Multilateral synchronous film coating device

A technology for synchronous wrapping and filming devices, applied in packaging, wrapping paper bending devices, transportation and packaging, etc., can solve the problems of affecting the wrapping processing efficiency, many equipment parts, and occupying a large space, so as to improve the wrapping processing efficiency, Good synchronization and simplified device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

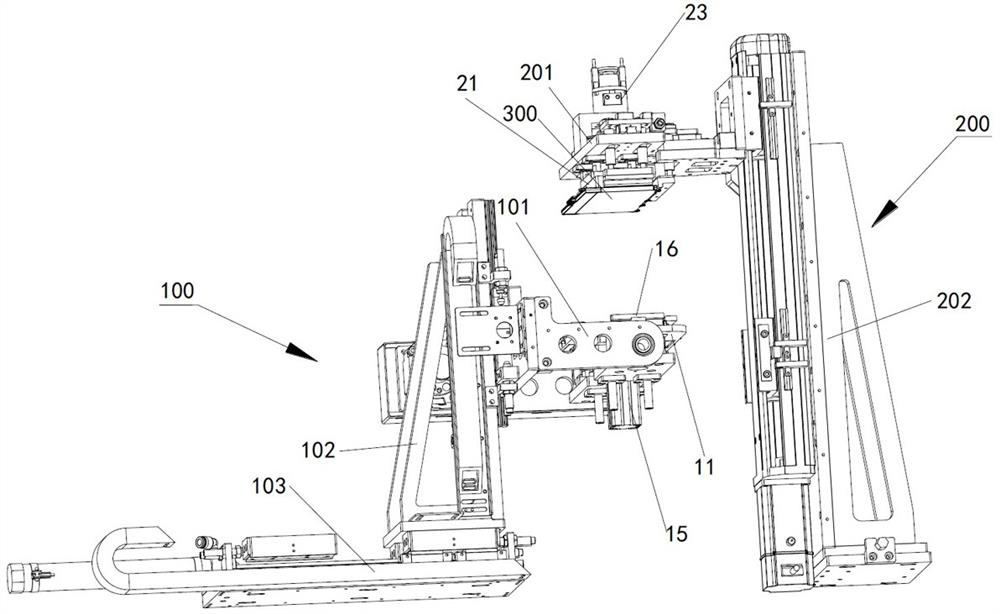

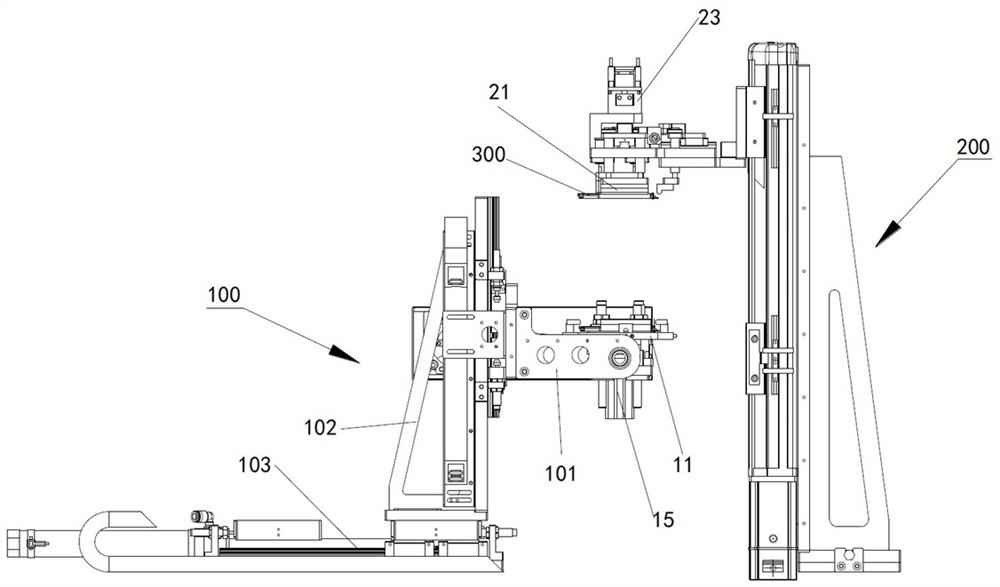

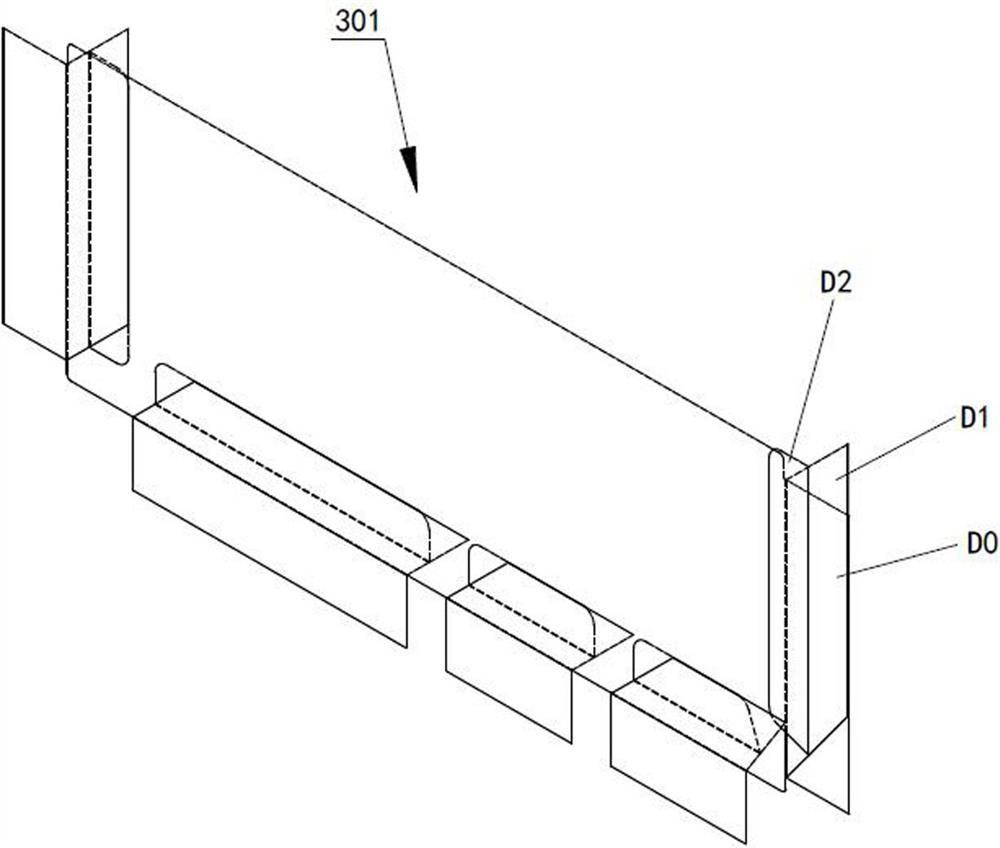

[0037] see Figure 1 to Figure 18 As shown, an automatic coating machine, the product 300 to be coated is in the shape of a thin plate, which has a top surface and a bottom surface opposite to each other, and two first sides and two second sides located between the top surface and the bottom surface and opposite to each other. Two sides, the coating process requires that the bottom surface of the product 300 to be coated is coated with a film 301, and the film 301 is coated on multiple sides of the product 300 to be coated and then coated on the top surface.

[0038] The automatic coating machine includes:

[0039] Conveying device (not shown in the figure), is used for conveying product 300 to be coated, the bottom surface of this product 300 to be coated is coated with film 301, and keeps the bottom face upwards an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap