Tank bottom supporting structure for tank transportation and working method of tank bottom supporting structure

A technology of supporting structure and working method, which is applied in the direction of transportation and packaging, containers, packaging, etc., and can solve problems such as tank displacement, collision, and tank surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

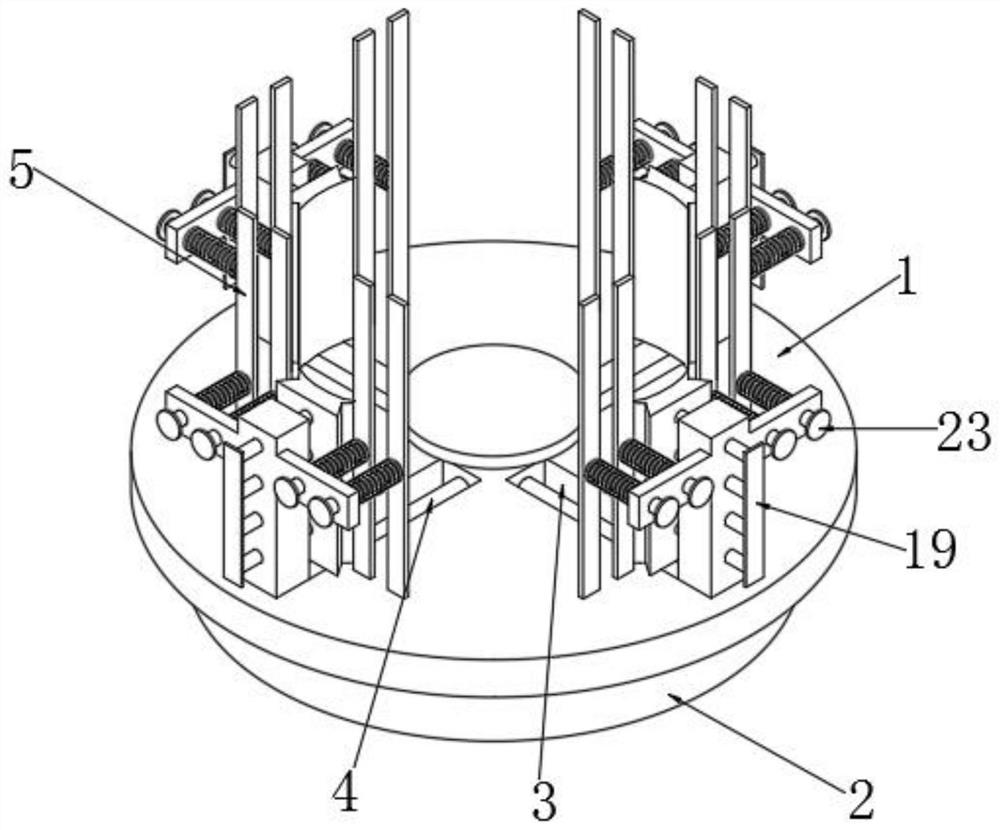

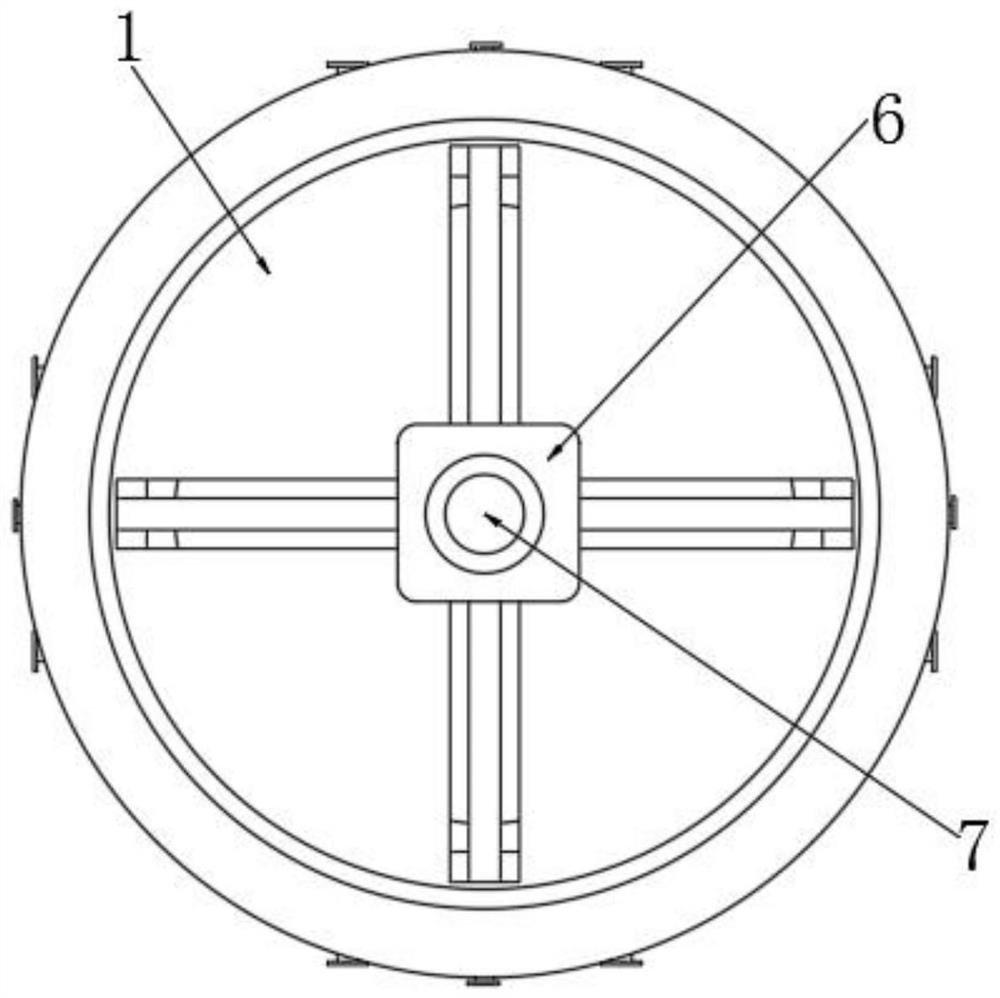

[0028] As an embodiment of the present invention, the number of the chute 3 is 4, and the angle between the adjacent chute 3 is 90°, which is convenient for limiting and fixing the tank body from multiple angles.

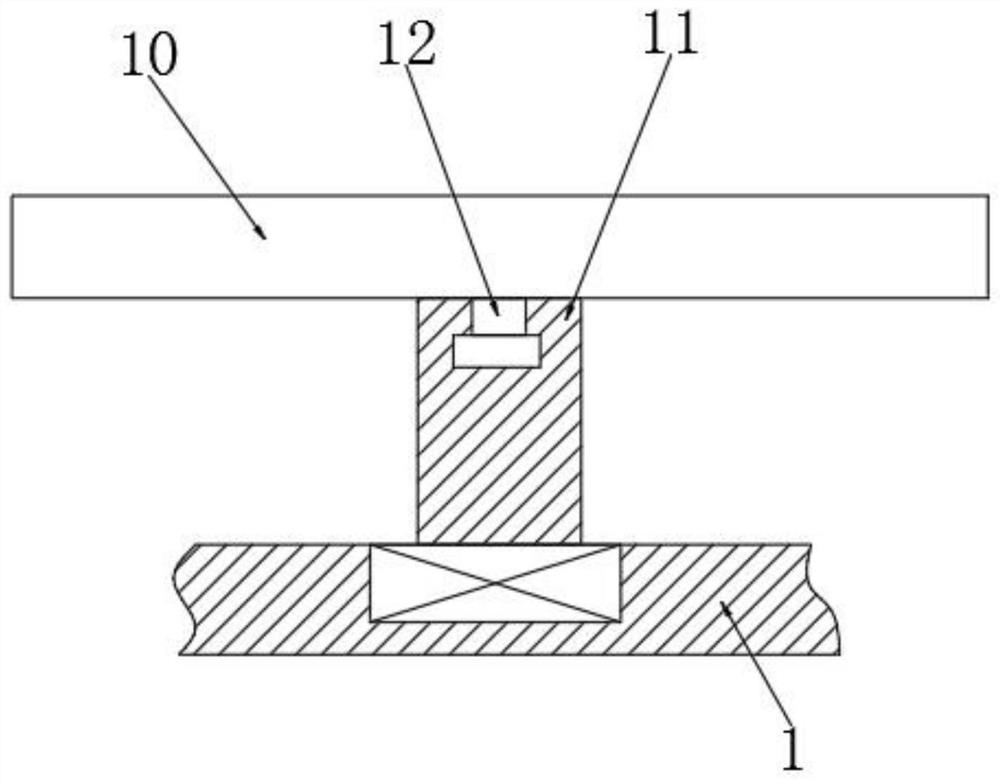

[0029] As an embodiment of the present invention, a ring-shaped base 2 is installed on the bottom side of the mounting plate 1, a reducer 6 is installed in the middle of the bottom side of the mounting plate 1, and the input end of the reducer 6 is connected to the servo motor 7. The output end is connected, the output end of the reducer 6 is installed with a main bevel tooth 8 inside the installation disk 1, a threaded rod 4 is installed inside the chute 3, and a slave bevel tooth 9 is installed at the inner end of the threaded rod 4, And the secondary bevel teeth 9 are all meshed with the main bevel teeth 8, the bottom side of the sliding column 13 is provided with a slider, and the slider is threaded with the threaded rod 4, and the slider is matched with the chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com