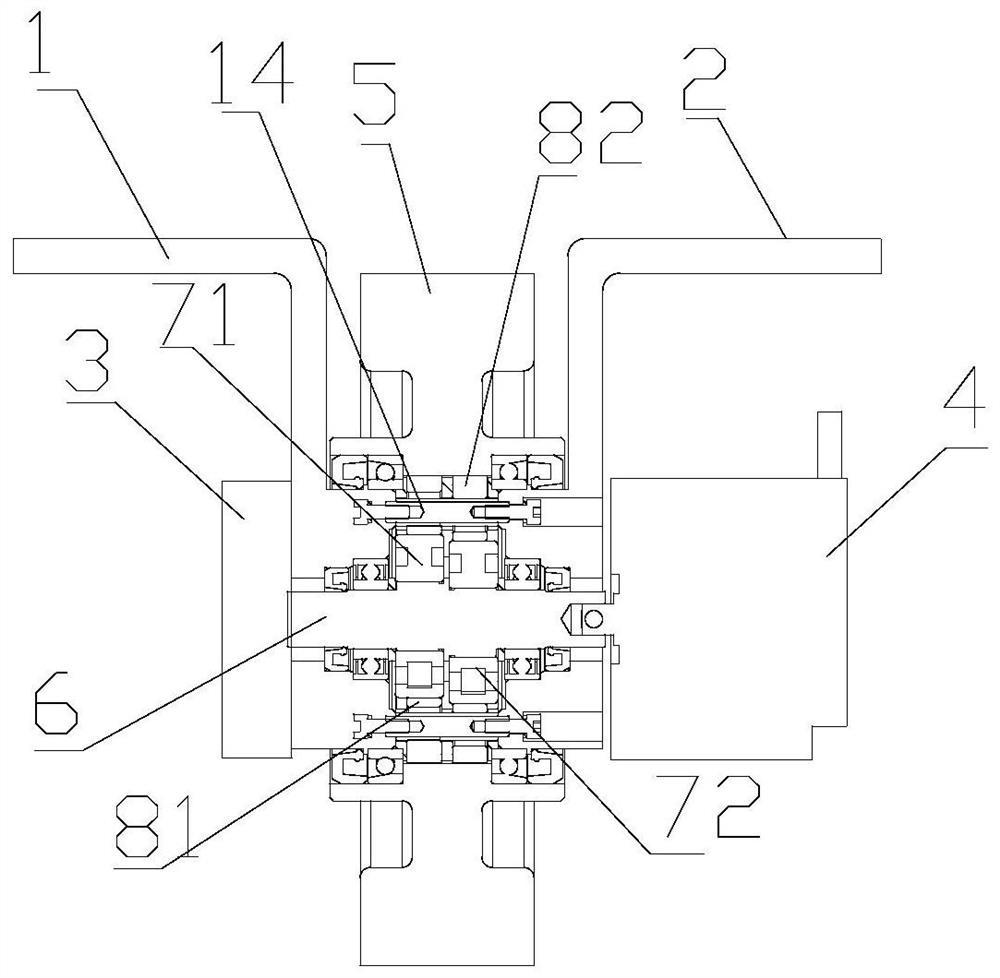

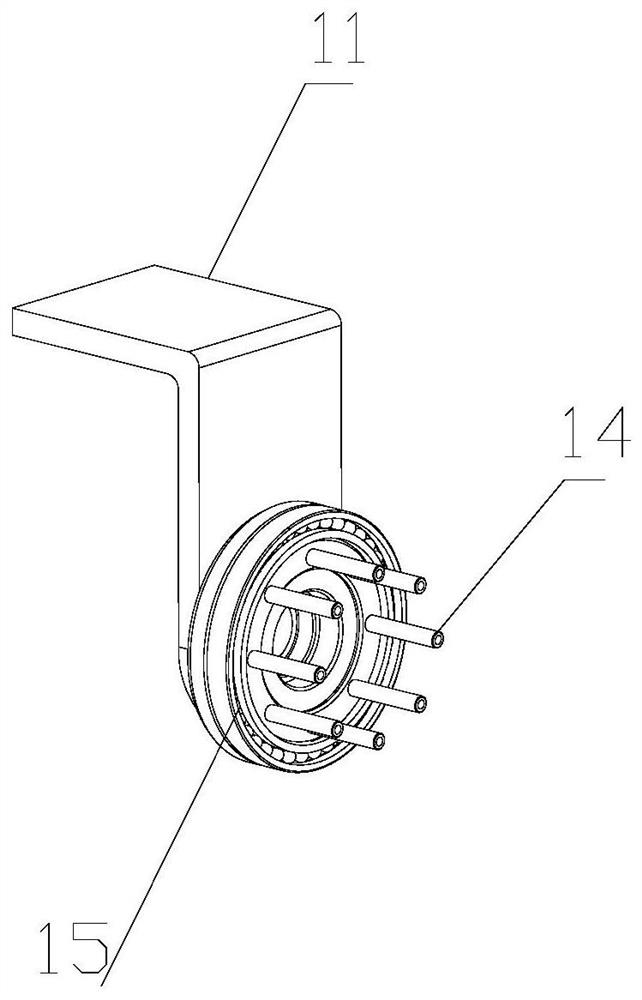

[0029] Such as figure 1 with 2 As shown, the present invention provides a kind of drive wheel, and described drive wheel comprises input shaft 6, and described input shaft 6 has a plurality of eccentric structures, and external gear is installed on each eccentric structure, and described external gear casing A wheel hub 5 is provided, and the inner side of the wheel hub 5 is provided with a ring of internal teeth 53 capable of meshing with the external teeth of the external gear, and the drive wheel also includes a bracket assembly, and the bracket assembly includes a plurality of pin shafts 14. The external gear is provided with a plurality of circumferentially distributed pin h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap